Section Bending Machine A12T | Section Bender

By: Guangdong G Clef Bending Technology Co. Ltd| Price | Available on request |

| Category | Equipment |

| Manufacturer | Guangdong G Clef Bending Technology Co. Ltd |

| Min Order Quantity | 1.00 Unit |

| Delivery Lead Time | As per Order |

| Place of Origin | China |

| Supply Ability | Customization on Requirement |

| Packaging Details | Standard Export Packing |

| Transportation Details | Road/Ship |

Description

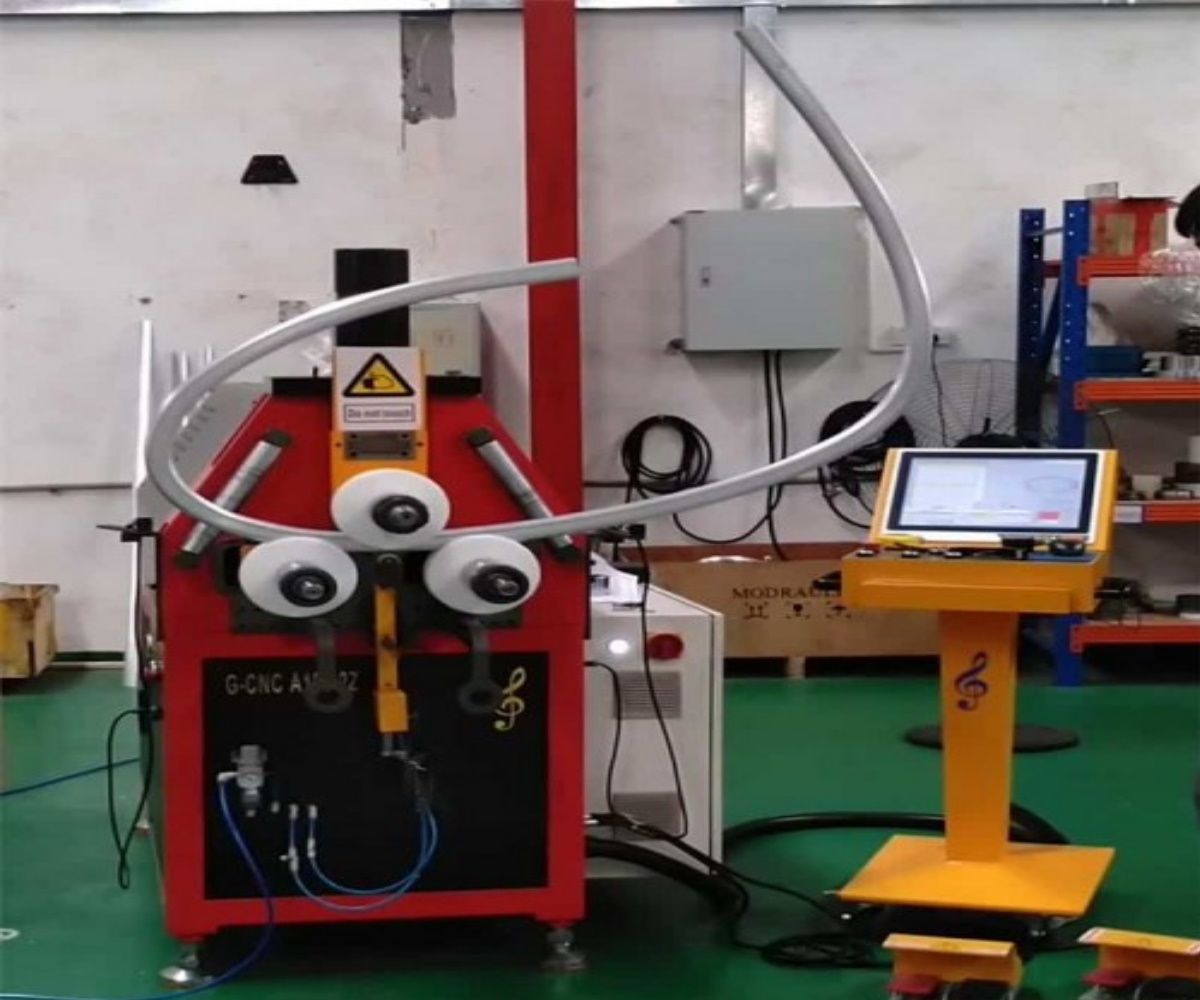

CNC Section bending machine | section bender uses multiple servo motors, computer operating systems, reducers, and sensors are all well-known brands.

Section Bending Machine with high push force, high accuracy hydraulic close-loop control system, as a result, repeatability positioning accuracy reach 0.01mm.

- Servo pump technology, reduce a lot hydraulic heating problem, improve saving energy ability significantly

- We own completely self-made software system patent, thus no worry of any restriction from a third party.

