Ceramic Foam Filter

By: Drache Umwelttechnik GmbH| Price | Available on request |

| Category | Ceramic Consumables |

| Manufacturer | Drache Umwelttechnik GmbH |

| Min Order Quantity | 500.00 US $ |

| Delivery Lead Time | 8-12 Weeks |

| Place of Origin | 65582 Diez, Germany |

| Supply Ability | Available |

| Packaging Details | Individually packaged on palette |

| Transportation Details | Road / Ship / Air Freight |

Description

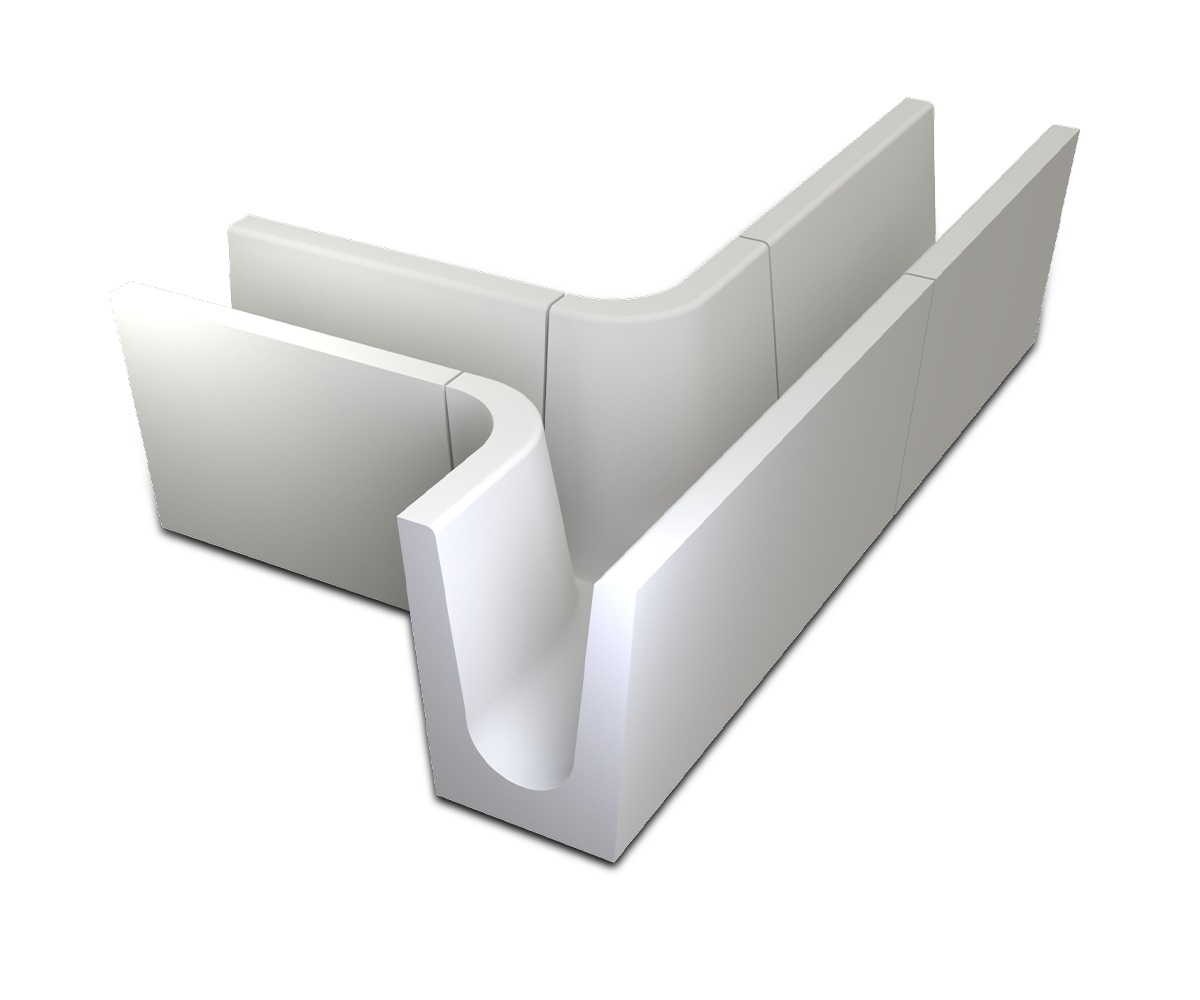

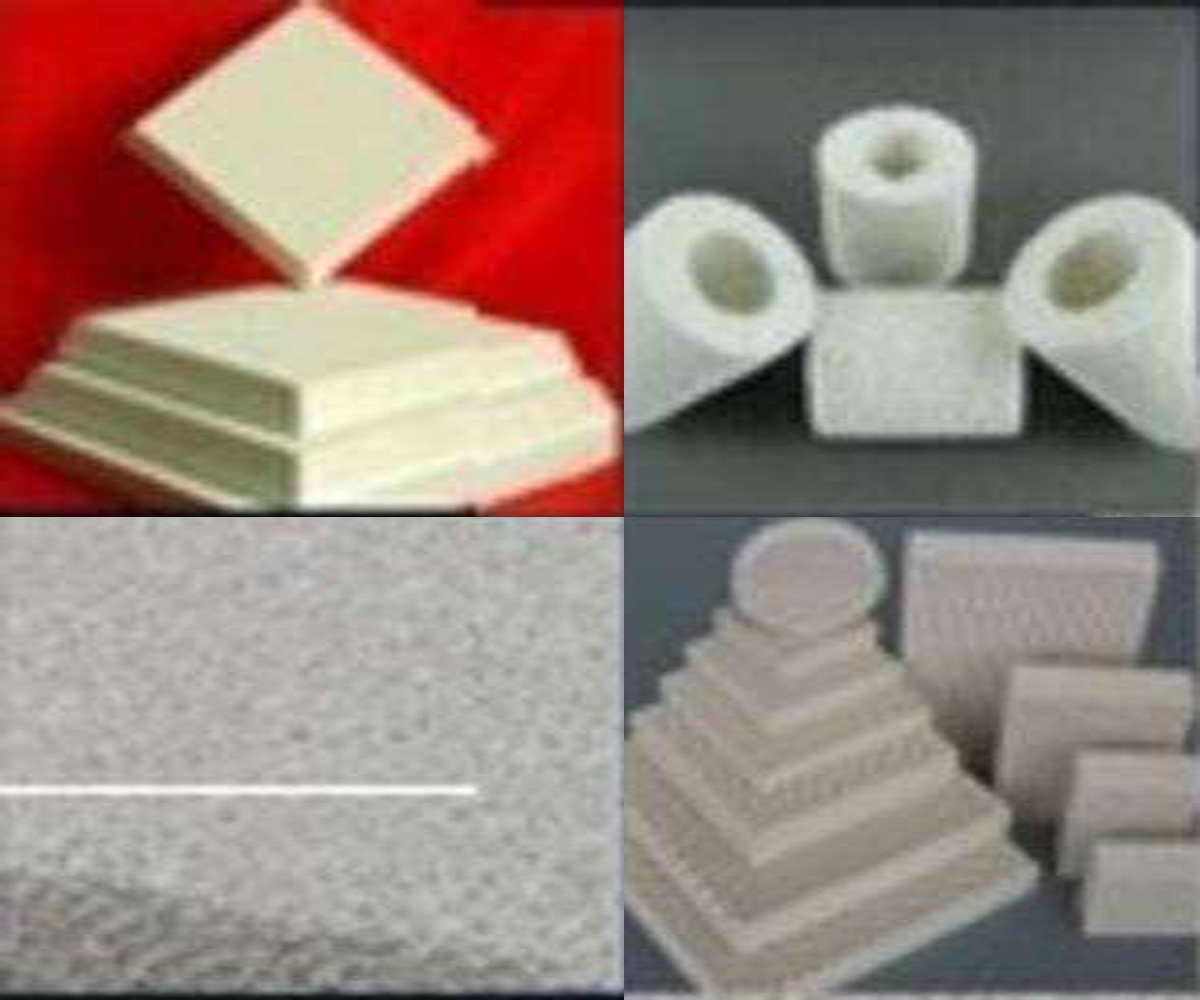

