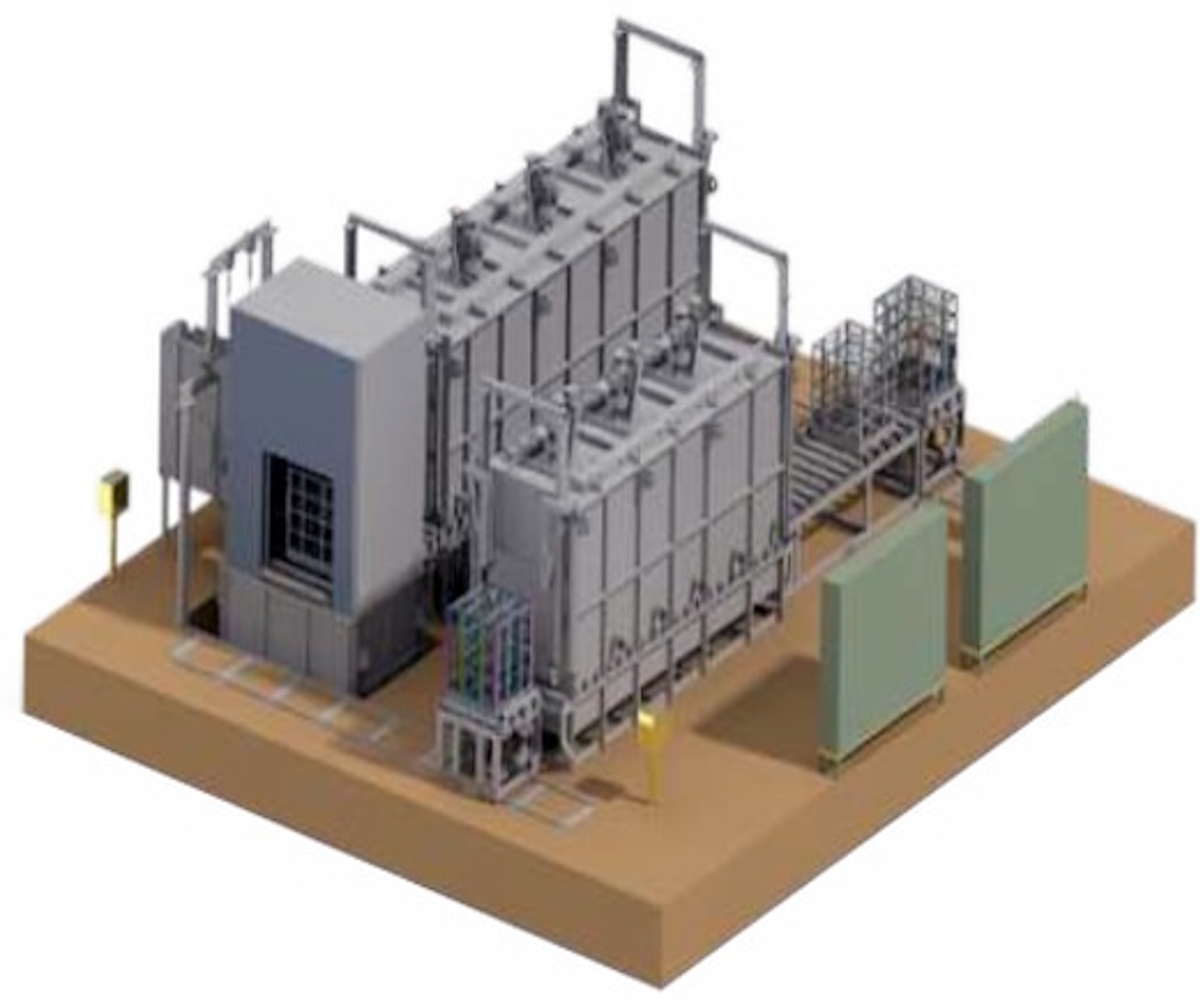

Hydraulic Tilting Furnace

By: Furnteck Engineers Private Limited| Price | Available on request |

| Category | Melting Furnace |

| Manufacturer | Furnteck Engineers Private Limited |

| Min Order Quantity | 1.00 Unit |

| Delivery Lead Time | As per order |

| Place of Origin | India |

| Supply Ability | Customization as required |

| Packaging Details | Standard export packing |

| Transportation Details | Road / Ship |

Description

The hydraulic tilting furnace, manufactured by them, is designed to provide efficient melting solutions for a variety of industrial applications. This innovative furnace combines advanced hydraulic technology with a robust construction, ensuring high performance and reliability in metal melting processes.

Industries That Use It:

Hydraulic tilting furnaces are utilized across several industries, including foundries, metal processing plants and recycling facilities. These sectors benefit from their ability to handle various metals, such as aluminium, copper and alloys, making it an essential piece of equipment in manufacturing and recycling operations.