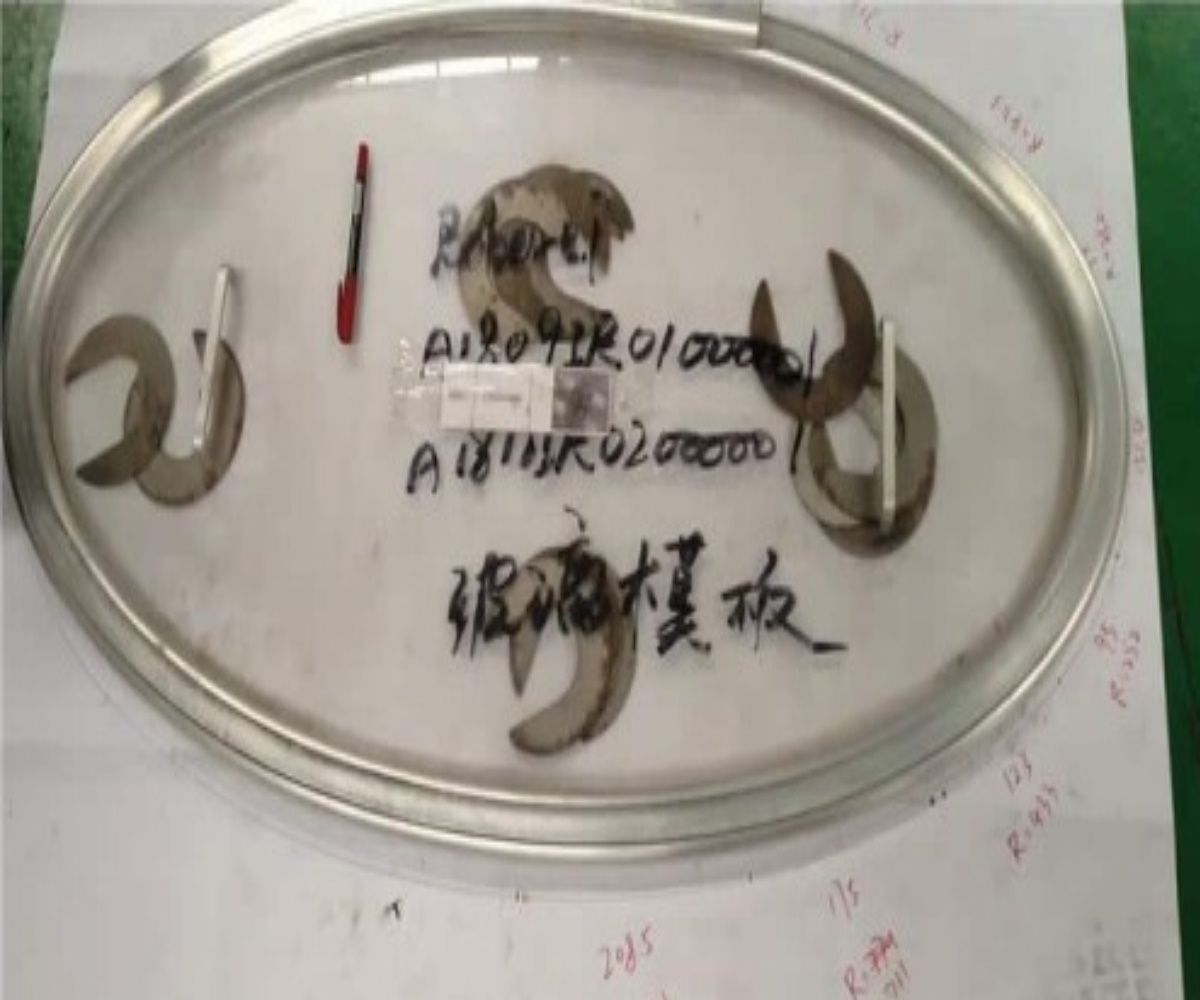

- Cold forming equipment: in the natural case where the material is not heated, the product is processed into a contour matching the pattern according to a given pattern.

Section Bending Machine | section bender Benefits

3 rollers confirms the shape, as a result it can automatically bend the shape according to your input CAD drawing. 3 Rollers are individually drive by servo motor and controlled by position mode but not speed.

The unique program can help you make consistent ellipse, spline, as well as spiral in mass production. That is to say, the machine has greatly improved the precision and performance, and the machine has the advantages of fast production speed, good stability, durability, low failure rate, fast speed adjustment, it will make your bending simple.

The minimum process for one-time bending or new workpieces with good quality reduces the waste of materials, firstly, reduces the dependence of the personnel experience, secondly, reduces the operation rate, thirdly,reduces the production cost, finally, shortens the production cycle and reduces the inventory .

G Clef Bending Introduction

As a leading roll bending & stretch forming & stretch bending machine manufacturer in China since 2012, G Clef bending machine could bend profile, tube, pipe, stainless steel, aluminum, section into 2D or 3D with high precision by CNC.

No files available!!

Post requirements