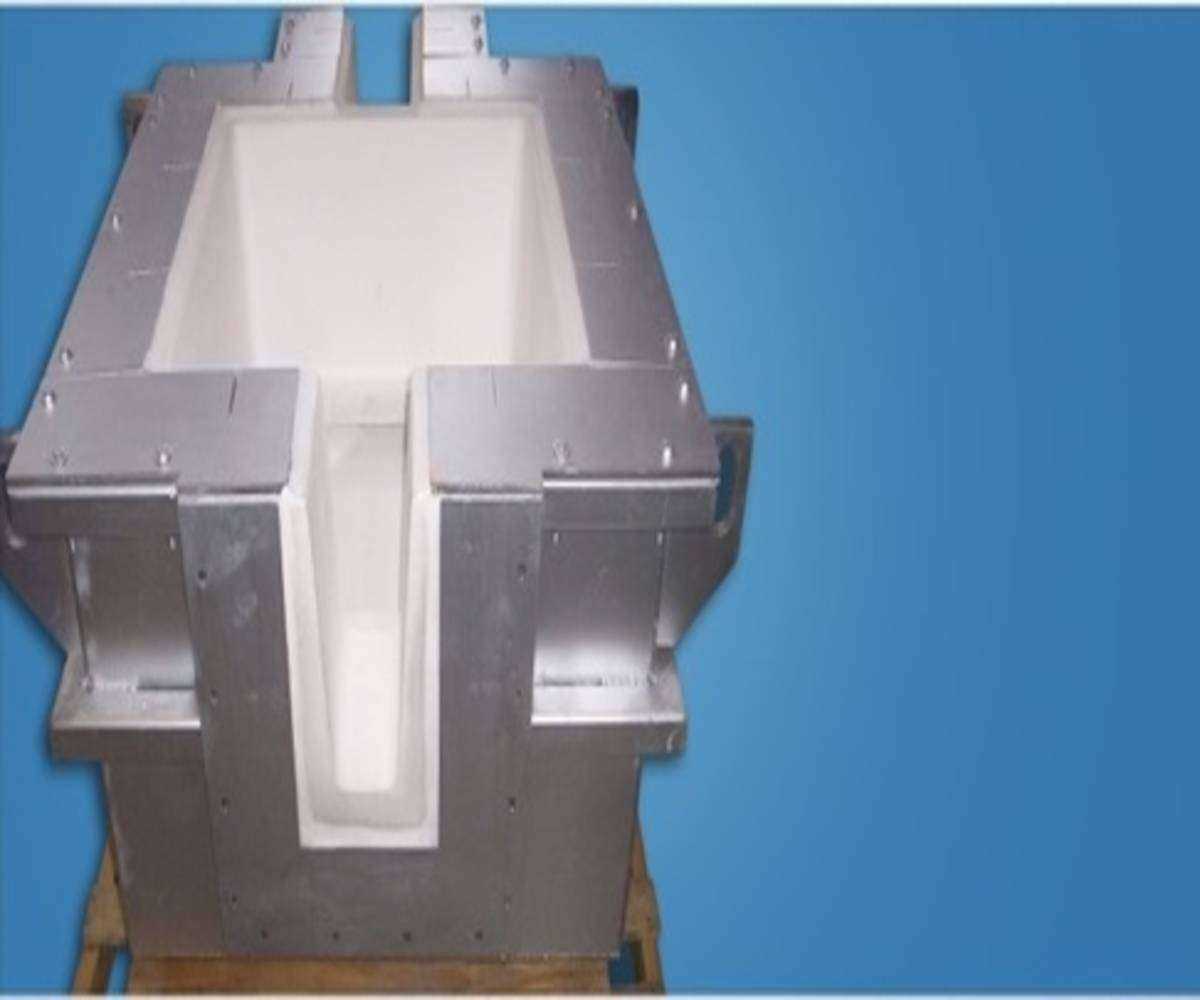

Drache's Cerapor Ceralu® Al2O3 ceramic foam filters are used in DC casting as well as continuous casting of aluminium alloys to filter and clean the molten metal. They are available with expandable or fibre gaskets and in various sizes and porosities.

