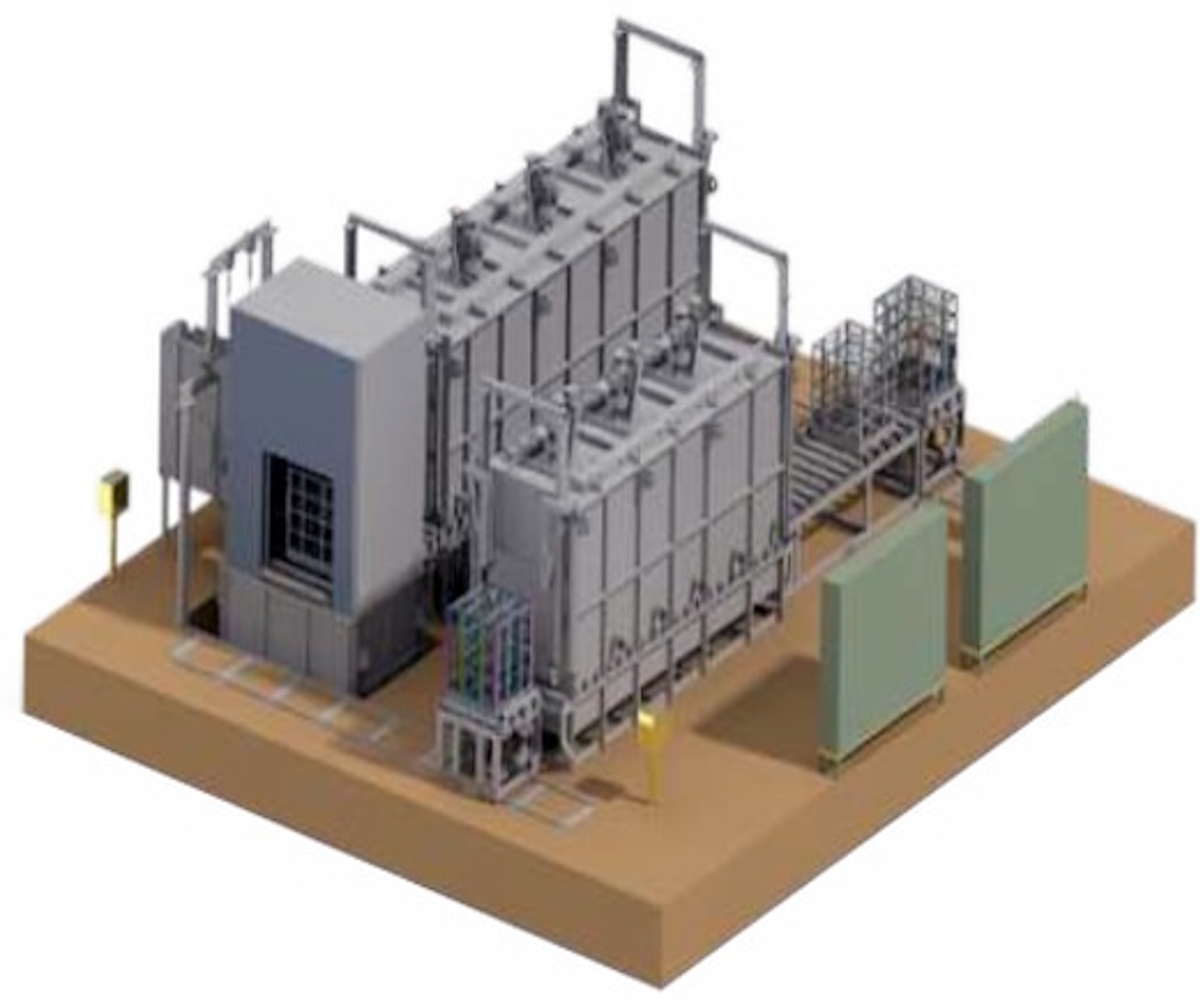

Reverberatory Furnace

By: Furnteck Engineers Private Limited| Price | Available on request |

| Category | Melting Furnace |

| Manufacturer | Furnteck Engineers Private Limited |

| Min Order Quantity | 1.00 Unit |

| Delivery Lead Time | As per order |

| Place of Origin | India |

| Supply Ability | Customization as required |

| Packaging Details | Standard export packing |

| Transportation Details | Road / Ship |

Description

Theyproudly manufacture high-quality reverberatory furnaces designed for efficient scrap melting and recycling. With a focus on energy efficiency and advanced engineering, furnaces cater to a range of needs, ensuring optimality and reliability in the melting process.

Industries That Use It:

Reverberatory furnaces are widely used in several industries, including metal recycling, foundries and aluminium production. These furnaces are particularly beneficial for scrap recycling and alloying units, where they facilitate the melting of various types of scrap metals. Industries focused on sustainable practices also utilize these furnaces to minimize waste and maximize resource recovery.

