Aluminium Billet

By: Haspolat Alüminyum San. ve Tic. A.Ş.| Price | Available on request |

| Category | Aluminium Billet |

| Manufacturer | Haspolat Alüminyum San. ve Tic. A.Ş. |

| Min Order Quantity | 10.00 MT |

| Delivery Lead Time | As per order |

| Place of Origin | Turkey |

| Supply Ability | Customization as required |

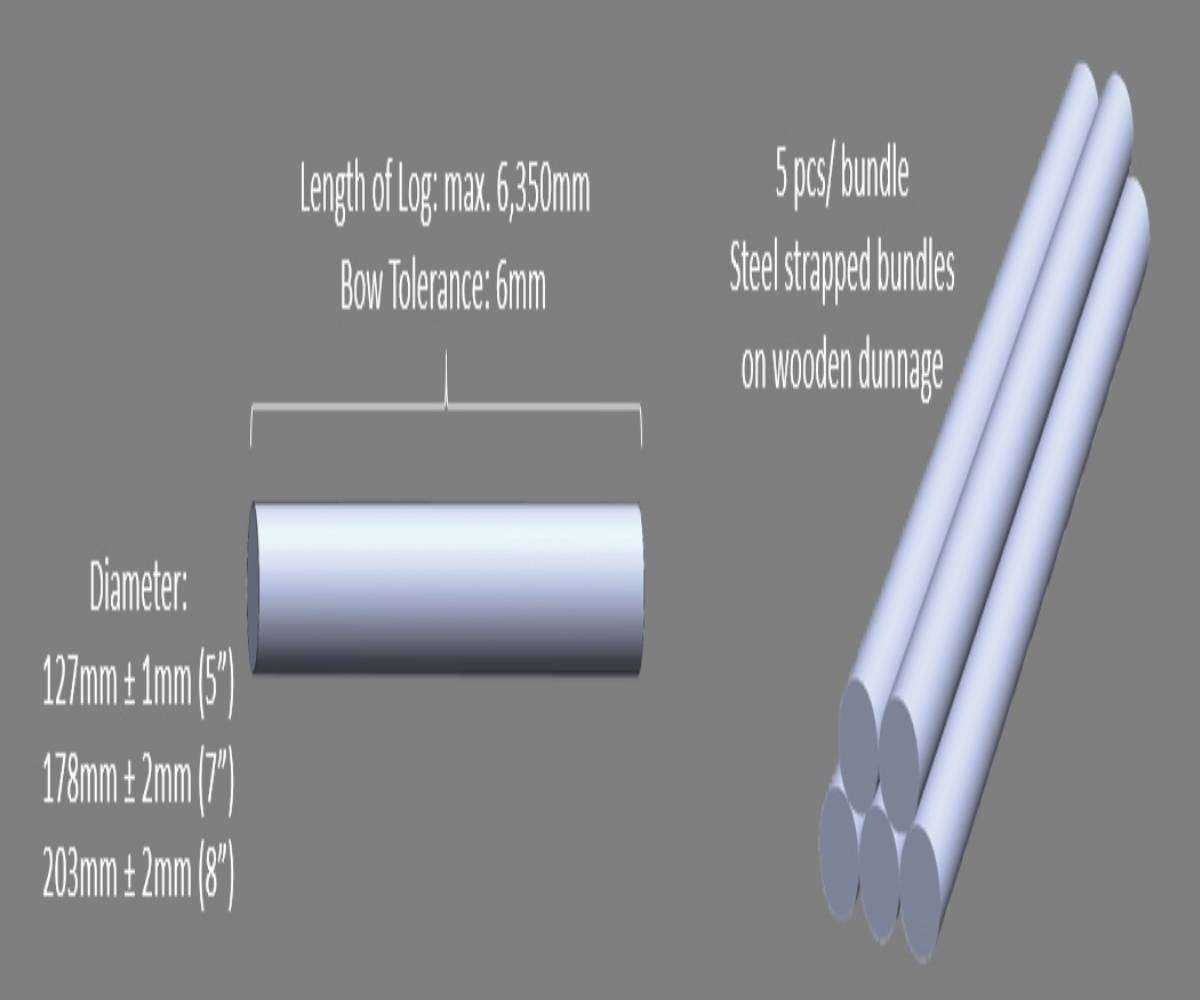

| Packaging Details | Standard export packing |

| Transportation Details | Road / Ship |

Description

An aluminium billet is a small, semi-finished piece of metal, usually rectangular, circular or square in shape. It is a semi-finished casting that requires further processing before becoming a finished product.

