Innovative uses of aluminium extrusions shaping the future

Team AL Circle

2023-12-15

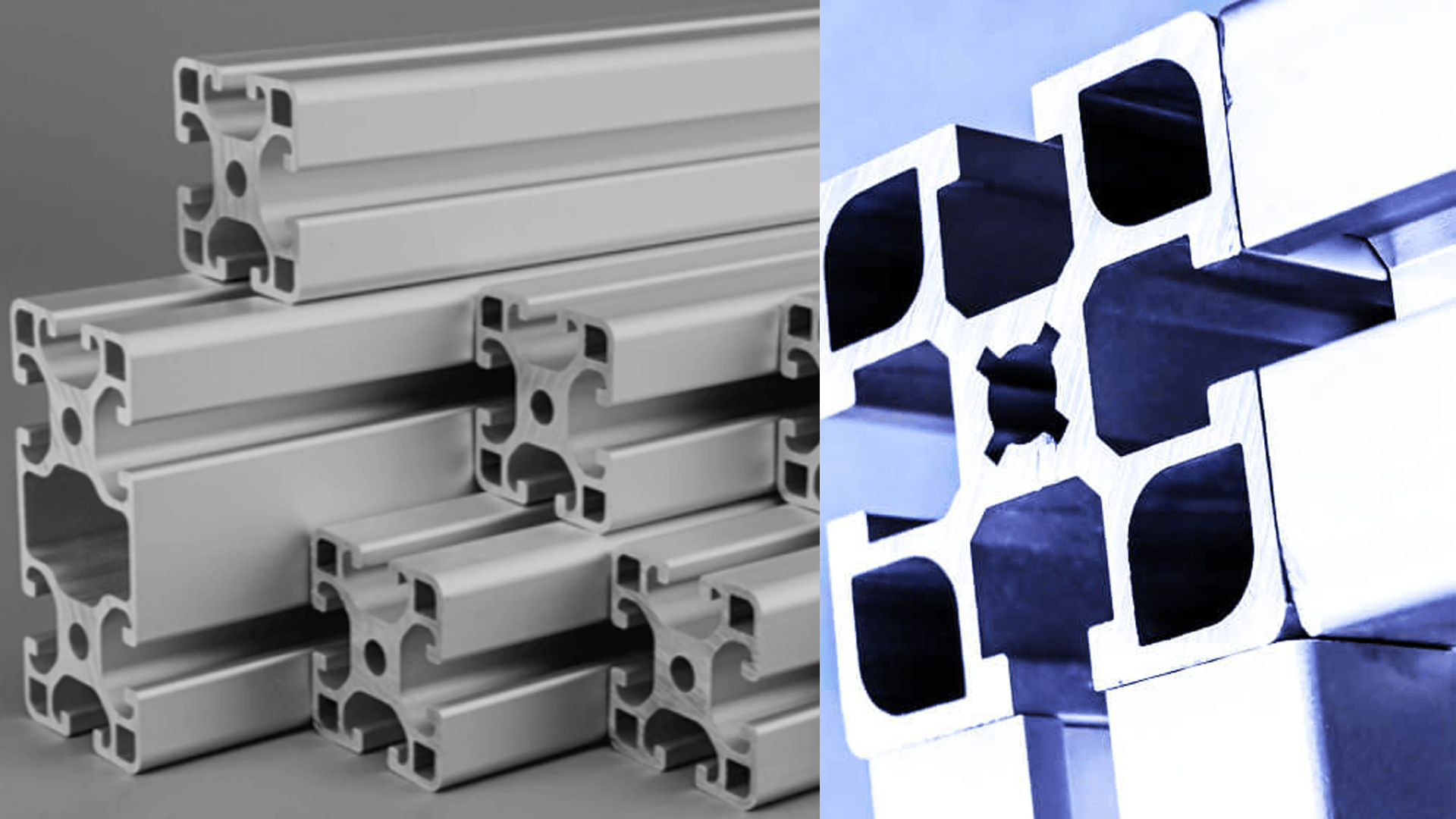

Aluminium is one of the cornerstones of the modern design and manufacturing industries. In this aspect, aluminium extrusion finds exceptional applications in domestic and commercial spheres due to its unique metallic properties.

Before we discover the innovative uses, let us ponder the specific properties that make aluminium extrusions a favourable choice for various industries.

Properties of aluminium extrusions

These properties collectively make aluminium extrusions indispensable for achieving lightweight, durable, and efficient solutions across a spectrum of innovative applications.

