Processing and recycling aluminium radiator and automotive engine scrap

Admin

2024-10-21

The automotive industry serves as a major contributor of raw materials for the aluminium recycling industry. Aluminium is a major construction material used in the vehicles of today. Various crucial components of a vehicle are made out of this metal which can be reclaimed once the vehicle reaches the end of life. The overall recycling rate for automotive aluminium is approximately 91%1. The end of life vehicles can generate huge quantities of scrap metal which can be used for various other industrial purposes.

As the automotive industry is increasingly shifting towards lightweight vehicles, the need to recapture aluminium has become more crucial. Its lightweight and sustainable property makes it a key choice of metal for recycling. These days, a lot of advanced techniques are also being used to collect aluminium from end-of-life vehicles and convert it into a usable form. Two of the biggest sources of aluminium include aluminium radiator scrap and engines. These vital vehicle equipment pieces contain large quantities of the metal which can be converted to usable form.

Recycling aluminium radiators

A large amount of discarded aluminium radiators are produced each day as a part of the vehicle scrapping process. These discarded radiators contain valuable non-ferrous materials, and the aluminium powder generated from these scraps can be used in the aluminium recycling industry. The rapid developments in the recycling industry have given birth to various advanced procedures that are being used to recycle aluminium radiators into usable forms. Nowadays, Aluminium Taint Tabor Scrap is also being recycled to generate raw materials for the aluminium industry.

The step-by-step process involved

The scrap aluminium radiator recycling production line involves physically crushing, sorting, and recycling the scrap materials. The discarded radiators are crushed using primary crushers. They are then crushed by secondary crushers so that they can be crushed into smaller particles. The impurities are then removed through magnetic separation, and air separation is performed to enhance the purity further. The resultant product is pure aluminium that can easily be recycled.

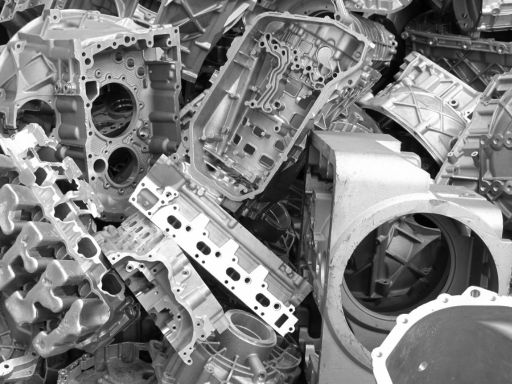

Reclaiming aluminium from engine scrap

The engines, an integral part of vehicles, are primarily composed of aluminium, a material that can be effectively recycled to generate large quantities of this metal. The recycling process, a fascinating and complex journey, unfolds through multiple steps. It begins with the detachment of engines from discarded vehicles, followed by their dismantling and processing, culminating in the production of a significant amount of aluminium.

The various stages of the recycling process:

All kinds of hazardous fluids are first removed from the engine to prevent environmental hazards. The Plant Waste Scrap Engine Aluminium Head is then dismantled and high-valued metals like aluminium are separated from the waste components. The aluminium parts are crushed, shredded, and sorted. The sorted aluminium is then melted in a furnace and then the impurities are removed. The refined aluminium can then be cast into new products.

Benefits associated with recycling automotive engine scrap and aluminium radiator

Recycling aluminium radiators and engine scrap can benefit both the environment as well as the wallet. Aluminium is a highly recycled material. It can be reused repeatedly without losing its quality. Recycling the vehicle radiators and the Automobile Engine Block Trimming Scrap can contribute to reducing the demand for primary metal production which is a much less energy-intensive process. This also helps to minimise environmental impact and conserve natural resources. Aluminium engines and radiators also do not contain other metals like copper tubing’s. This makes them more valuable than other recyclable materials.

Parting thoughts:

The aluminium recycling industry is one of the most vital industries of today. With the need for aluminium continuously on the rise, there has been an increased demand to reclaim raw materials from various industries. Aluminium being an extremely lightweight and durable material forms a key component of the automotive industry. So, the engines and radiators are being recovered from car sheds and junkyards to recover the pure metal. With the advancements being made in the fields of technology, various advanced procedures are being used to recover scrap aluminium from vehicle parts. This has increased the availability of raw materials for the recycling industry. Our need to rely on primary metal for various industrial purposes has also reduced significantly.

Categories

Raw Materials

Scrap

Consumables

Primary Aluminium

Secondary Aluminium

Equipment

Technology

Downstream Products

Finished Products

Utilities

Services

Others

Recent Blogs

Subscribe to newsletter

Connect with us