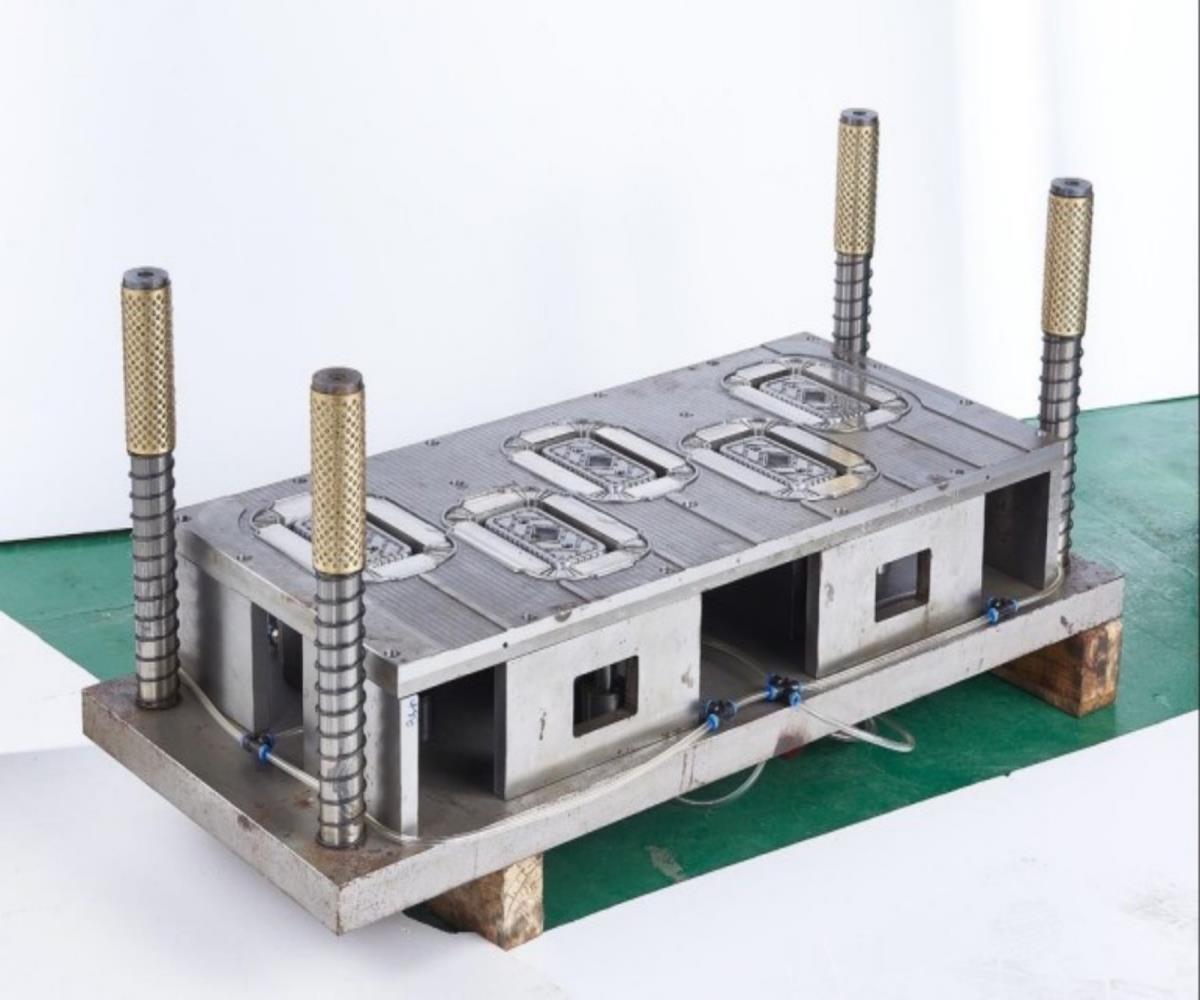

Two Cavity Aluminum Foil Container Mould

By: Guangzhou KONIX Machinery Co.,Ltd| Material | D2,D3, DC53 |

| Category | Aluminium Consumer Goods Equipment |

| Manufacturer | Guangzhou KONIX Machinery |

| Min Order Quantity | 1.00 Unit |

| Delivery Lead Time | 1 |

| Price | 1.00 |

| Place of Origin | 1 |

| Supply Ability | 1 |

| Packaging Details | 1 |

| Transportation Details | 1 |

Description

With the flexibility of gas, it adopts the principle of gas compression and rebound, high precision, more stable.

Manufactured with best heat treatment and WEDM-LS process, with high processing accuracy within 0.005mm.

The processing of aluminum foil containers is completed from cutting, stretching, forming, curling, and finished products at one time, including various sides (G side, L side or IVC, folding side, etc.).

The normal service life of the mold: 10 million to 100 million times (excluding wearing parts) the wearing parts are shears, guide pillars, cylinders, crimping grooves, etc.

Mold materials and processing technology: mainly 45 carbon steel, DC53, CR12MOV, after quenching and tempering, vacuum heat and deepening cold treatment, etc., the mold is equipped with precision guide posts and guide bushes, slow wire cutting processing, precision surface grinding, and all accessories are Fine workmanship.

Mold size: depends on container size and number of cavities

Mold speed: 60 times/minute

Other Products

Post requirements