Description

CNC Roll Bending Machine for windows and doors metal profile bending, also the Pipe Tube Section Angle Bar, Contact us to get the best price.

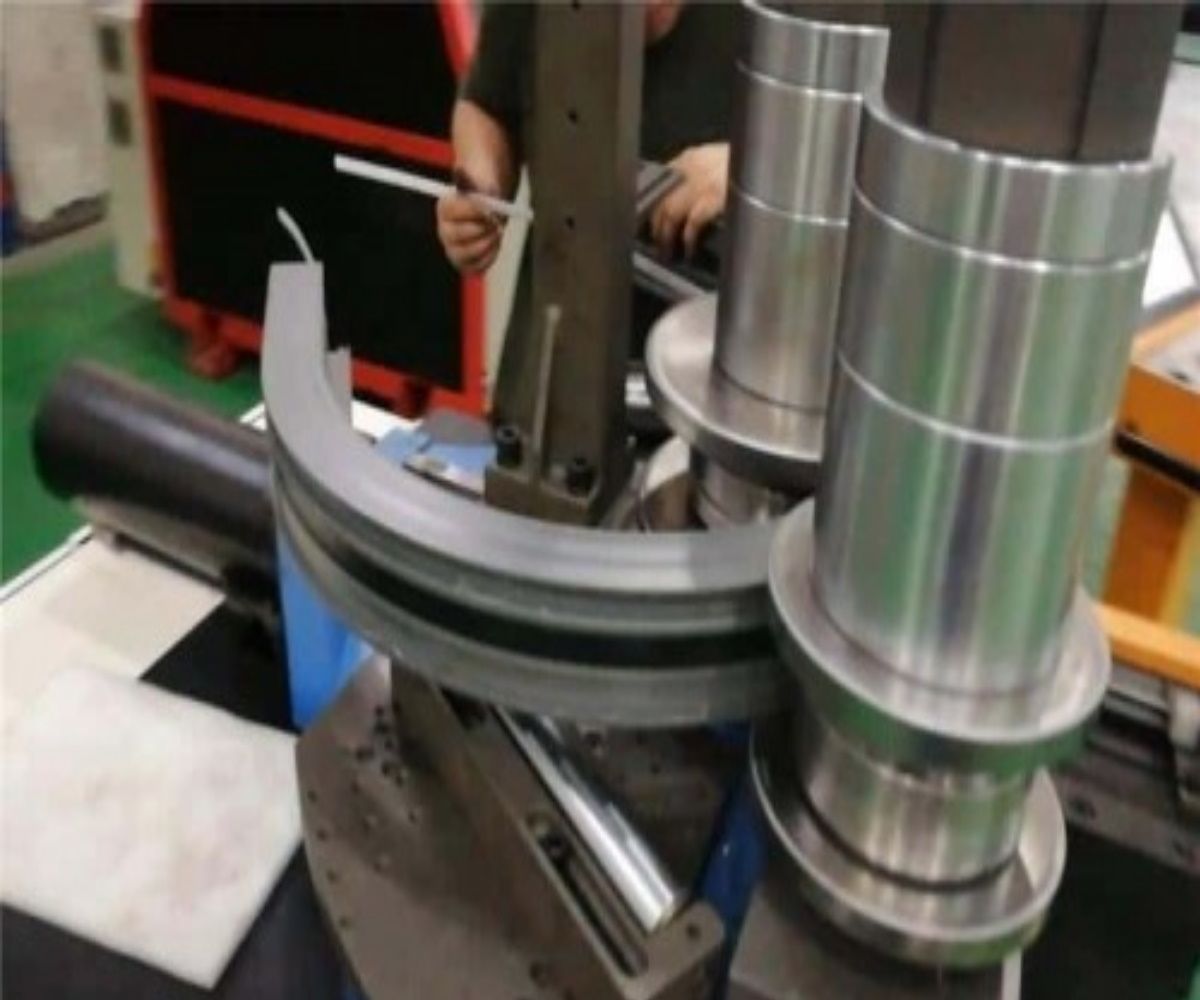

Roll Bending Machine G-CNC-B25T is Automatic CNC control, for example, it adopts servo technique, rational design and CNC control system. Therefore, It represents the perfect combination of machinery, electronic and hydraulic design.

The B-type series CNC Roll Bending Machine is suitable to large material, for example, the Windows and Doors profile. For example, every individual roller drive by our unique servo hydraulic system. The G Clef bending machine has been recognized by more and more customers in China with its unique skilled technology, that is to say, know-how experience.

G Clef is able to curve extruded and brake-formed profiles in Aluminum, steel, stainless steel, brass, bronze, and other exotic metals.G Clef will provide customized tooling design services accordingly, by providing various methods for bending depends on higher rotation speeds with full drive torque throughout the speed range.

Machine Features

Advanced measurement function for material spring back, CNC data will be automatically updated according to the measurement result,thus no more negative influence from material spring back.

With the servo hydraulic system, in short the benefits are as follow:

1.Stable , as well as controllable hydraulic pressure in the whole bending process.

2.Because the Overflow valve working time is shorten, and the oil temperature is dropped, thus it completely solving the oil temperature problems caused by Summer, in turn it will absolutely increase accuracy.

3.High electricity usage efficiency, as well as Reducing sound pollution.

4.Three independent rollers, stepless speed regulation, rollers’ speed auto matching, thus difference between roller linear speeds (Outer and inner radius) can be offset, and no more scratch marks on appearance.

Roll Bending Machine Advantages

Firstly, Automatic CNC bending systems, just input your profile dwg or CAD drawing to our machine, as a result, there’s no need to reply on experienced workers. The system is Easy to learn and Easy to operate, therefore it only need 1-2 days, then any fresh man can easily understand the program.

Secondly, High push force, high accuracy hydraulic close-loop control system, repeatability positioning accuracy reach 0.01mm.

Thirdly, Anyone can operate, high-precision and repeat production, regardless of people Motion control, bending algorithm, low energy consumption Hydraulic control 0.01mm, cnc system, automatic generation of running program

Fourthly, Less than 5 materials, theoretical digital approach.

Finally, Applications includes Aerospace, new energy vehicles, rail transit, escalators, wind power nuclear energy.

Bending: Backrest Frame for Reference

major axis=600mm Minor axis=400mm

Material: wild steel

Profile: 10 x 30mm,1.5mm thick, one joint only