Alusong Cladding-FEVE

By: ALUSONG| Price | Available on request |

| Category | ACP and Cladding Products |

| Manufacturer | ALUSONG |

| Min Order Quantity | 1.00 Piece |

| Delivery Lead Time | As per Order |

| Place of Origin | China |

| Supply Ability | Customization on Requirement |

| Packaging Details | Standard Export Packing |

| Transportation Details | Road/Ship |

Description

ALUSONG FEVE aluminum composite panel has high quality polyurethane as the primary coating and highly baked fluororesin as the surface coating. It has a 10-15 year weather resistance. Its colors are more brilliant and glossier than the PVDF fluorocarbon coating. The color's diversification and uniqueness make it unparalleled by other painting

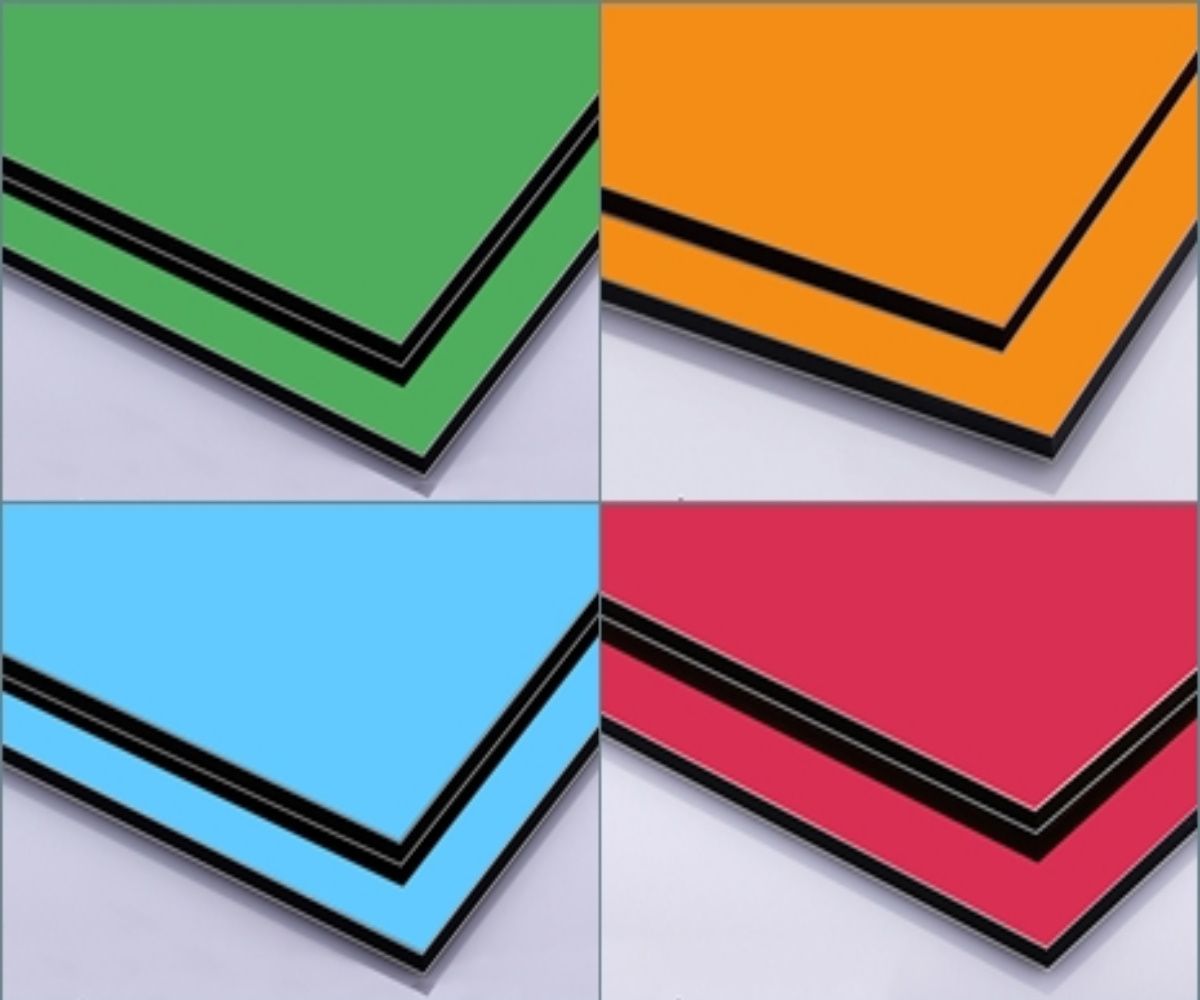

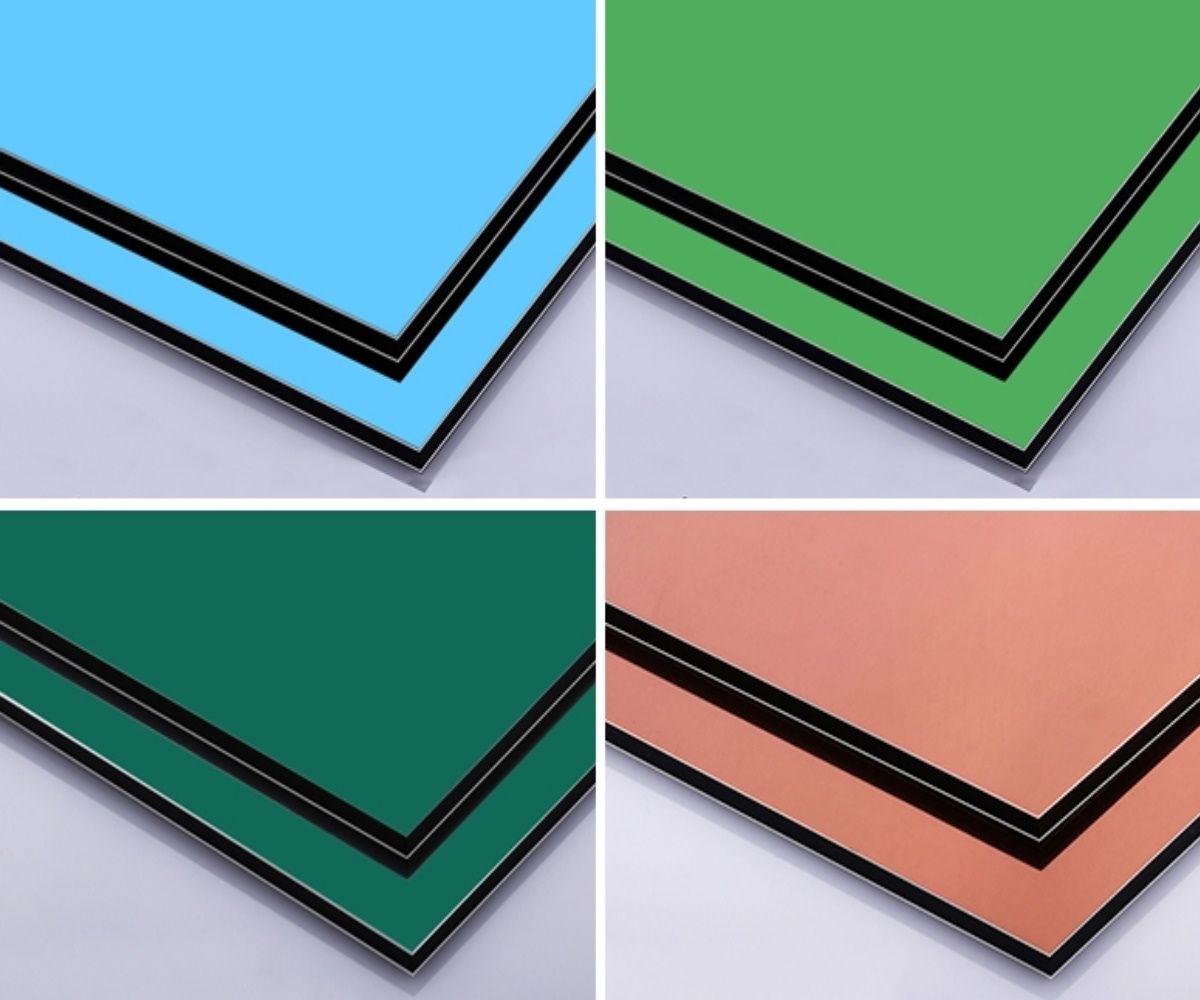

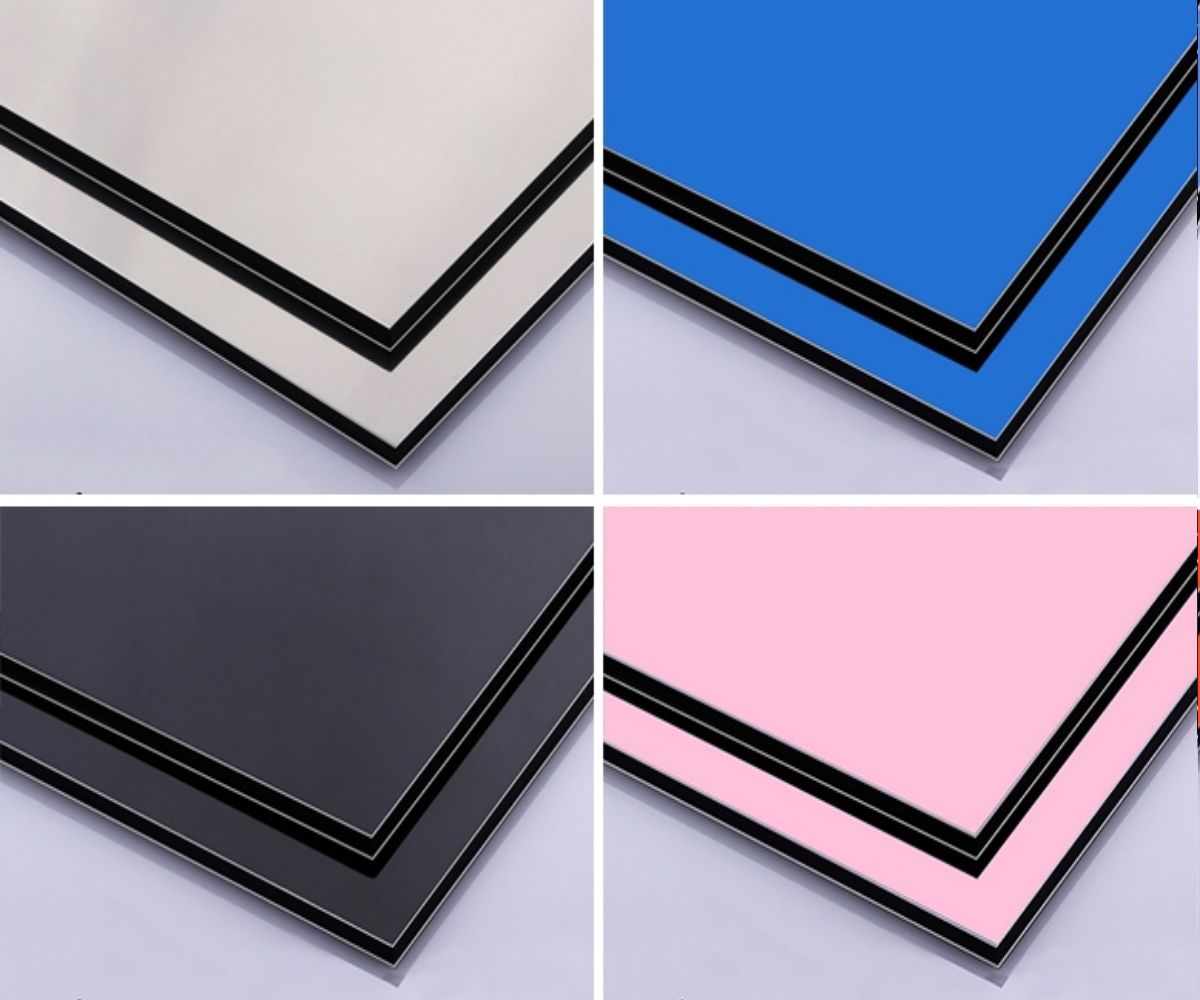

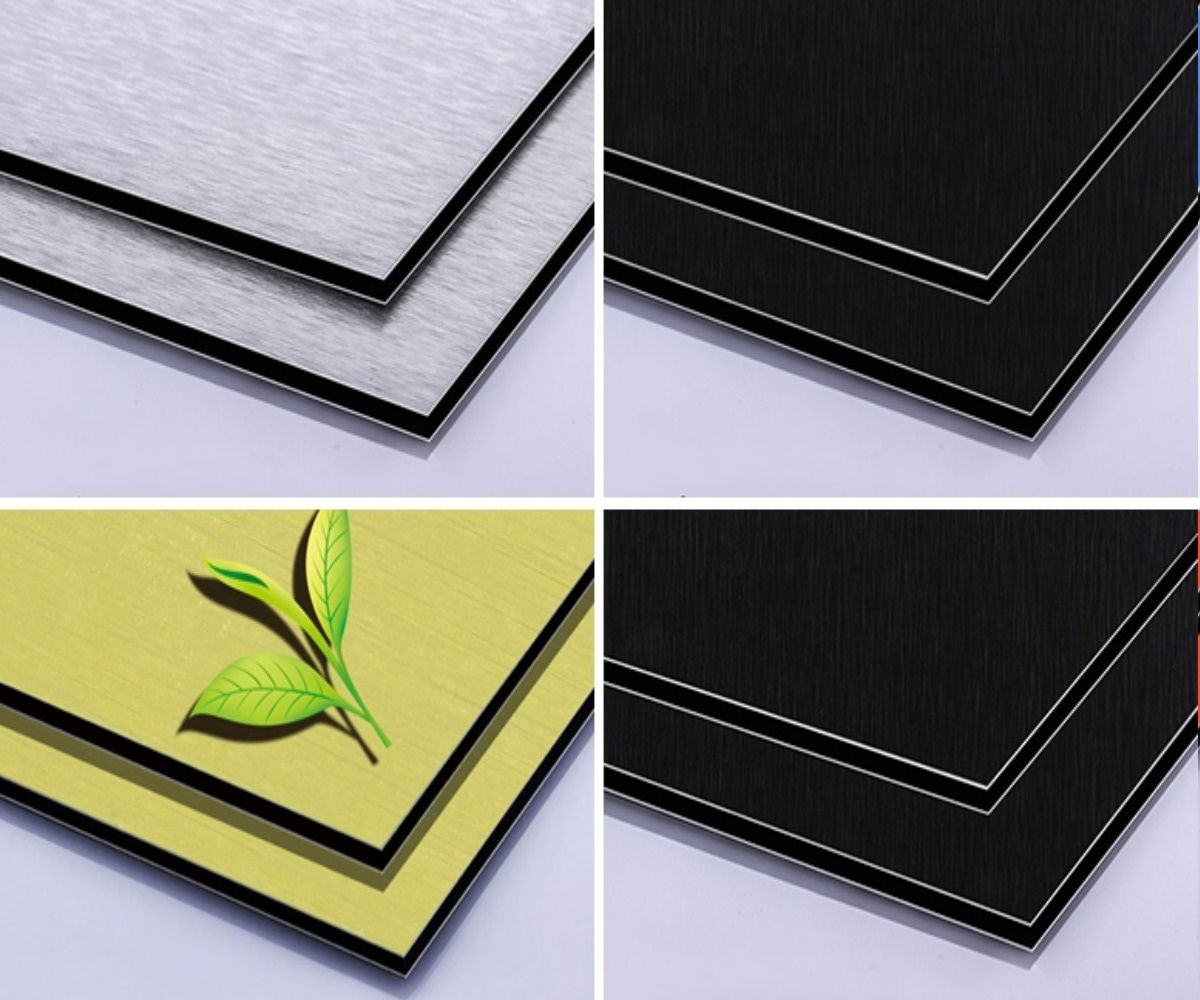

● COLORS & SURFACES

Fluoroethylene vinyl ether (FEVE) resins were developed in Japan in the early 1980’s. It is second-generation fluoropolymer coating with a similar level of durability, weatherability , adhesive force, flexibility, and color and gloss retention as PVDF coatings. The main differences between these two exterior coating technologies is that PVDF resin based coating has a limitation on the maximum gloss, it can achieve of 20%-40%, FEVE coatings on the other hand, can achieve a wider gloss range f 20%-80%. The primary applications for panels sheets coated with FEVE resins are for architectural and outdoor signage, where high gloss and durability are requested.

Raw material:

1.Base material: high strength aluminum alloy sheet

2.PE core material: non-toxic low density polyethylene

3.Surface coating: FEVE coating

4.Back coating: primer coating

PRODUCT PROPERTIES:

*With high glossy and Vivid colors as PE coating

*With high weather resistant as PVDF coating

*High surface hardness ,Pencil hardness is over 4H

*Special for exterior building and sign industry

● Refer attachment for product specification & Technical data sheet

Other Products

Post requirements