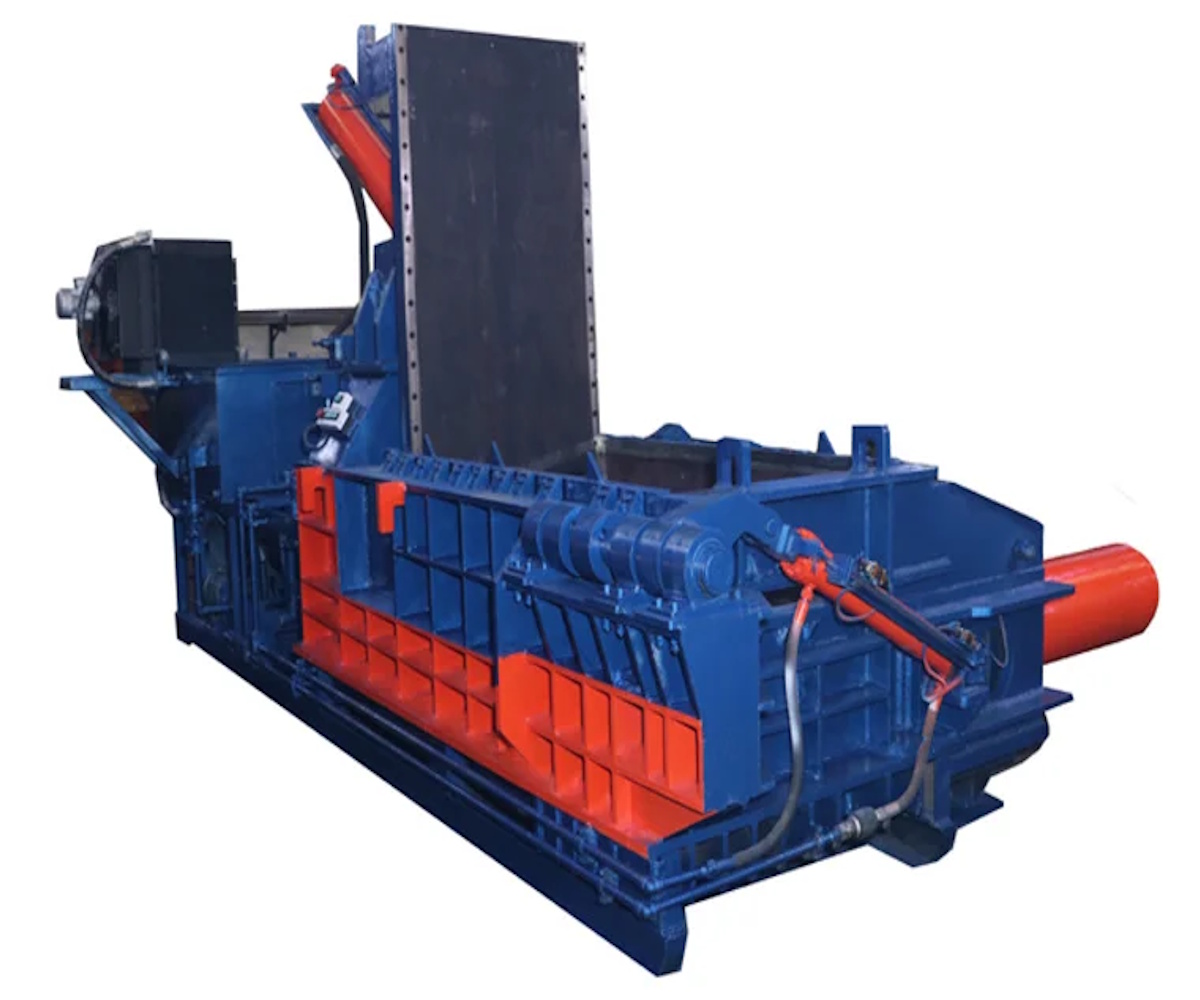

Shredders

By: Advance Hydrau-Tech Pvt. Ltd.| Price | Available on request |

| Types | |

| Twin Shaft Shredder/ Rotary Shaft Shredder/ Pre Shredder | |

| Hammer Mill Shredder | |

| Category | Recycling Equipment |

| Manufacturer | Advance Hydrau-Tech Pvt. Ltd. |

| Min Order Quantity | 1.00 Unit |

| Delivery Lead Time | As per order |

| Place of Origin | New Delhi, India |

| Supply Ability | Customization as required |

| Packaging Details | Standard export packing |

| Transportation Details | Road / Ship |

Description

In scrap metal recycling, metal shredders are used to reduce the size of metal scrap. Using a metal shredder is a highly efficient way of processing scrap to obtain a high value. At Advance Hydrau Tech, we build complete shredding systems for a wide variety of metal scrap such as LMS (light melting scrap), car body scrap, medium-sized commercial scrap (bicycles, rickshaw body, white goods), etc. Based on the space available with the customer, we can build either a single-line, a C-shaped or an L-shaped shredding system.Shredding systems built by us have a processing capacity of 10 tons/hour.

However, to fulfil the rising demands and needs of quicker and advanced scrap processing, we have partnered with Newell Recycling Equipment, USA, to offer shredders which have a processing capacity of up to 30 tons/hour. Our aim is to provide our customers with a cost-effective and technologically advanced solution.Shredders built by us are easy to operate. They can be operated automatically through a PLC or electronic control panel. They possess a long service life with low maintenance needs, have an oil lubrication system to reduce the wear and tear, and have reversing systems for overload and emergency features to ensure safely.

No files available!!

Other Products

You may be interested in

Post requirements