Description

Aluminum has a wide range of uses in the construction, automotive, packaging, defense industry, paint and transportation industries with its lightness, strength, superior corrosion resistance, high degree of heat and electrical conductivity, easy shaping, processing and heat treatment properties that other metals cannot provide. Therefore, it is the second most produced metal after iron and steel.

It is obtained from bauxite ore consisting of aluminum, iron oxide and aluminum oxide, which is not found in pure form in nature.

There are various methods for obtaining pure aluminum from bauxite ore. Among these methods, the Bayer method, which was discovered by Carl Bayer, is still the most widely used method in the world. In the first stage of pure aluminum production from ore; Alumina (Al2O3) is obtained from bauxite ore by Bayer method, and pure aluminum is obtained from alumina by electrolysis method in the second step. About 4 tons of bauxite; 2 tons of alumina, 1 ton of metal aluminum can be obtained. Today, the demand for secondary aluminum obtained as a result of the reuse of scrap metal is increasing in parallel with high energy costs and environmentalist approaches. While energy costs constitute approximately 40% of the cost in primary aluminum production; In secondary aluminum production, the share of energy in total costs is around 5%.

The aluminum scraps that have completed their economic life, which we supply from domestic and abroad, are processed in our facility of 6000 m2 in total, 3000 m2 closed and 3000 m2 closed, in İzmir Torbalı Subaşı Ağırsanayi region.

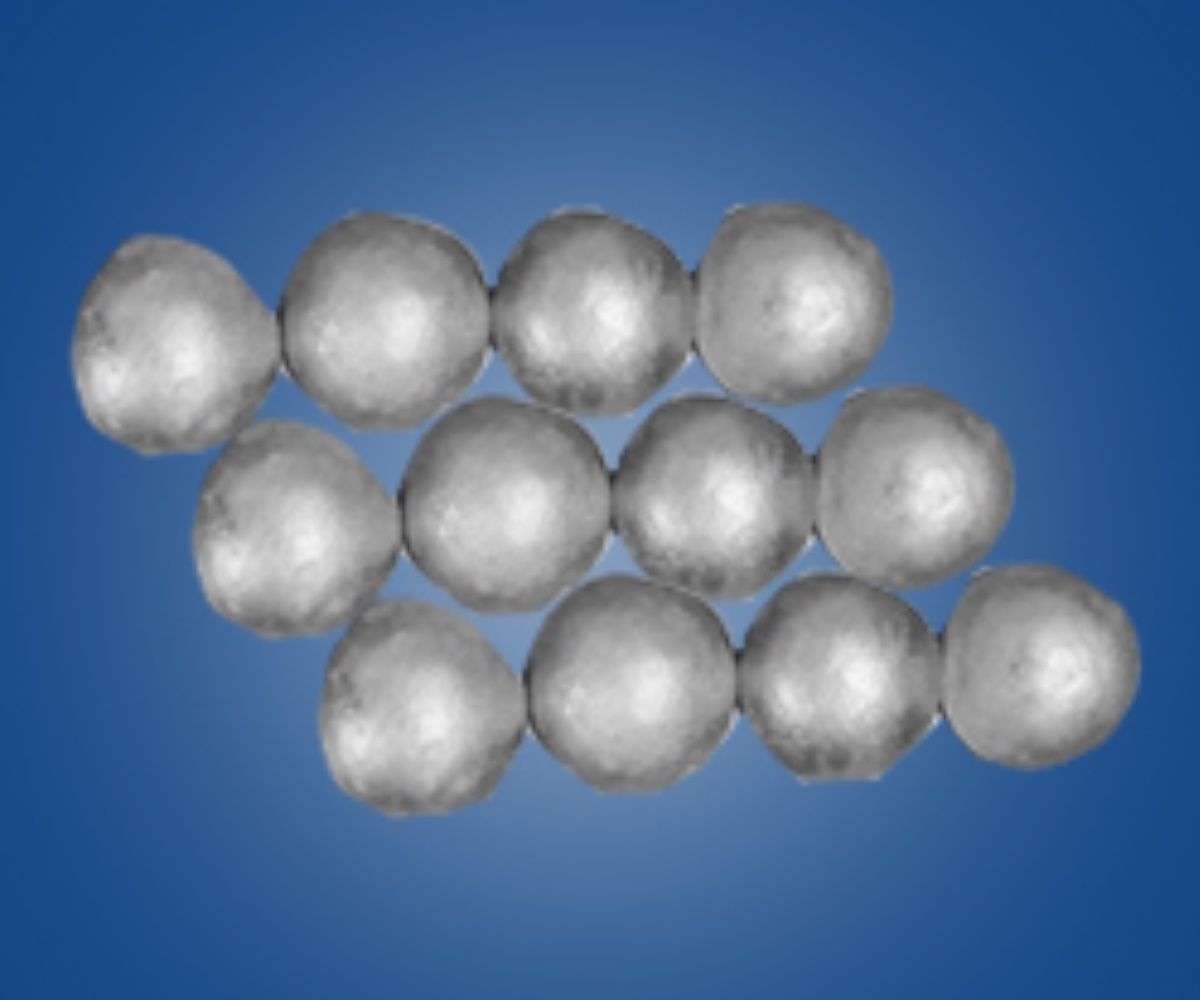

Scrap aluminums are sorted and cleaned before melting. With this process, scraps are purified from substances such as dust, paint and oil. Purified scraps are melted in our crucible tilting furnaces with the contribution of the dry filters used in emission without any harm to the environment. The metal, which becomes liquid as a result of the melting process, is subjected to refining and degassing processes. Aluminum, which becomes liquid with these processes, is cleaned from the oxides and inclusions in its content. The liquid aluminum casting process, which has increased metal quality, is made into a hemisphere.