Aluminium Extrusion Press Barrel Core

By: Express Mühendislik ve Makine Sanayi Dış Tic. Ltd. Şti.| Price | Available on request |

| Category | Spare Parts |

| Manufacturer | Express Mühendislik ve Makine Sanayi Dış Tic. Ltd. Şti. |

| Min Order Quantity | 1.00 Unit |

| Delivery Lead Time | As per order |

| Place of Origin | Turkey |

| Supply Ability | Customization as required |

| Packaging Details | Standard export packing |

| Transportation Details | Road / Ship |

Description

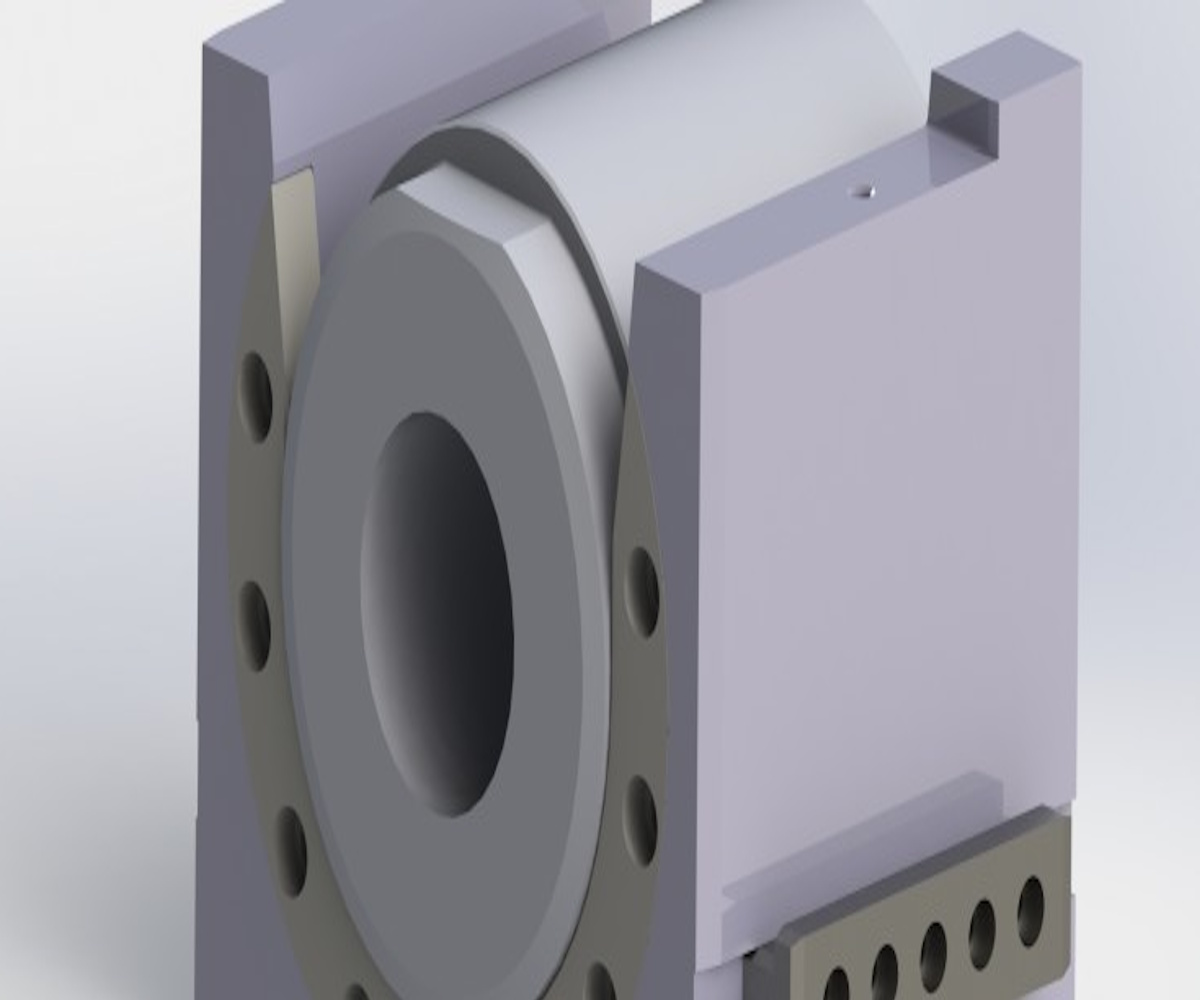

The hive group consists of the hive carrier, hive liner and hive core.

