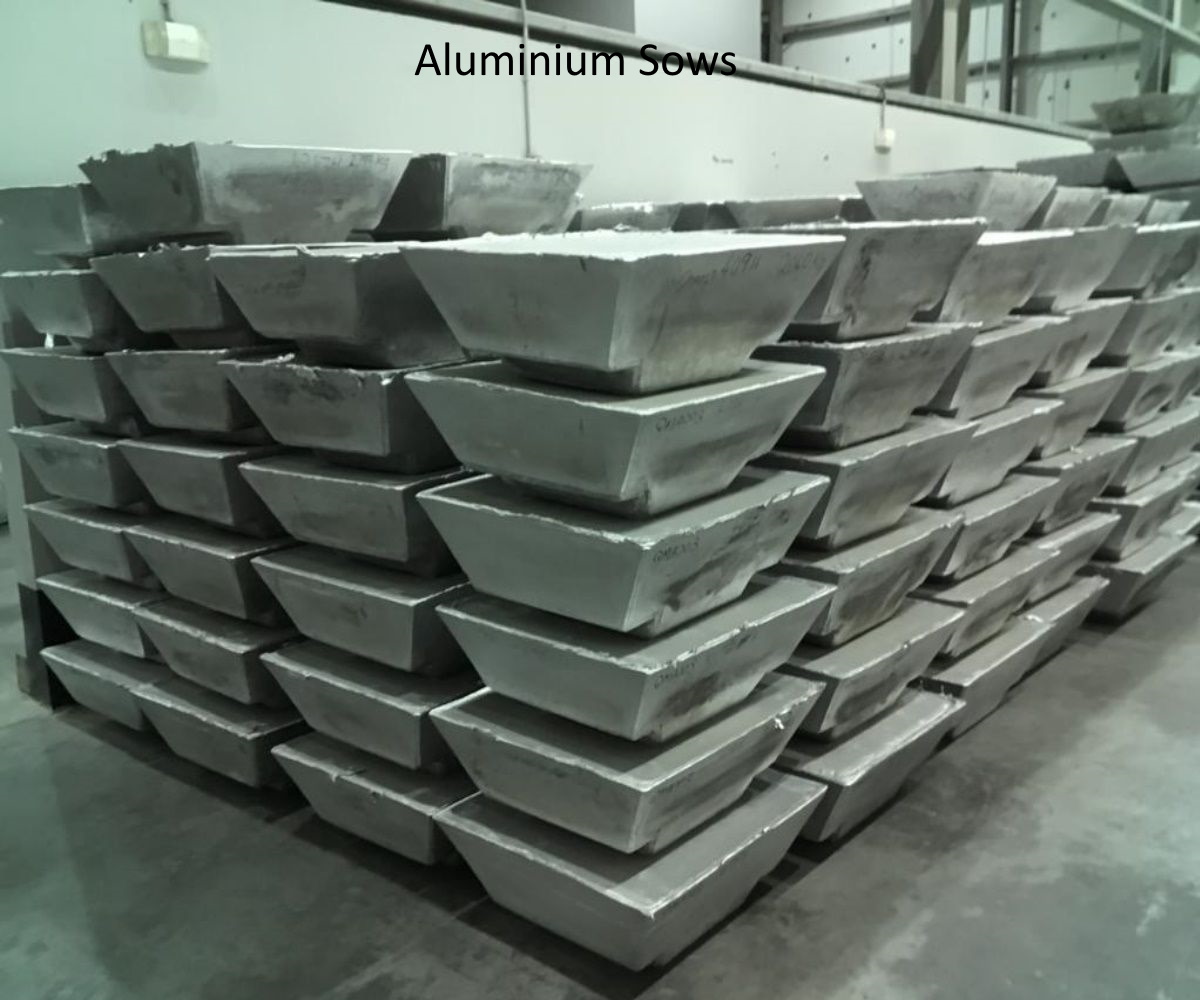

Description

Aluminium secondary sow ingots, produced from recycled aluminum scrap, play a crucial role in numerous industries due to their cost-effectiveness, eco-friendliness, and adaptability in different alloy compositions. The production process involves gathering and melting scrap aluminum, refining it to purge impurities, and casting it into sow ingot forms for reuse. This method promotes a circular economy and consumes less energy than primary aluminum production from bauxite ore. Using secondary aluminum sow ingots, industries can maintain high-quality material utilization without sacrificing material properties. We blend primary aluminum (remelt ingot or liquid metal) with scrap to forge sow ingots for wrought aluminum production, selecting a variety of scrap to minimize costs.

| Grade |

Weight |

| 98.5% Min |

250 kgs |

| 98% Min |

500 kgs |

| 97.5% Min |

|

| 97% Min |

|

| 96% Max |

|

| Grade |

Mg |

Si |

Fe |

Cu |

Zn |

Mn |

Others |

Al |

| 98.5% Min |

0.20% Max |

0.60% Max |

0.40% Max |

0.15% Max |

0.20% Max |

0.15% Max |

0.10% Max |

98.5% Min |

| 98% Min |

0.20% Max |

0.30% Max |

0.40% Max |

0.20% Max |

0.15% Max |

0.50% Max |

0.10% Max |

98% Min |

| 97.5% Min |

0.25% Max |

0.30% Max |

0.60% Max |

0.25% Max |

0.25% Max |

0.80% Max |

0.15% Max |

97.5% Min |

| 97% Min |

0.25% Max |

0.40% Max |

0.60% Max |

0.40% Max |

0.50% Max |

0.80% Max |

0.20% Max |

97% Min |

| 96% Max |

0.30% Max |

1% Max |

1% Max |

0.60% Max |

0.60% Max |

1% Max |

0.30% Max |

96% Min |