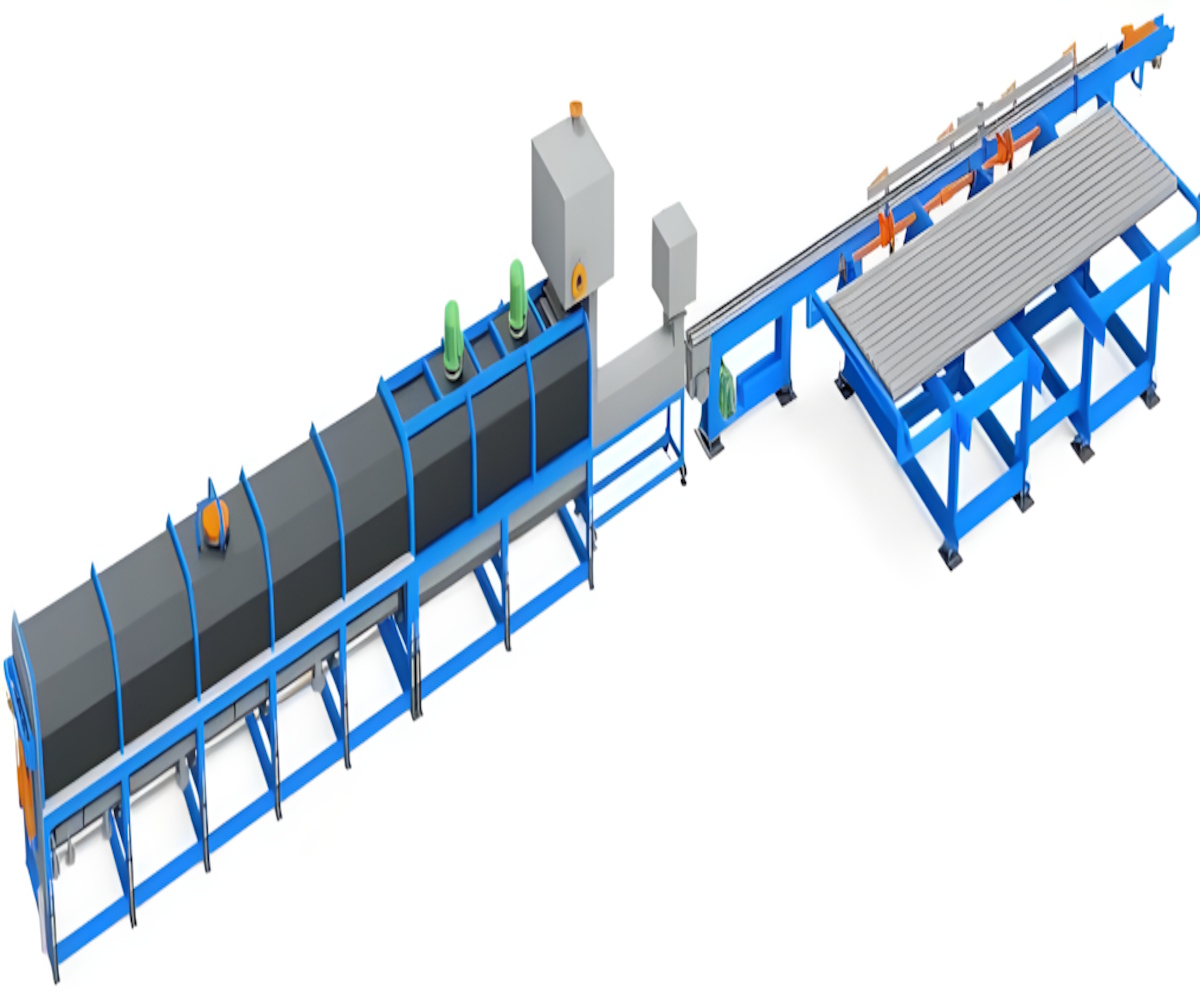

Aluminium Billet Heating Furnace

By: Acar Teknolojik Sistemler San. ve Tic. Ltd. Sti.| Price | Available on request |

| Category | Heat Treatment Furnace |

| Manufacturer | Acar Teknolojik Sistemler San. ve Tic. Ltd. Sti. |

| Min Order Quantity | 1.00 Unit |

| Delivery Lead Time | As per order |

| Place of Origin | Turkey |

| Supply Ability | Customization as required |

| Packaging Details | Standard export packing |

| Transportation Details | Road / Ship |

Description

These furnaces heat aluminium billets to 450°C before extrusion. Billets loaded into the furnace from the loading stand are first heated to approximately 250°C in the preheating section by reusing flue gases with the aid of circulation fans. They are then heated to 450°C in the main heating section using PLC-controlled proportional premix nozzle burners. The furnace temperature is measured in 3-4 zones, depending on the furnace capacity, using thermocouples that directly contact the billet surface. If the billet reaches the desired temperature at the furnace exit, the furnace door opens and the hot billet is transferred to the press. All temperature and motion controls within the furnace, as well as communication with the existing press, are handled via the PLC.

Other Products

You may be interested in

Post requirements