Dummy Block

By: 4 EL KALIP VE MAKİNA SAN. TİC. LTD. ŞTİ.| Price | Available on request |

| Category | Spare Parts |

| Manufacturer | 4 EL KALIP VE MAKİNA SAN. TİC. LTD. ŞTİ. |

| Min Order Quantity | 1.00 Unit |

| Delivery Lead Time | As per order |

| Place of Origin | Turkey |

| Supply Ability | Customization as required |

| Packaging Details | Standard export packing |

| Transportation Details | Road / Ship |

Description

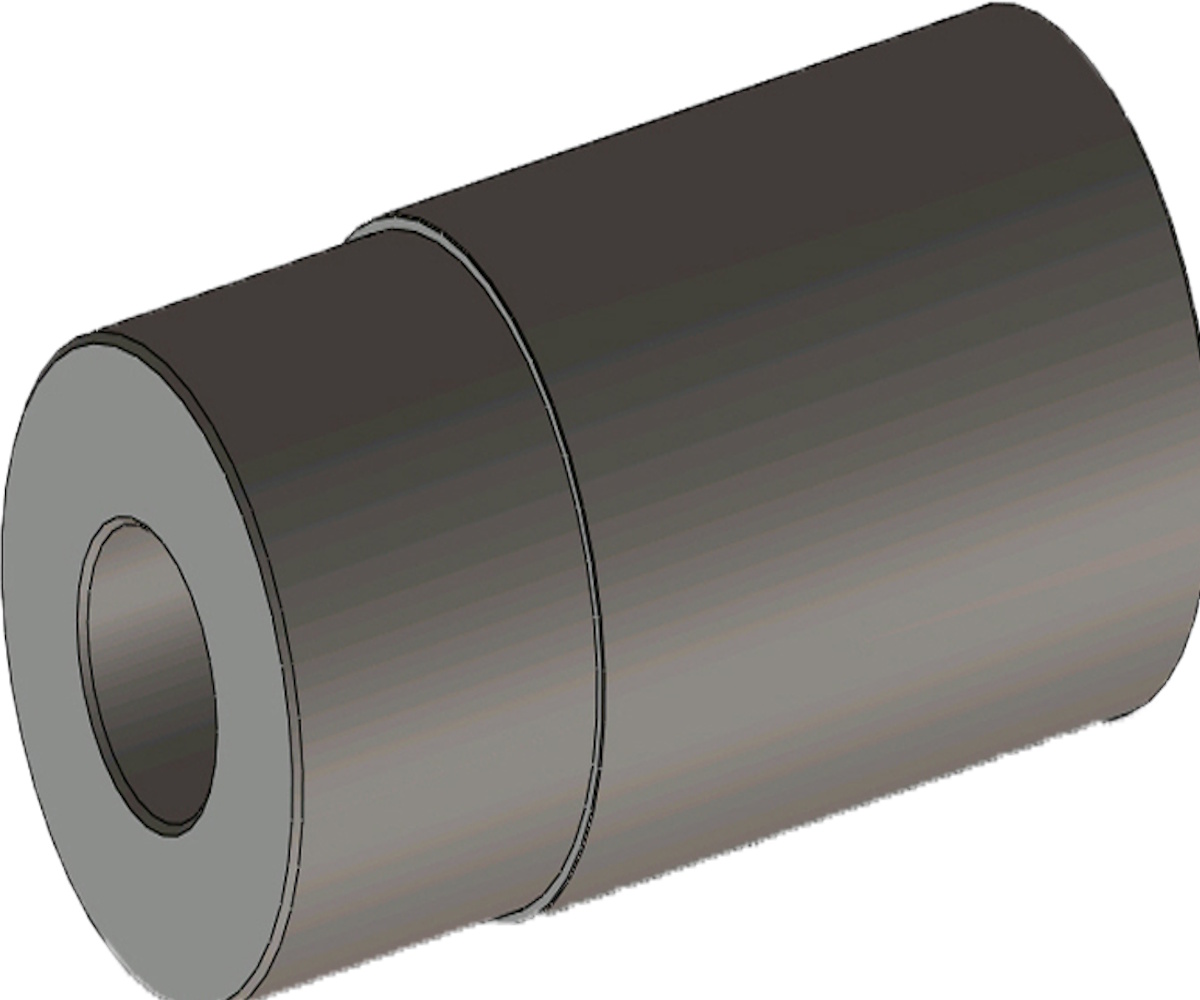

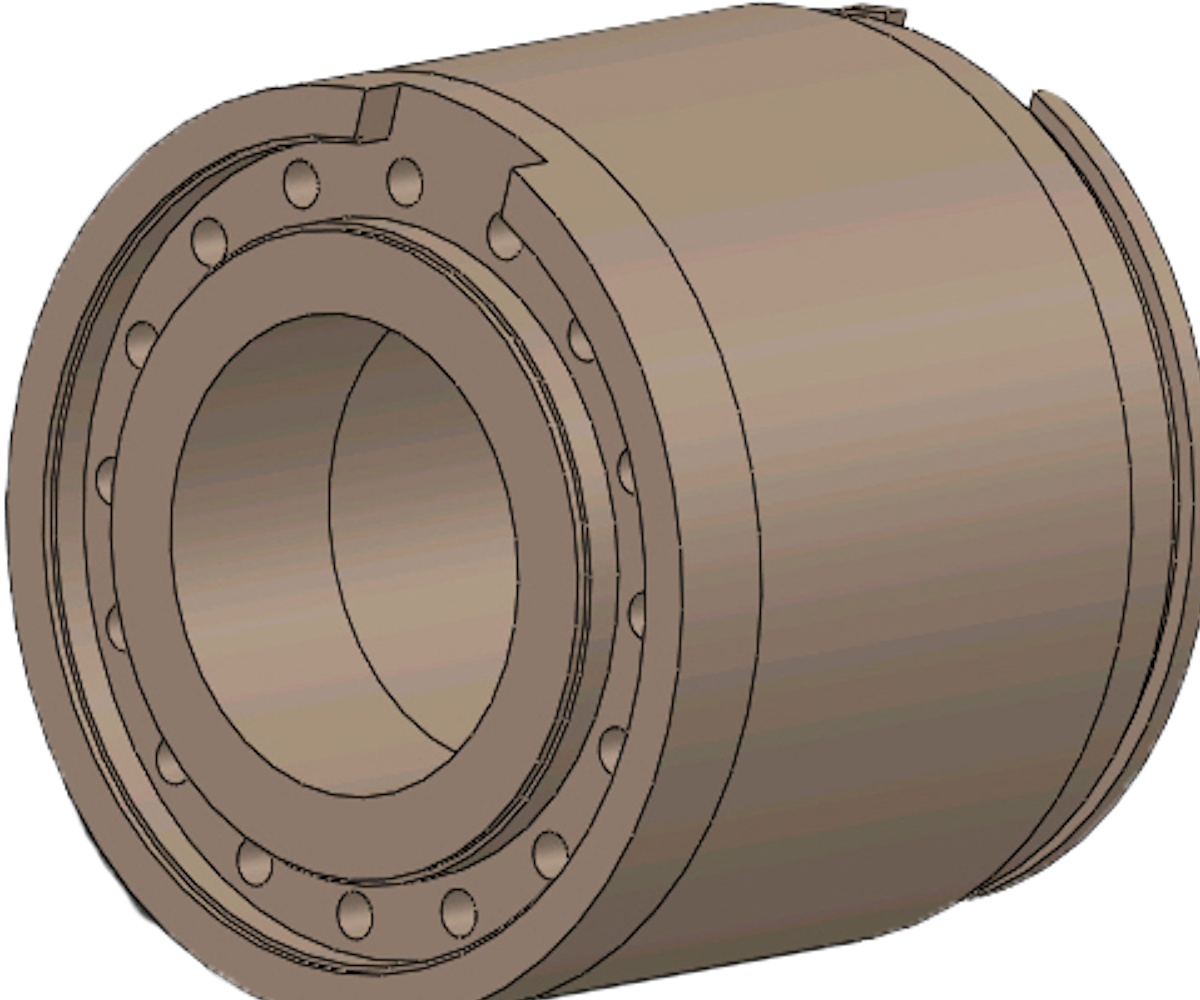

The task of the dummy block seems easy at first sights, it is the part which is placed on the tip of the punch and which pushes the billet through the core to provide that it is taken out of the die. Actually, the efficiency and quality in aluminium profile production depends on the dummy block. The dummy block is continuously exposed to high temperatures, temperature variations, pressure and mechanical stresses. Wear and tear in dummy blocks is regarded as normal; however the main problem is their very fast wearing. If the dummy block experiences a rapid wear, this decreases the performance of the whole system insomuch that it might cause it to shut down. A high operation cost merges as a result. It is essential to provide the suitable conditions, such as an accurate centring of press, proper operating temperature, lubrication and regular maintenance, in order that the dummy block operates with a good performance. In addition to these conditions, yet much more important is that there should be a sleeve with a homogeneous temperature distribution.

A properly operating dummy block transfers the power from the main cylinder to the high-temperature billet by means of the punch. This process is repeated over and over. The dummy block expands rapidly during the ring pressure and stops at such a distance that it leaves an aluminium film layer on the core wall. A properly operating dummy block does not cause any stripping on the core wall for it closes up rapidly when returning. Besides its easy assembly-disassembly and maintainability features, the Extra Dummy block prevents the billet from going behind the one-side-worn ring by means of moving with the undesirable core contacts during the pressure by virtue of the “freemove” feature of the ring.

Other Products

Post requirements