The sleeve carrier can be manufactured from welded construction, cast steel, or forged steel. Casting is the most common design, considering its cost and lifespan. The sleeve carrier provides rigid support for the sleeve. The carrier contains insulating material to prevent heat from escaping from the sleeve.

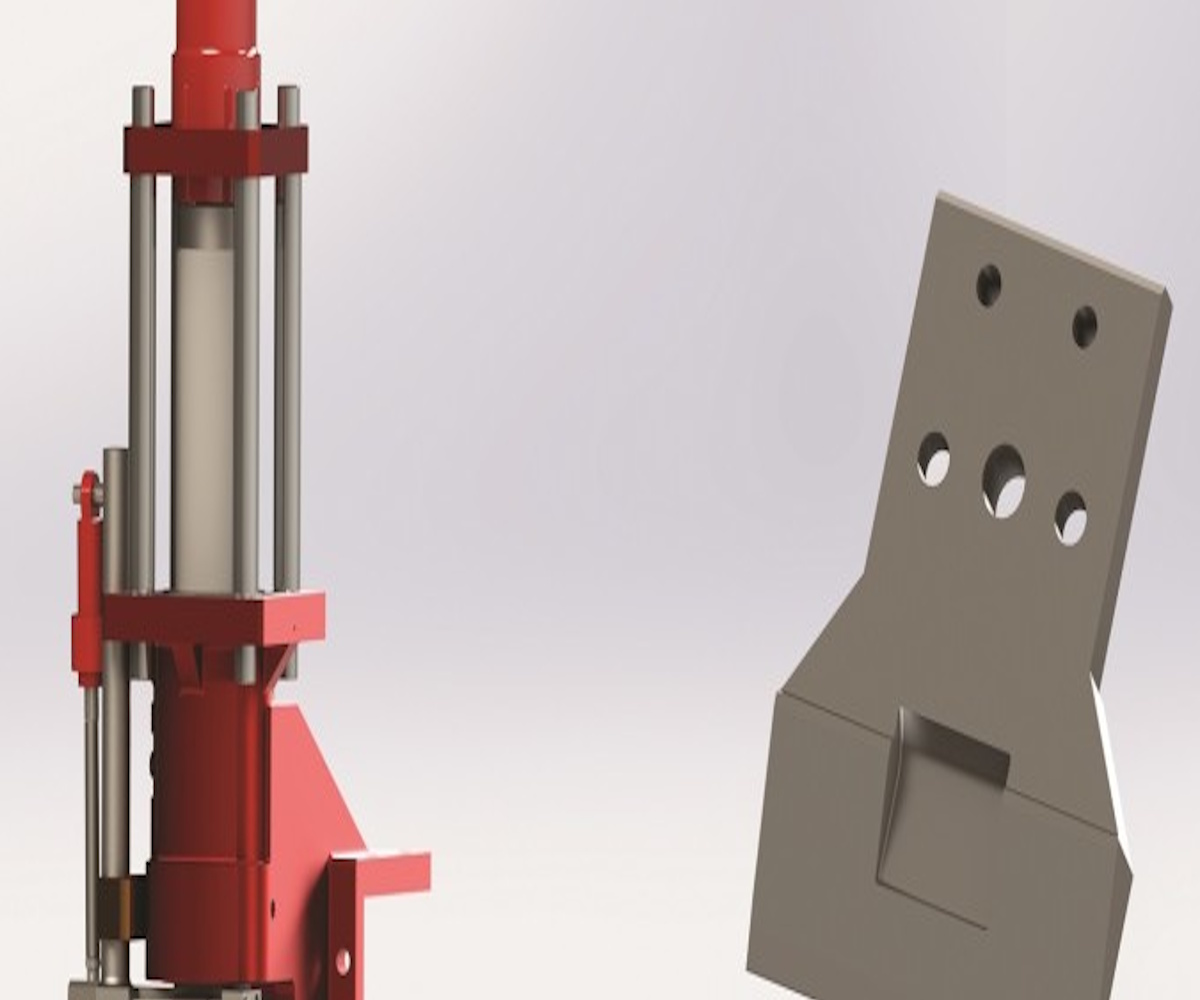

Hive systems are divided into two:

• Internally heated hive system

• Externally heated hive system

In presses with externally heated barrel systems, the heating elements are located in the barrel carrier.

