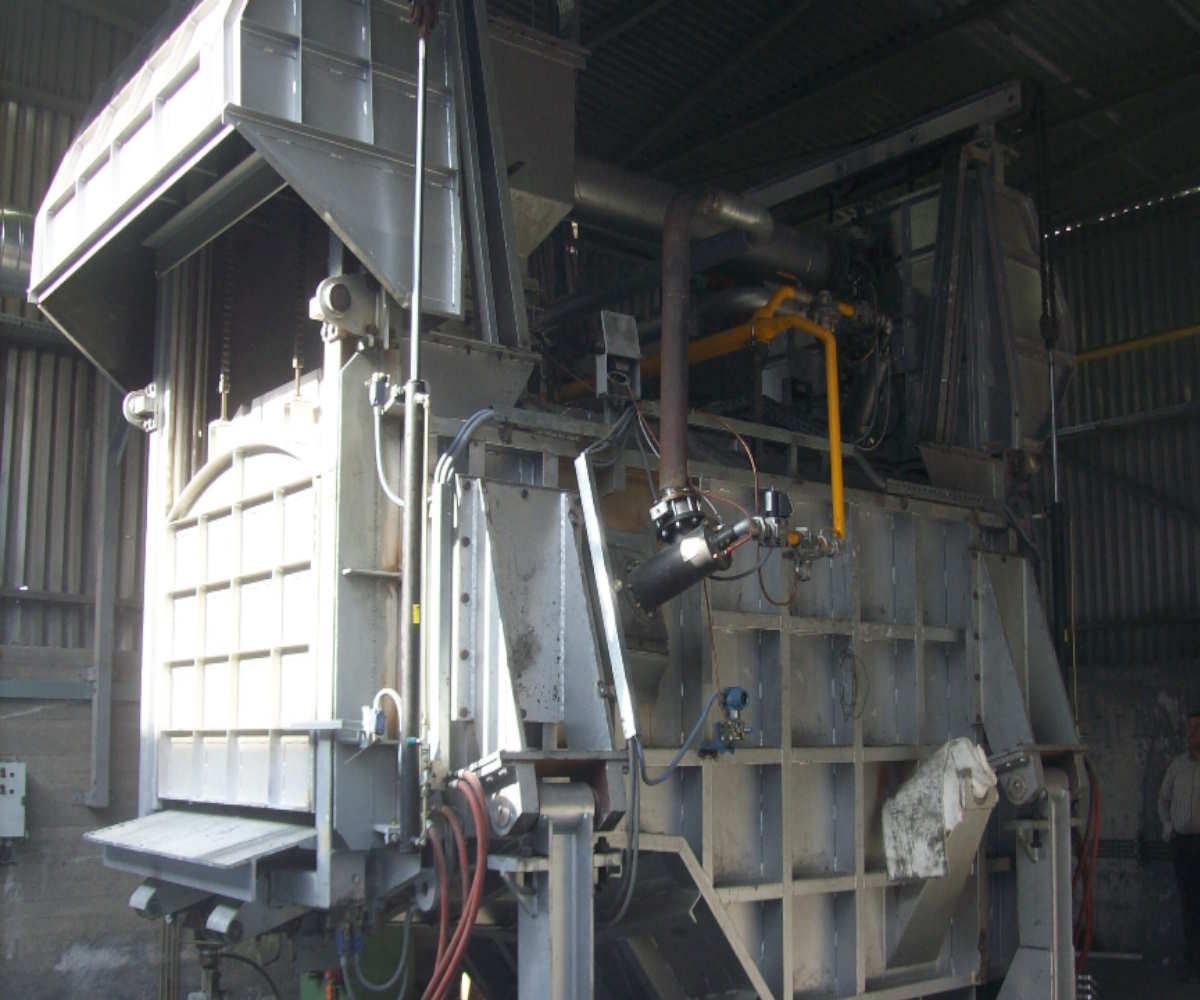

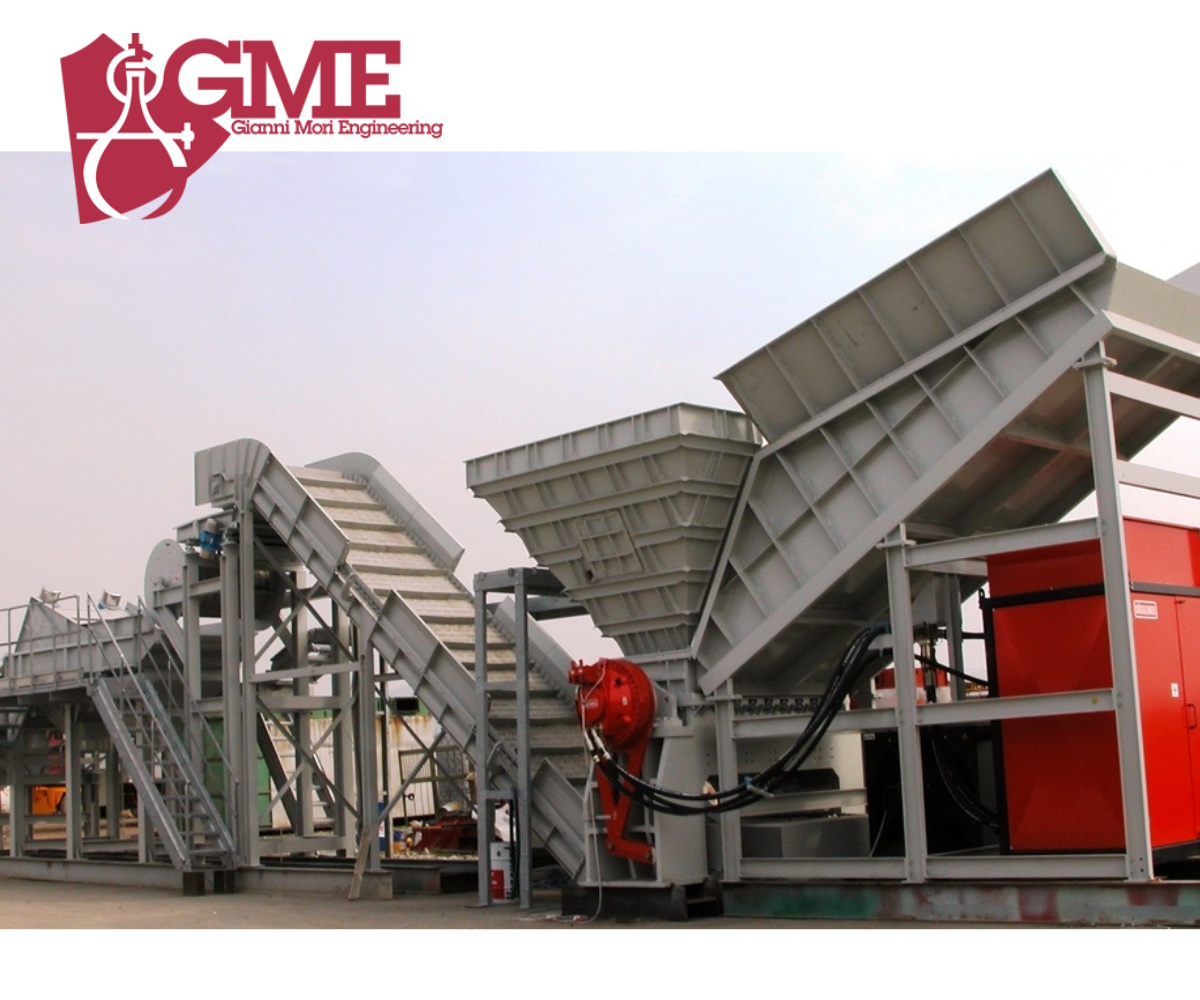

De-Coating & Delacquering Plant

By: GME Recycling| Price | Available on request |

| Category | Recycling Equipment |

| Manufacturer | GME Recycling |

| Min Order Quantity | 1.00 Unit |

| Delivery Lead Time | As per order |

| Place of Origin | Italy |

Description

De-Coating & Delacquering Plant is used for UBC (used beverage cans) or profile aluminium scrap recycling with complete removal process of grease, oil, paint, plastic.

Functions :

The Process is based on a pyrolytic system to pre-treat the scrap removing the organic part from Aluminium such as paint, oil, grease, plastic to be re-used as natural fuel for auto-thermal process, reducing.

- Natural Gas consumption both for the Decoating and Melting phase

- Dross creation

- Time To Recycle (TTR)

The core of the technology relies on a ZERO oxidation generation of the UBC (used beverage can) or profile aluminium scrap during the whole process, with tangible benefits:

- For UBC or Profile Aluminium scrap with organics over 5%, the process would not use natural gas

- For UBC or Profile Aluminium scrap with organics below 5% the standard consume of Natural gas is between 20 to 28 Nm3/ton scraps charged

- Hyper-High yield fusion of De-coated product, comparable to the melting of clean metals (bullion)

- No environmental pollution during melting process

Other Products

Post requirements