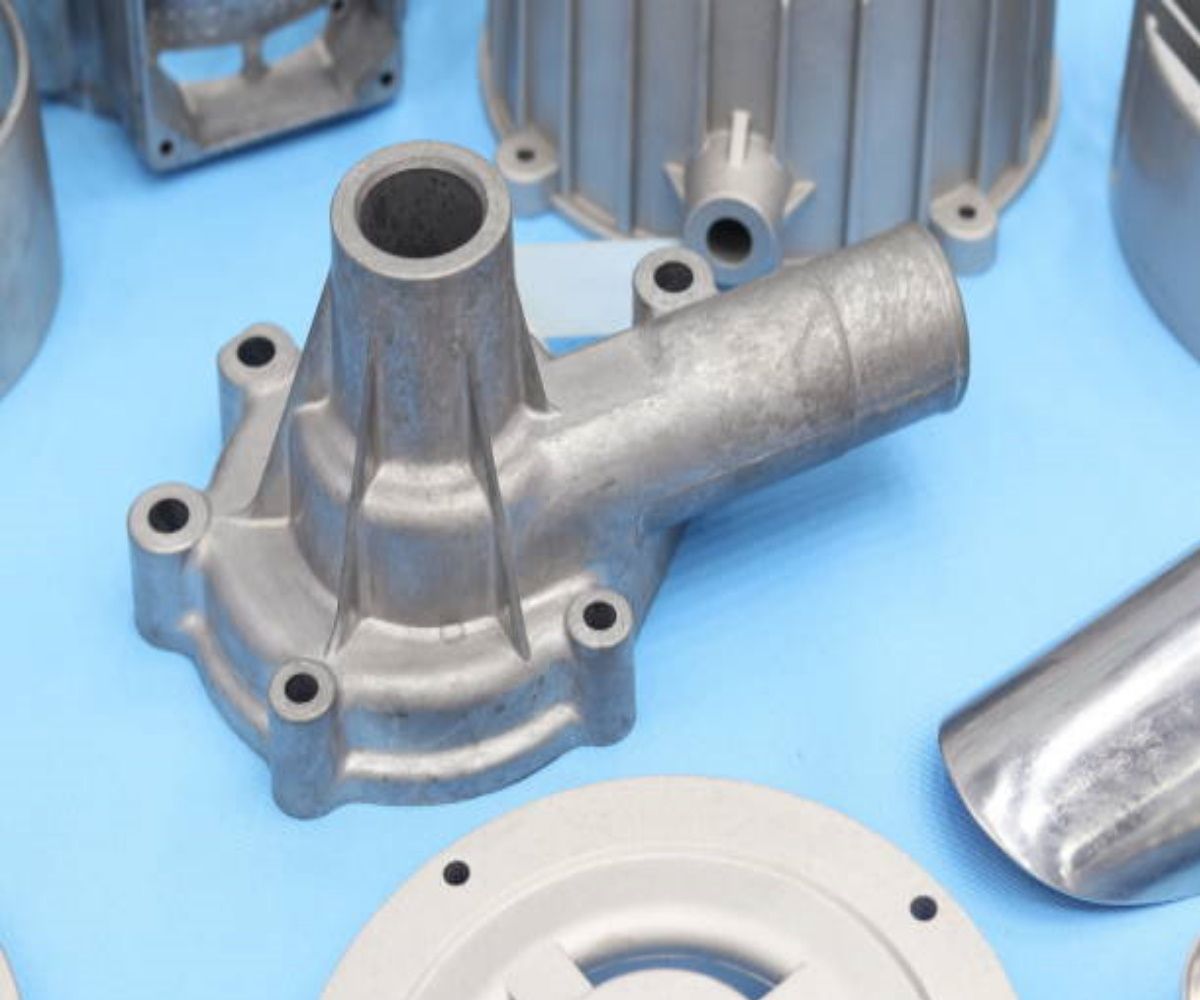

Die Casting Components Services

By: Baison Precision Metal Products Co.Ltd| Price | Available on request |

| Category | Casting and Foundry Services |

| Manufacturer | NA ( Service Provider ) |

| Min Order Quantity | 1.00 Contractual Basis |

| Delivery Lead Time | NA |

| Place of Origin | China |

| Supply Ability | NA |

| Packaging Details | NA |

| Transportation Details | NA |

Description

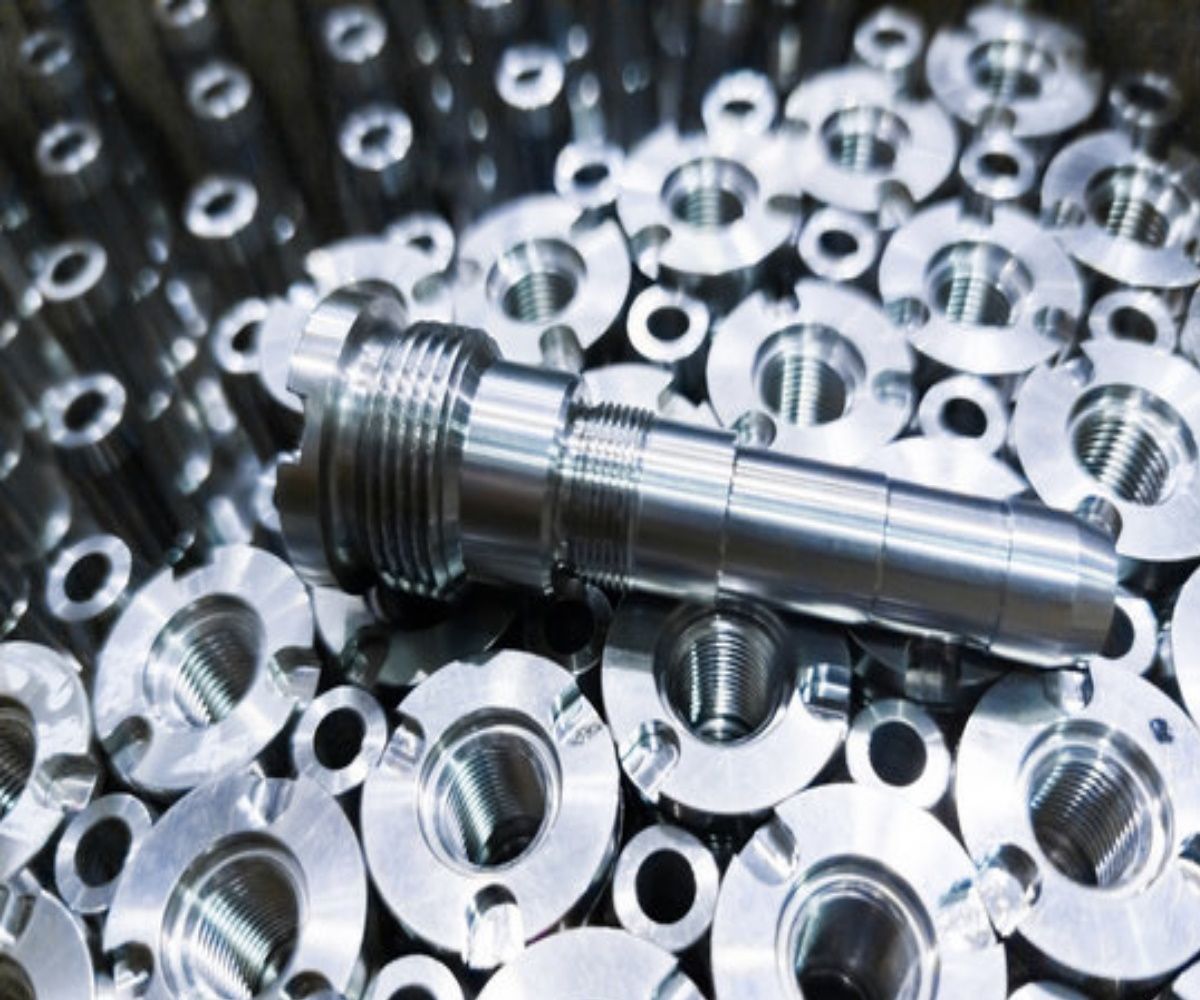

We have a range of 3 and 4-axis milling machines suitable for the machining of a variety of materials and sizes of parts.

Parts programming is carried out off-line enabling the process to be simulated and verified for optimum tool paths, prior to the machining of any material.

This ensures that we can make the parts on a number of machines, without having to re-programme.

Our approach to programming reduces the overall programming and cycle time, which helps us to stay competitive on price for our customers and achieve short lead times.

Our Milling employees have a wealth of experience and knowledge, which we continue to develop on an ongoing basis.

Advantages of CNC milling

1. Cost Efficient

80% of aspect and mechanical parts can be CNC milled within minutes or even seconds by optimizing the tool paths and using special cutting tools. With automation set up, CNC milling is super cost-efficient for mass production comparing with additive manufacturing in most of the cases.

2. Materials & Finishes Options

Besides of fast turnaround time, various type and spec of the plastic, metal block are available for milling, and different type of surface finishing is available for CNC milling parts, such as painting, anodizing and chroming. It’s great a combination of function and aspect.

3. Unlock Complexity

Because the cutting tool of a milling machine can approach the workpiece from several different angles, it is possible to create complex shapes CNC machines with more axis can create parts of greater complexity. If a CNC project demands an irregular shape, milling is often the best bet.

Other Products

Post requirements