A to Z Guide of Aluminium Surface Treatments And How to Choose the Right One

Admin

2025-06-16

If you work with aluminium extrusions, you know the surface finish can make or break your final product. But with so many treatment options available, where do you begin?

This simple guide covers the basics of aluminium surface treatments: what they are, why they matter and how to choose the right one for your project.

What Are Aluminium Surface Treatments?

Aluminium surface treatments are processes used to coat or change the outer layer of aluminium or aluminium alloys. These treatments improve appearance, protect against corrosion and prepare the surface for painting, bonding, or further fabrication.

Whether you're producing components, assembling systems, or building kits, the right finish can boost both performance and presentation.

Why Surface Treatments Matter for Fabricators

If you're cutting, drilling, assembling, or integrating aluminium profiles, you’re already adding value.

Surface treatments take that value even further:

- Corrosion protection: Makes aluminium parts last longer, especially in harsh environments.

- Improved appearance: Gives a uniform, finished look to assemblies, frames, or structural kits.

- Better performance: Some finishes add hardness, reduce friction, or improve bonding.

- Professional finish: Treated profiles look clean, consistent and ready for market.

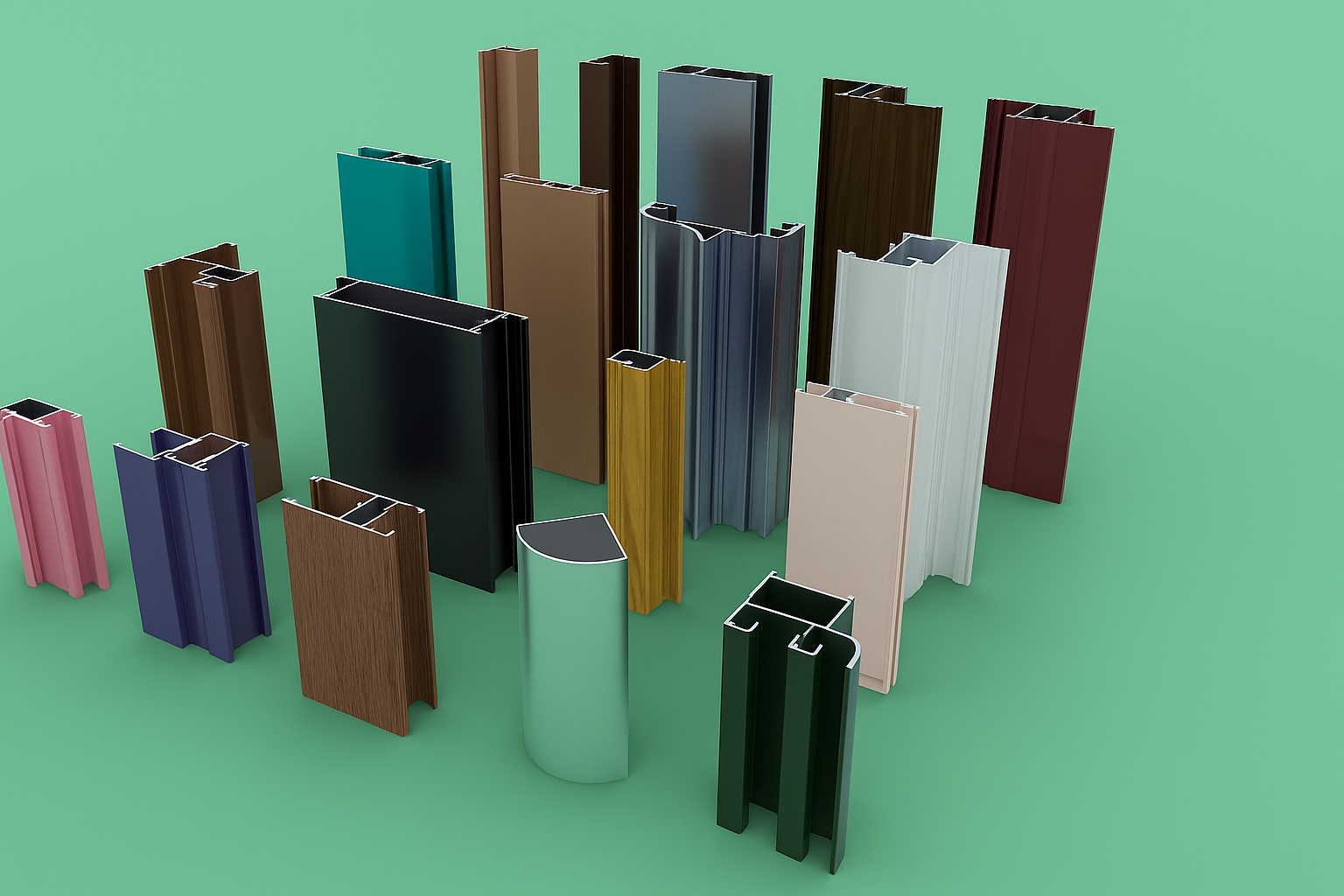

Common Types of Aluminium Surface Treatments

1. Anodising is an electrochemical process that builds a tough, protective oxide layer on the surface. It improves corrosion resistance, enhances surface hardness and can be dyed in various colours.

Application: Architectural profiles, visible components, frames and enclosures.

2. Powder coating involves applying a dry powder to aluminium and curing it in an oven. It forms a durable, coloured finish that resists wear, weather and chemicals.

Application: Structural profiles, exterior elements, window and door frames, machine guards.

3. Mechanical finishes, such as brushing or polishing, adjust the texture and appearance of aluminium. They also prepare the surface for other coatings or adhesives.

Application: Hiding small marks, adding a decorative finish, or prepping for bonding.

4. Chemical conversion coating, like Alocrom, chemically alters the aluminium surface without adding thickness. It provides mild corrosion protection and helps paints or adhesives stick better.

Application: Applications requiring tight tolerances or further processing.

