Graphite Impeller System for Treating Molten Aluminium

By: Graphite Cova GmbH| Price | Available on request |

| Category | Liquid Aluminium Handling Equipment |

| Min Order Quantity | 1.00 Unit |

| Delivery Lead Time | As per order |

| Place of Origin | Germany |

| Transportation Details | Ship |

Description

During the casting of aluminium and its alloys, it is well known that difficulties arise when dissolved hydrogen exists in the melt which leads to hydrogen gas porosity resulting in defects in the cast.

These defects greatly reduce the strength of the castings and can cause blistering during the later rolling and annealing processes.

It is common practice to treat molten aluminium with a dispersed gas such as chlorine, nitrogen or argon, or a mixture of these gases, as a method of removing the hydrogen and solid impurities.

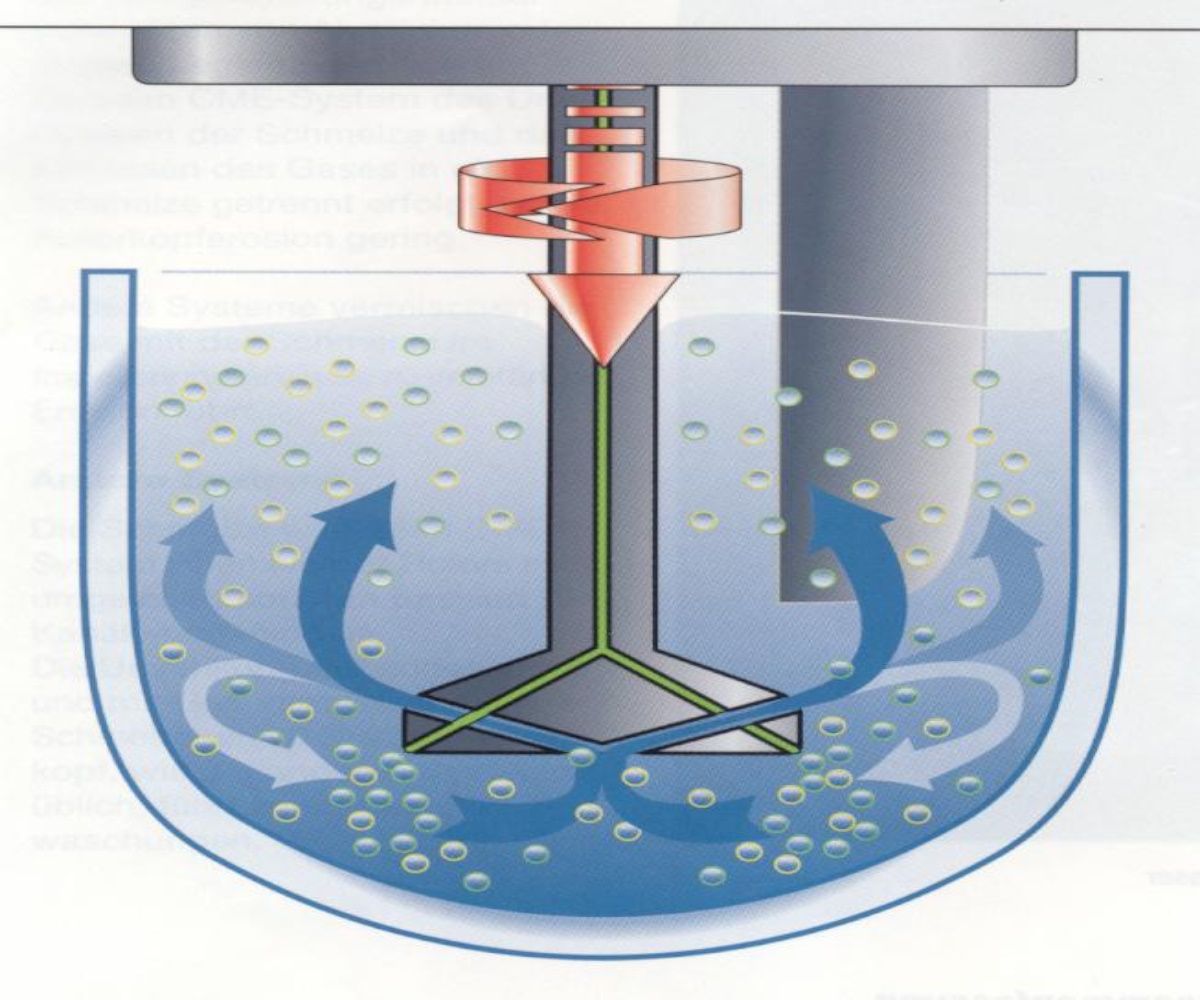

The standard practice for degassing and purification employs the use of degassing units which incorporate a shaft and rotary head which are immersed into the melt.