FEATURES OF ALUMINUM BILLETS:

When producing billets from aluminium scrap or aluminium shavings using the melting method, the most important factor is that the molten aluminium contains very little or no iron. A high iron content during alumiuim profile extrusion can create marks in the extrusion, which is undesirable. The aluminium shavings are heated to 700 degrees Celsius to purify them. The furnace temperature during this time can reach 1000 degrees Celsius.

Molten aluminium is poured from the furnace into crucibles. The crucibles must be completely free of water during this process, as water can cause an explosion when it comes into contact with the hot aluminum. Many people have been injured in this way.

The aluminium poured into the crucibles for billet production is cooled by operating the cooling system and then removed from the crucibles.

Due to the constant cross-sectional shape and length of aluminium billets, the most suitable process for obtaining the product is extrusion. The alloys used for the production of aluminium profiles by the extrusion process are from the wrought alloys group.

6000 Series Alloys:

Profiles manufactured for architectural purposes are generally produced from 6000 alloys by extrusion. As mentioned above, the AA 6000 series alloys contain magnesium (Mg) and silicon (Si). The proportions of other impurities (such as Fe, Cu, Mn and Zn) along with Mg and Si impart different properties to the alloys. For example, 6000 alloys with an iron (Fe) content of 0.20% or less are more suitable for achieving a glossy surface. Higher iron content should be preferred for a matte finish.

Among the 6000 series (AlMgSi) alloys, the most commonly used in the architectural and construction industries are 6060 and 6063 (in EN and the new TS notation) and AlMgSi0.5 (in DIN and the old TS notation). Their chemical compositions are generally the same, but they exhibit nuanced differences in the lower and upper limits.

6005 / 6005A:

EN AW / AA 6005, 6005A alloys, when compared to 6063, are harder, have stronger mechanical properties but are more expensive and more difficult to extrude, thus making the production of complex geometries difficult or hindering.

Profiles made of 6005A alloy can be anodized for protection, but the surface quality makes it difficult to obtain a decorative appearance.

In terms of plastic forming ability, this alloy is not as successful as 6063.

6060:

This alloy is suitable for optimal surface quality when strength is not the most important criterion. It is preferred for decorative purposes such as furniture profiles.

6063:

Application areas: Architectural sections in window, door and facade systems, furnishings, frame systems, lighting, steps, rails, electronic modules, electric motor frames, fasteners, coolers, radiators, pneumatics, irrigation and furniture profiles. 6063 is slightly harder than 6060 but less extrudable.

Characteristic features: high corrosion resistance, very good weldability, high fatigue resistance, cold forming and can be shaped into complex geometries.

6082:

Compared to 6005, it has slightly better impact toughness but a slightly lower susceptibility to decorative anodizing. Other properties are similar to those of alloys 6005 and 6005A. To reiterate.

Compared to 6063, the EN AW/AA 6082 alloy is harder, has stronger mechanical properties but is more expensive and more difficult to extrude, making the production of complex geometries difficult or hindering.

Profiles made of 6082 alloy can be anodized for protection, but the surface quality makes it difficult to obtain a decorative appearance.

In terms of plastic forming ability, this alloy is not as successful as 6063.

Application areas: Heavy structures in railway wagons, truck guardrails, shipbuilding industry, bridges, bicycles, boilers, platforms, flanges, hydraulic parts, pylons, ship masts, awning pipes, rivets

Characteristic features: High corrosion resistance, very good weldability, suitable for machine construction, very good cold forming quality in stabilized form after T4 heat treatment, moderate fatigue strength, not suitable for complex parts.

6101:

Alloy 6101 may be suitable for profiles with high electrical conductivity and high hardness. The 1000 series alloys also have high electrical conductivity, but 6101 is better for cutting and machining and its tensile strength is also better than the 1000 series.

6463:

It is the most suitable alloy for obtaining bright aluminium.

Other Products

You may be interested in

Post requirements