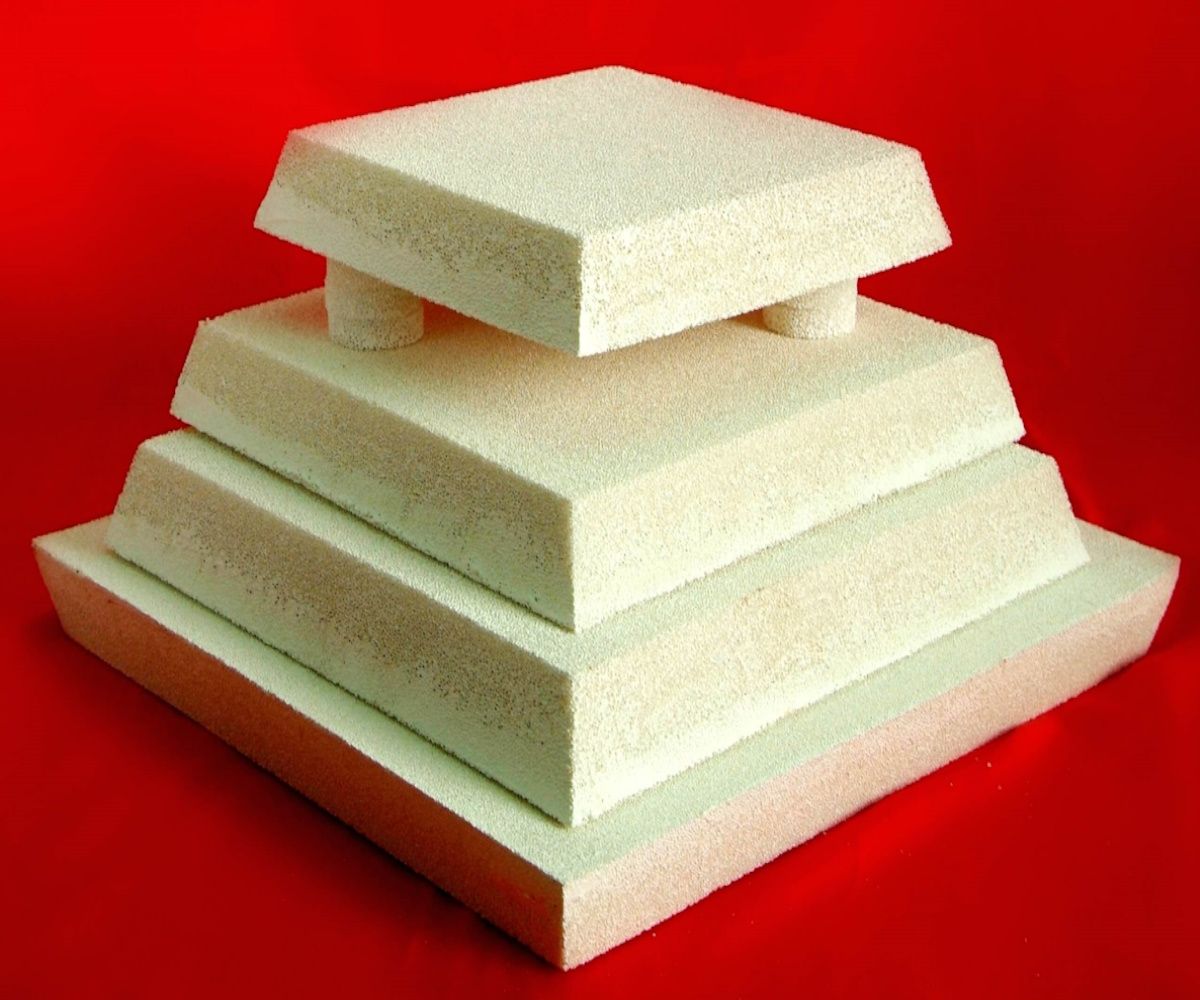

Cerapor® Ceralu® Al2O3 foam ceramic filters have been successfully used for more than three decades in continuous aluminium casting and aluminium alloy casting for filtering and purifying aluminium. They are available in two special versions. When selecting a filter, you should consider, in addition to porosity, the metal flow rate, the total tonnage cast per filter, the cleanliness of the metal upstream of the filter, the filter preheating, and its chemical composition.

Cerapor® Ceralu® Al2O3 foam ceramic filters are manufactured using certified, quality-tested processes.

Features:

| Good Chemical Resistance | : | The filters have good chemical resistance to alloying elements and foundry chemicals |

| Common Dimensions | : | The filters are available in all common standard dimensions and porosities |

| Special Dimensions | : | The filters are also available in special dimensions and designs upon request |

| For all Alloy Types | : | The filters can be used for all alloy types |

| Seal | : | The seal is applied around the edges of the filter. It prevents contact between the filter and the filter seat and ensures that no metal flows past the filter. They offer two different seal types: |

| Expanding Seal | ||

| Fiber Seal |

Other Products

You may be interested in

Post requirements