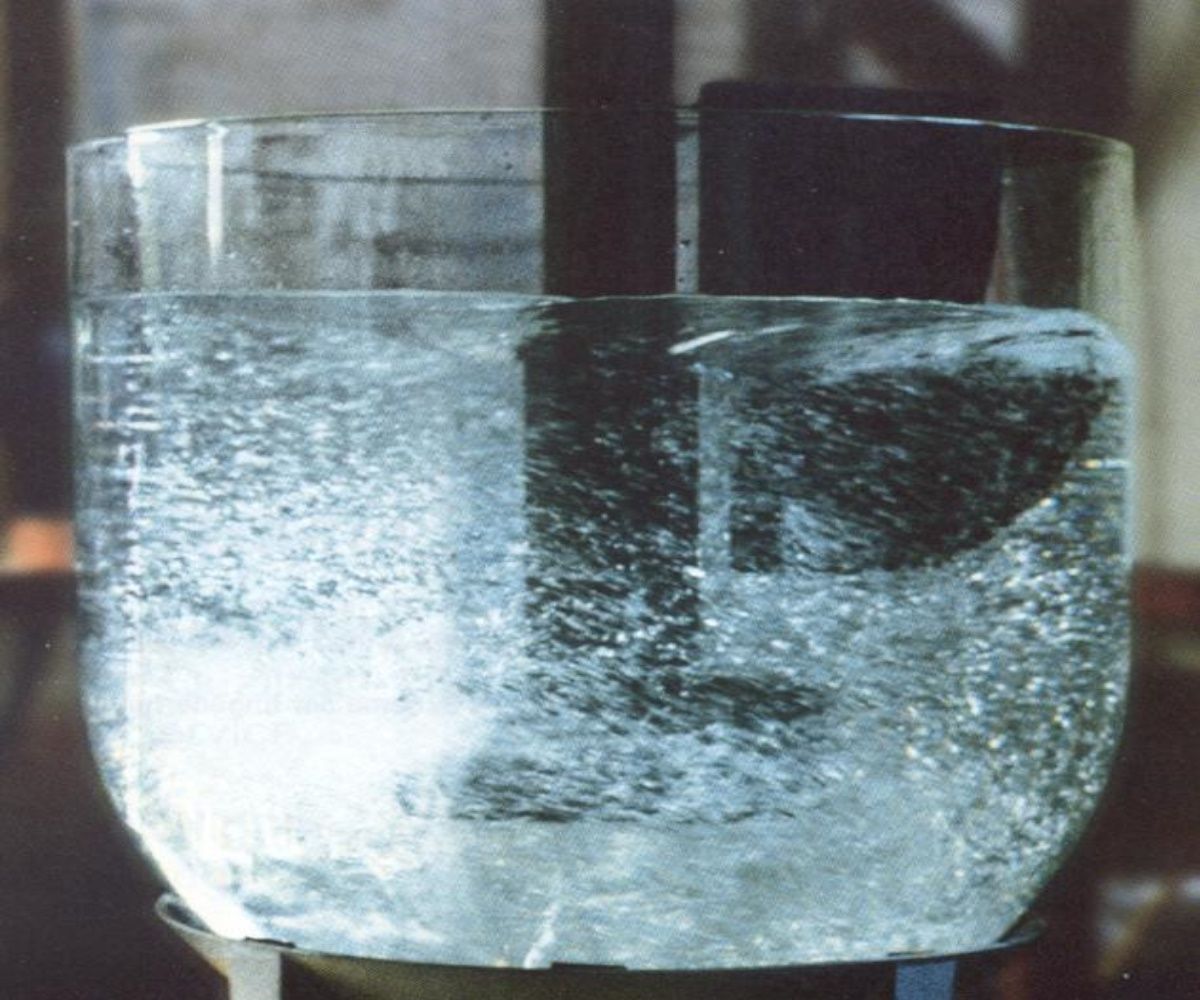

The rotary head controls the introduction and dispersion of the gas. Fine bubbles are produced and circulated in order to achieve thorough contact with the gas throughout the melt.

