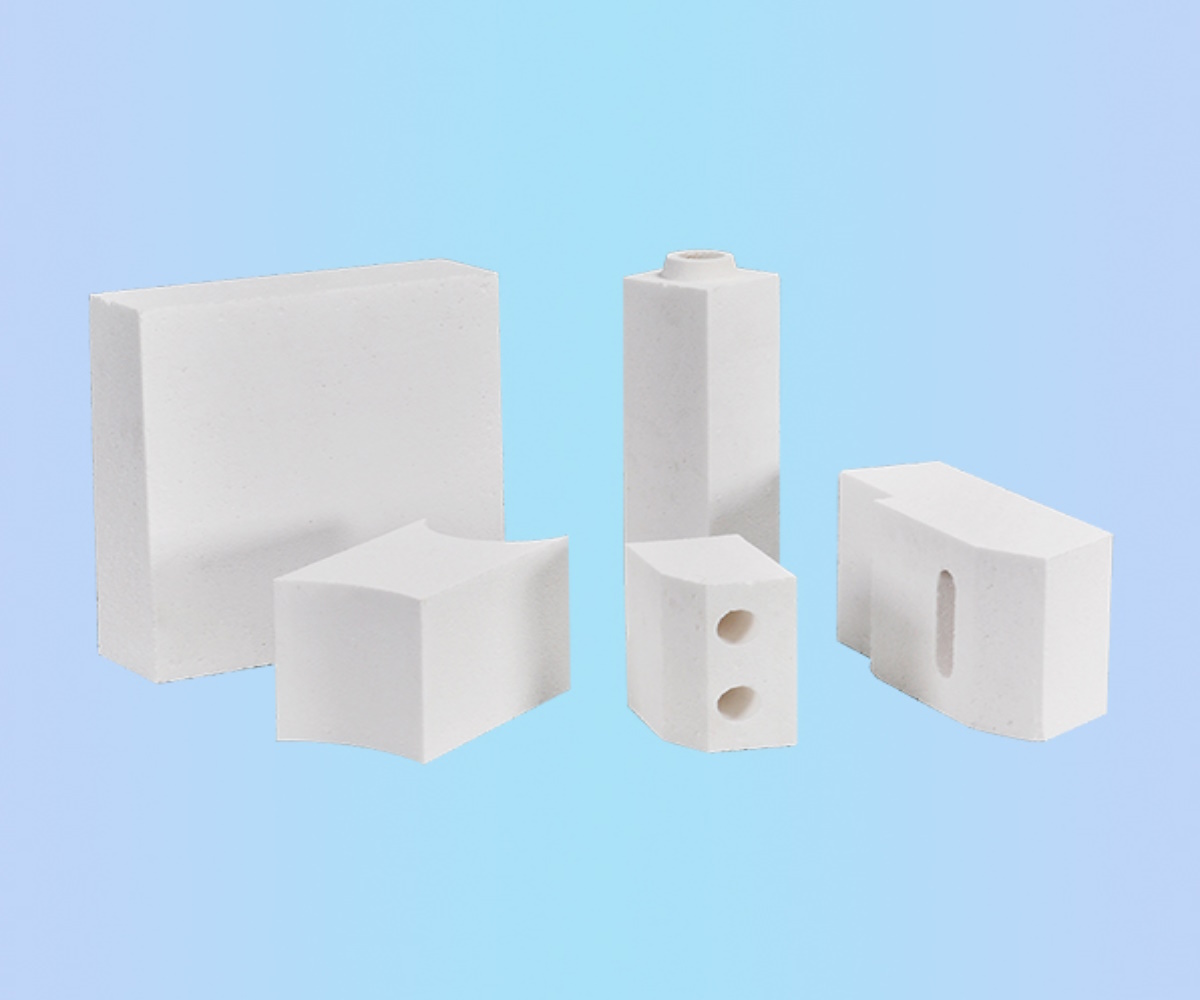

Phosphate Bonded High Alumina Bricks

By: Henan Hongtai Kiln Refractory Co.Ltd| Price | Available on request |

| Category | Refractory Bricks |

| Min Order Quantity | 10.00 MT |

| Delivery Lead Time | As per order |

| Place of Origin | China |

| Supply Ability | Customization as required |

| Packaging Details | Standard export packing |

| Transportation Details | Ship |

Description

Phosphate bonded high alumina bricks are made of dense special grade or first grade high alumina bauxite clinker as the main raw material, phosphoric acid solution or aluminum phosphate solution as the binder, after semi-dry press molding, heat treatment at 400~600℃ Into chemically bonded refractory products. It is a non-burning brick. In order to avoid the large shrinkage of the product during high temperature use, it is generally necessary to introduce heat-expandable raw materials, such as kyanite, sillimanite, pyrophyllite, silica, etc., into the ingredients. Compared with ceramic-bonded fired high alumina bricks, its resistance to peeling is better, but its load softening temperature is lower, and its corrosion resistance is poor. Therefore, a small amount of fused corundum, mullite, etc. needs to be added to strengthen the matrix. . Phosphate bonded high alumina bricks are suitable for cement kilns, electric furnace tops, and ladle.

Phosphate high alumina bricks are made of high-quality high alumina bauxite as raw materials, combined with aluminum dihydrogen phosphate, and dried in a drying oven. Phosphate high alumina bricks are mainly used in dry-process cement production kilns, rotary kilns, phosphorous chemical kilns, etc. Phosphate high alumina bricks have high refractoriness, good wear resistance and high strength.

Other Products

Post requirements