In presses with internally heated barrel systems, the heating elements are located in the barrel.

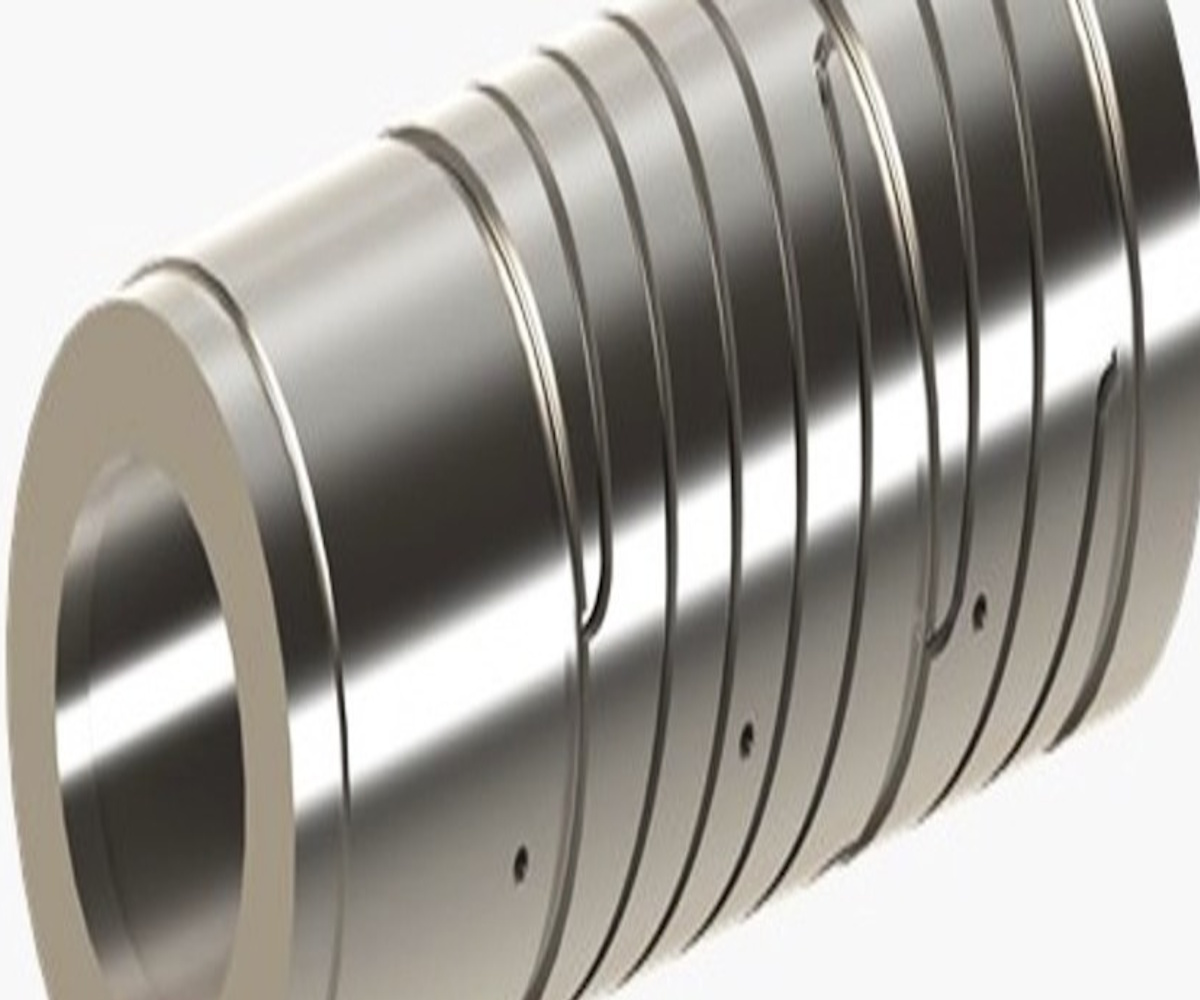

The barrel, which is exposed to very high pressures and temperatures due to operating conditions, is made of AISI H11 material. The core is mechanically driven into the barrel liner with a specific interference fit.

The core's primary function is to support the aluminium billet during printing, and the billet passes through the core during metal extrusion. Over time, the friction between the aluminium and steel at high temperatures causes deformation within the core. To minimize these deformations, the core material is selected from AISI H13 or DIN 1.2367.

Other Products

Post requirements