- Lightweight: Ideal for fuel-efficient vehicles and aerospace structures.

- Corrosion resistance: Suited for outdoor, marine, and architectural applications.

- Malleability: Enables intricate designs in architecture and displays.

- High strength-to-weight ratio: Enhances structural integrity in aerospace and automotive sectors.

- Thermal conductivity: Facilitates heat dissipation, crucial for LED lighting systems.

- Recyclability: Supports sustainability because aluminium is infinitely and 100% recyclable.

- Modularity: Allows easy assembly and disassembly in exhibitions and displays.

- Electrical conductivity: Benefits solar panels and electric vehicle components.

- Cost-effective: Abundance and efficient extrusion process make it affordable in mass production.

- Durability: Understands environmental challenges in various applications, ensuring long- lasting performance.

Let us discover a few of the innovative applications of aluminium extrusions that are driving this fast growth rate in the global market.

The latest aluminium extrusion uses

As we progress to a new era of innovation, the global aluminium extrusion usage is anticipated to reach 38.4 million tonnes in 2027. Its versatility, durability, and lightweight characteristics make it a staple in various industries, contributing to innovation and efficiency across a wide spectrum of applications.

1. Architectural frameworks

It serves as the backbone for modern architectural marvels. From sleek facades to intricate window designs, architects leverage extruded aluminium to create durable, lightweight, and visually appealing structures.

2. Electric vehicle (EV) components

In the world of sustainable transportation, it finds application in manufacturing lightweight and sturdy frames for electric vehicles. This contributes to enhanced fuel efficiency and extends the overall range of EVs.

3. Solar panel frames

The solar industry benefits from aluminium extrusions for constructing robust and corrosion- resistant frames for solar panels. The material's durability ensures the longevity of solar installations.

4. Aerospace components

Aluminium extrusions play a crucial role in aerospace engineering, providing a lightweight solution for components like aircraft frames, interior structures, and other critical parts, contributing to fuel efficiency and overall performance.

5. LED lighting systems

Extruded aluminium is integral to the design of LED lighting systems. It facilitates heat dissipation, ensuring the longevity and efficiency of LEDs while allowing for sleek and modern lighting fixture designs.

6. Medical equipment

In the healthcare sector, this extruded metal is utilised to manufacture lightweight and corrosion- resistant components for medical equipment, contributing to the development of advanced and portable healthcare solutions.

7. Customised automotive parts

The automotive industry benefits from aluminium extrusions for creating custom-shaped and lightweight components. From structural elements to decorative trims, extruded aluminium enhances aesthetics and performance.

8. Exhibition booths and displays

It offers versatility in crafting modular and customisable exhibition booths and displays. Its lightweight nature allows easy transportation and assembly while providing a durable framework for creative designs.

9. Marine applications

In marine engineering, this extruded metal is used to fabricate components like boat frames, masts, and railing systems. The corrosion resistance of aluminium ensures the longevity of marine structures in challenging saltwater environments.

10. Industrial automation systems

Aluminium extrusions are instrumental in constructing frames and structures for industrial automation systems. Their lightweight yet robust nature makes them ideal for creating agile and efficient machinery setups in manufacturing environments.

Latest innovations in aluminium extrusion manufacturing

The future of the global aluminium industry is well-set on the right course due to the following innovations in extrusion manufacturing - an intermediate stage connecting the upstream aluminium verticals with the downstream and end-user sectors.

3D printing

3D printing finds application in aluminium extrusion, producing complex geometries and shapes for extrusion dies, reducing time and costs.

Hot extrusion

Hot extrusion is an advanced technique involving extruding aluminium at higher temperatures to increase pliability.

Nanostructured aluminium

Nanostructured aluminium alloys exhibit superior strength and ductility. It is ideal for high- strength applications in the aerospace and automotive industries.

Synthetic extrusion

Hybrid extrusion merges traditional and additive manufacturing, where a 3D-printed core enveloped in molten aluminium is extruded.

Aluminium extrusions shaping the future

The horizon for aluminium extrusion shines with promise as cutting-edge technologies like 3D printing, hot extrusion, hybrid extrusion, nanostructured aluminium, recycling innovations, AI, and robotics emerge and redefine the modern industry. These advancements will bring more innovative uses and solidify aluminium extrusion as a highly desirable manufacturing material for a sustainable future.

Categories

Raw Materials

Scrap

Consumables

Primary Aluminium

Secondary Aluminium

Equipment

Technology

Downstream Products

Finished Products

Utilities

Services

Others

Recent Blogs

Subscribe to newsletter

Connect with us