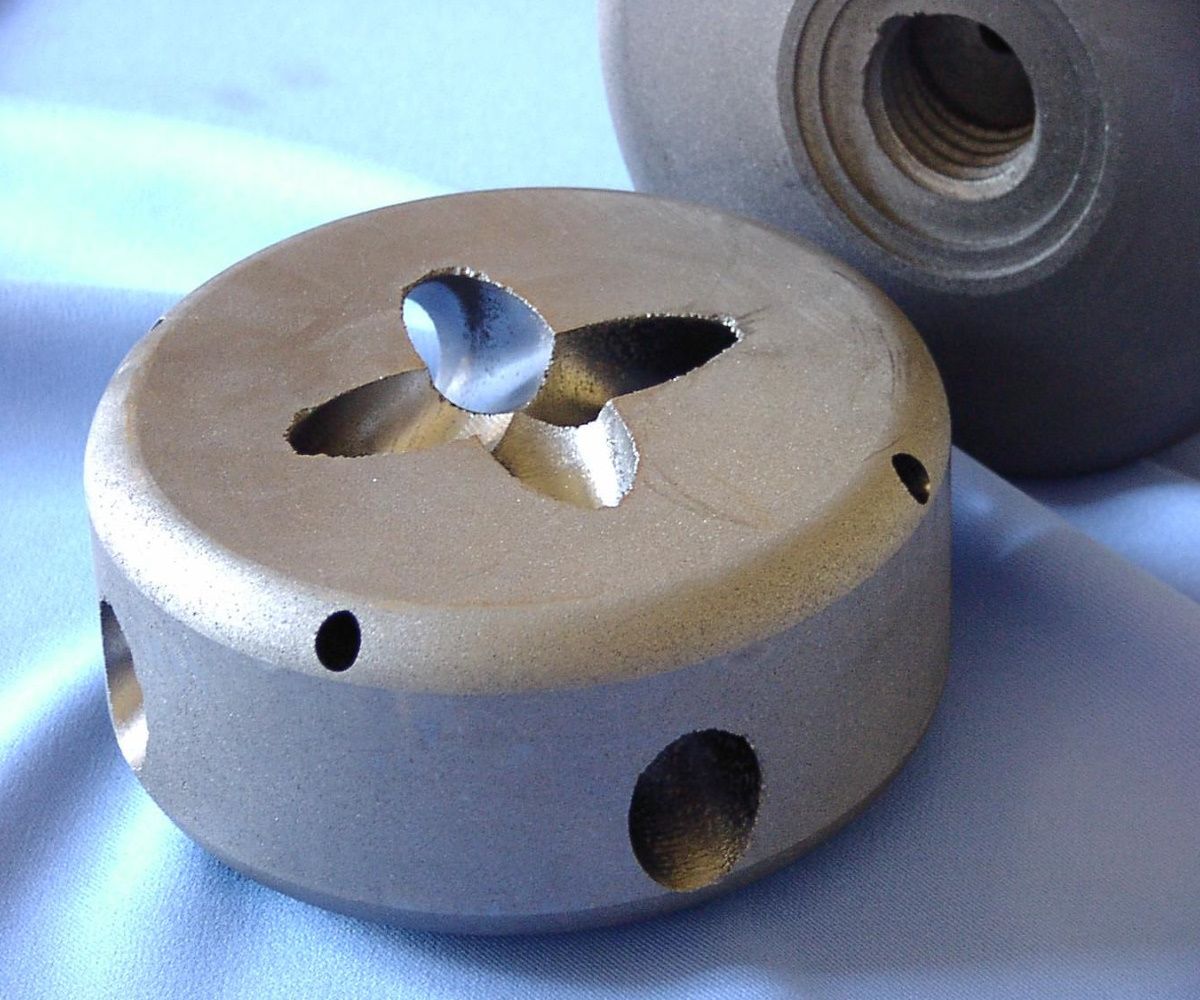

The rotary device, developed by Graphite COVA GmbH, consists of a hollow rotary shaft and a rotating pump head which is attached to the shaft.

The pump head contains four or more channels rising from the bottom centre to the outer shell of the rotor, which pumps and circulates the melt, and four or more jet holes which inject the gas.

These jet holes are connected to the hollow shaft and are slanted down to the surface of the rotor head.

The rotor head is most often connected to the shaft by a cylindrical nipple, although other connection designs are available upon request.

Other Products

Post requirements