How It Works:

The operation of the hydraulic tilting furnace is based on a hydraulic system that allows for precise tilting of the furnace body. This feature facilitates the controlled pouring of molten metal into molds or casting machines. The furnace is heated using electric or gas-fired burners, efficiently reaching the desired melting temperature for different metals. Once the metal is melted, the hydraulic system allows the operator to tilt the furnace and pour the molten metal with ease and accuracy.

Distinct Features:

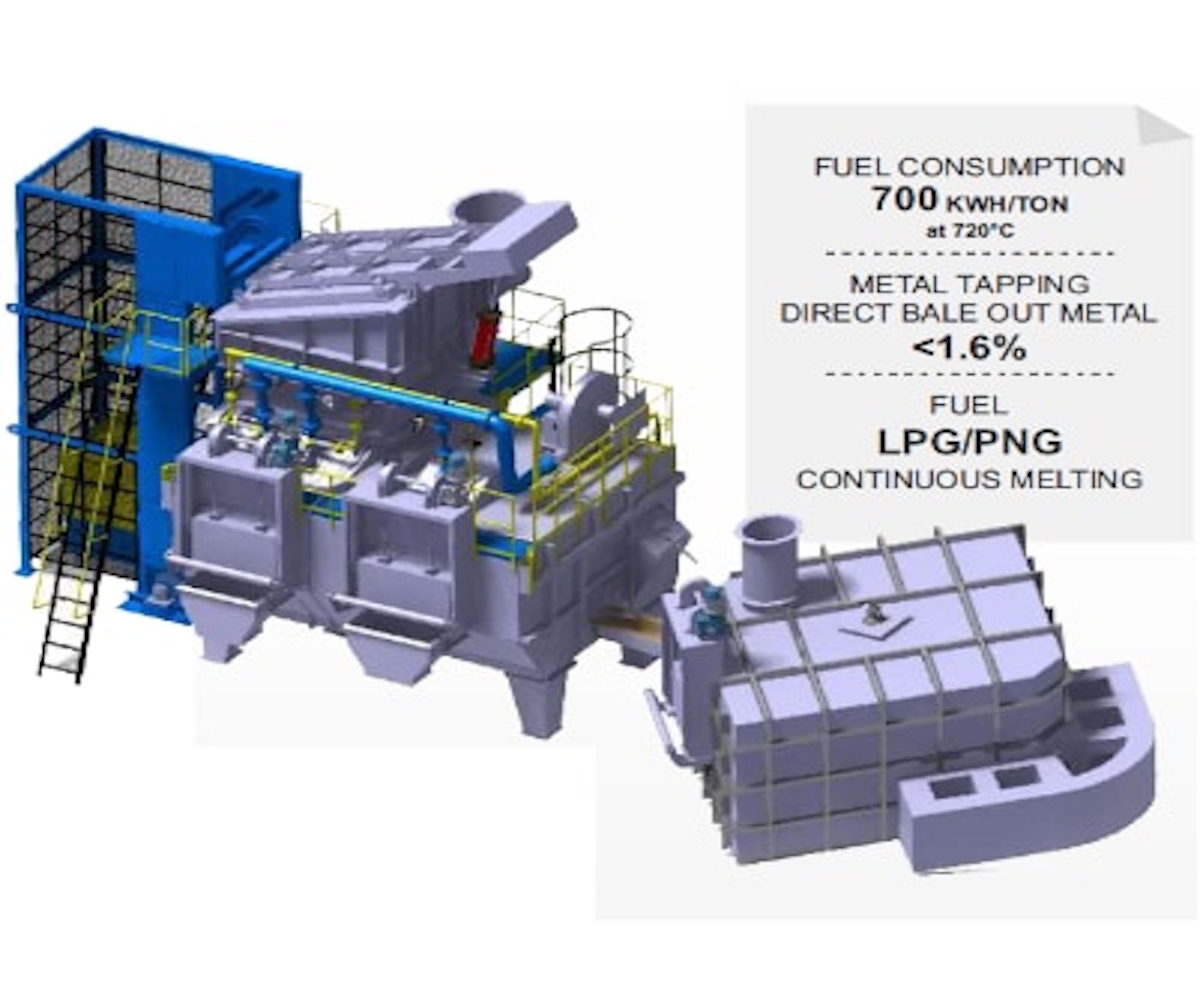

Highly energy efficient. Consumes less than 575 kWh/ton.

High metal yield (> 99.4%).

Process visualization on the control panel.

Special shaft geometry ensures optimum utilization of FLUE GASES.

A well-engineered refractory configuration ensures a long service life.

Easy to access refractory for cleaning WITHOUT ANY BLIND CORNERS.

Superior insulation ensures the lowest heat losses.

Fully automated and user-friendly combustion system and charging machine.

A robust, reliable and automated charging mechanism ensures optimum charging based on furnace demand.

Wide range of melting and holding capacities (100 kg/hr to 4000 kg/hr).

Various fuel options are available, from heavy fuel oil to natural gas.

Other Products

You may be interested in

Post requirements