How It Works:

The reverberatory furnace operates by charging scrap metal into a single chamber where it is melted using fuel-fired burners. The design allows for both melting and holding of the metal in one unit, enhancing efficiency. The metal is tapped out through a plug system or hydraulic tilting mechanism, making the process convenient and effective. With no blind corners in the refractory lining, cleaning and maintenance are simplified, ensuring a consistent melting process.

Specification:

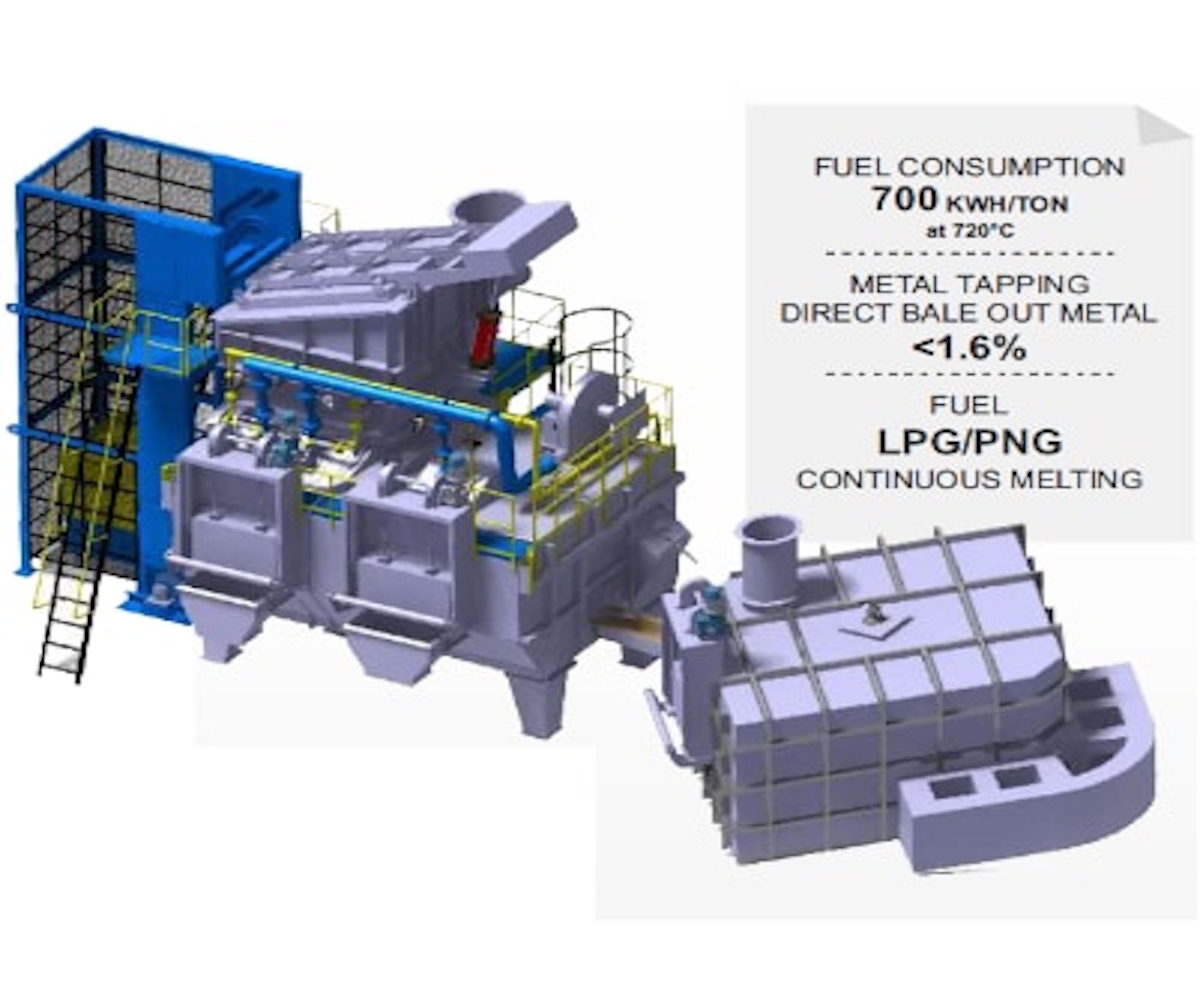

Fuel Consumption: 1000 KWH/ton at 720°C tap-out temperature.

Metal Loss: Approximately 4%, depending on the type of scrap.

Capacity: Ranges from 1000 kg/batch to 25000 kg/batch.

Loading: Available with manual or optional auto charger.

Metal Tapping: By plug system or hydraulically tilting mechanism.

Fuel Options: LDO, FO, HSD, LPG and propane.

Distinct Benefit:

Melting and holding are done in a single chamber.

No blind corners in the refractory, which allows easy and thorough cleaning of the furnace.

Metal tapping is possible through the plug system/hydraulic tilting.

The furnace can be optionally equipped with an air recuperator.

Large full-width door access can be provided in order to clean and charge the furnace easily.

Other Products

You may be interested in

Post requirements