Aluminium cans to rule the packaging industry for the next 10 years and beyond

Contributed by: Anonymous

2022-04-29

Aluminium beverage cans first came into existence when Coors Brewing Company opted for aluminium cans over existing steel containers in the 1950s to enhance the flavour of their beer. Not only the taste but Coors also focused on the sustainability part of these cans to keep their product quality, flavour, and freshness intact inside for greater end-to-end usage. During that time the can weighed around 88 grams and as a sustainable and top functional beverage can aluminium is the most admired metal by the global players. The other vital perspective of aluminium cans is that it cools fast and it gives you a 360 branding space around the neck. On the shipping and storing part, even if manhandled these lightweight cans hardly get tampered with and cause harm to the product inside. Beverages ranging from canned beers to energy drinks and sparkling water — the usage of aluminium cans is endless.

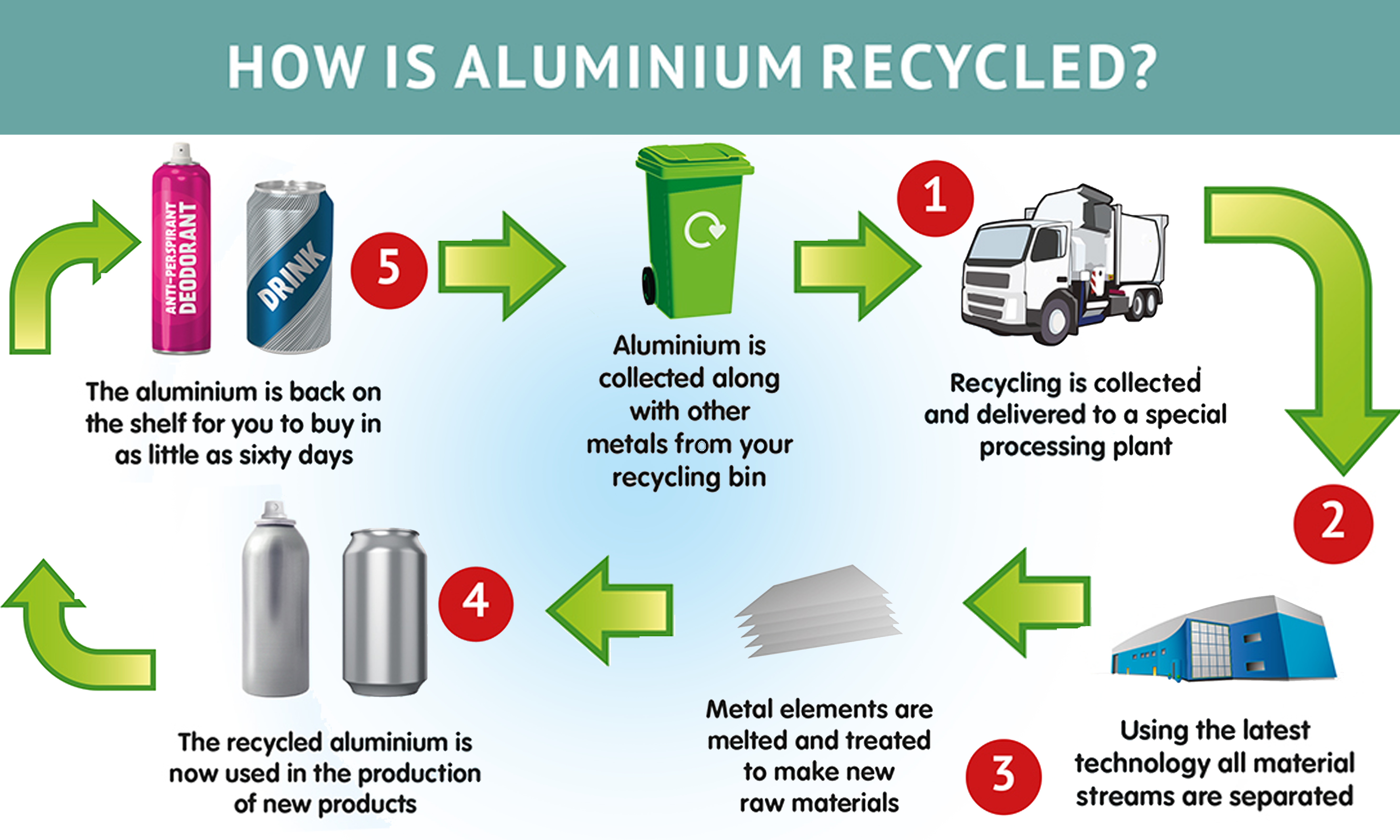

Aluminium cans surely outperform pets or any other packaging materials considering a couple of major attributes viz. sustainability and recyclability. This is the reason why the beverage industry resonantly goes with aluminium cans as containers for their products. Indeed, plastic and glass bottles are also there in the scene; but, what came out as a result of the research is compared glass and pet bottles aluminium cans have a 3X-20X higher recycling rate and others end up adding to landfills. In a way cans made of aluminium play a key role in the circular economy. However, studies suggest that over 30 billion aluminium cans are not recycled. As a result, they get transformed into bisphenol A (BPA) which slowly leaches into the environment and is found as sediments inside springs, rivers and seawater and also in soil. Another key performance indicator (KPI) of aluminium cans is they have a greater closed-loop circularity rate which means the proportion of material recycled from containers goes into the production of the same kind of products. So, practically one recycled container gives birth to another brand-new beverage can. The average 20-year consumer recycle rate of these beverage cans stands at 50% approximately. Companies have been accumulating the best of their efforts to push this rate up to 70% in the coming 10 years, 80% by 2040 and 90% by the end of 2050. The average rate of aluminium cans recycling into new products is almost double that of glass (34%), and pet (40%) and it gives higher recycled content than other competing package types. Aluminium cans are recycled over and over whereas glass and plastic get used in the carpet fiber or landfill liner. The entire process of recycling includes collection, segregation, reprocessing, thermal processing, close loop and open-loop recycling. The best part about aluminium recycling is it releases a lesser carbon footprint in the atmosphere. Multiple surveys were conducted to monitor the process of recycling glass, pet, and aluminium cans and bottles where aluminium cans have come out as undisputable champions. These day’s cans are being manufactured with a wall thickness of 0.097 mm – as thin as a single human hair. Besides the metal leaves minimum residual; this indicates that almost most of it gets back to production. Thus, all packages that require long-term unrefrigerated protection invariably go for aluminium layer packaging.

Categories

Raw Materials

Scrap

Consumables

Primary Aluminium

Secondary Aluminium

Equipment

Technology

Downstream Products

Finished Products

Utilities

Services

Others

Recent Blogs

Subscribe to newsletter

Connect with us