5. Wet painting uses a spray-applied liquid coating. It’s useful for detailed or small-batch items where powder coating may not be suitable.

Application: Custom colours, complex shapes, prototypes and touch-ups.

How to Pick the Right Surface Treatment

Choosing the right finish for aluminium or aluminium alloys depends on your product’s use, look and requirements. Here’s what to think about:

1. Where is it going?

For outdoor use or harsh environments, choose anodising or powder coating to protect the surface and keep it looking good.

2. Does it need to look good?

If your product will be seen, go for a neat finish like coloured anodising or powder coating to give it a clean, professional appearance.

3. Is the part hidden or visible?

You don’t need to finish the whole part if only one side is visible. Use lower-cost options like chemical conversion for internal sections.

4. Will it be glued, painted or bonded later?

If yes, choose conversion coating. It won’t affect part size and improves bonding and paint adhesion.

5. Do you need tight tolerances?

Some finishes add thickness. Stick with anodising or chemical conversion for tight-fit components.

Always plan your surface treatment early. Some finishes are best applied before or after cutting and machining. Talk to your aluminium extrusion supplier at the start, as it can save time, cost and effort down the line.

Comparison: Surface Treatments at a Glance

| Surface Treatment | Key Benefits | Best For |

|---|---|---|

| Anodising | Corrosion resistance, colour options | Visible frames, enclosures and architectural use |

| Powder Coating | Durable, colourful, weatherproof | Structural kits, external components |

| Mechanical Finishes | Visual appeal, surface prep | Trim parts, bonding and aesthetic features |

| Chemical Conversion | Bonding aid, minimal thickness | Tight tolerances, hidden parts |

| Wet Painting | Flexible, cost-effective for small runs | Prototypes, complex shapes, touch-ups |

Need surface-treated aluminium profiles or components? Whether you're assembling solar panel frames, building structural systems, or producing ready-to-fit kits, the right surface treatment helps your product last longer and look better.

Stay ahead in the aluminium supply chain, and choose your fabrication technique wisely.

Categories

Raw Materials

Scrap

Consumables

Primary Aluminium

Secondary Aluminium

Equipment

Technology

Downstream Products

Finished Products

Utilities

Services

Others

Recent Blogs

Subscribe to newsletter

Connect with us