Aluminium Coil Grade 1100

By: Henan Mingtai Aluminum Co. Ltd| Price | Available on request |

| Category | Building and Construction Coil |

| Manufacturer | Mingtai Aluminum |

| Min Order Quantity | 10.00 MT |

| Delivery Lead Time | 30 Days |

| Place of Origin | China |

| Supply Ability | Customization on Requirement |

| Packaging Details | As per customer's specification |

| Transportation Details | Road / Ship |

Description

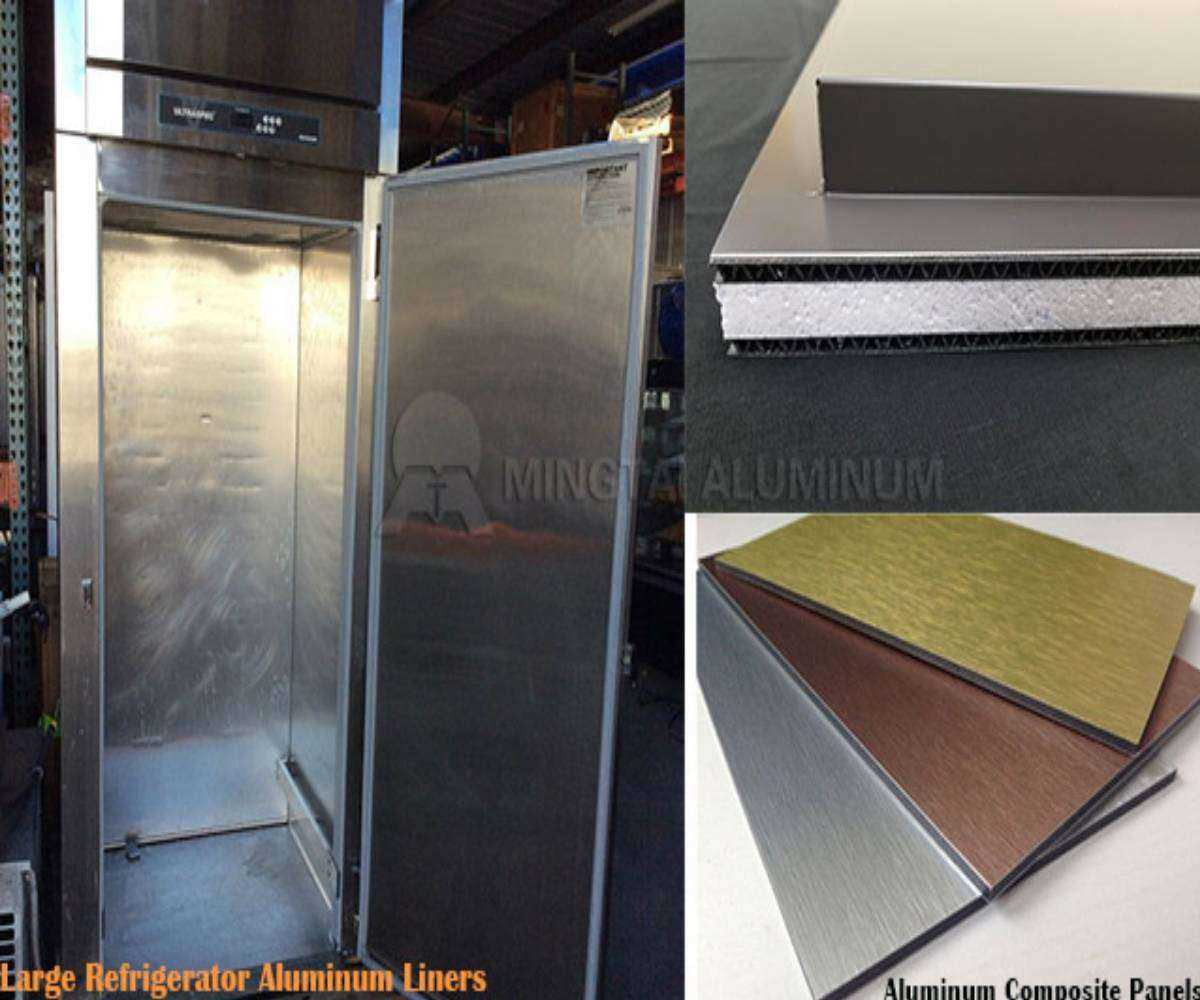

1100 aluminum coil, containing at least 99% Al, is the most heavily alloyed of the 1000 series, so becomes the mechanically strongest alloy in this series. Similarly, 1100 aluminium alloy coil shows the properties of other 1 series alloy that is close to pure aluminum. Such as excellent ductility,processability, corrosion resistance, weldability, surface handling, conductivity and heat transfer. Due to its excellent processability, 1100 aluminum coil can be well adapted to applications that are difficult to form. Therefore, 1100 aluminium alloy coil is often used as large refrigerator aluminum liners, HVAC, aluminum composite panels, building decoration, deep stamping parts, sheet metal processing workpiece, nameplate, etc.

Applications and Features:

1. Strong Corrosion Resistance. 1100 aluminum coil is highly resistant to corrosion by water and atmosphere. Besides, under 0℃, its strength will increase, and low temperature brittleness won’t occur.

2.Excellent Weldability. It is worth mentioning that 1100 aluminium alloy coil can be welded by any method.

3.Mechanical Properties. 1100-h14 aluminum coil tensile strength σb (MPa) is 125, yield strengthσ0.2 (MPa) is 115, elongationδ16 (%) is 10, and HB is 32. Here, the thickness tolerance of Mingtai 1100 aluminum coil can be (-0,02/+0mm).

Uses of 1100 Aluminum Coil:

1.1100 H16 Aluminium Coils for Aluminum Composite Panels

2.Aluminum composite panel, also known as aluminous model board, is composed of multi-layer materials, the upper and lower layers are high purity aluminum alloy panels, while the middle is compound composite materials, such as PE as the core board. Aluminum composite panels perfectly combine the advantages of alloy Al and nonmetal. In Mingtai Al, a customer from Turkey purchased 150 tons of mill finish 1100 aluminum coil for ACP from us ! The thickness of the procurement requirements of 0.12 mm, 0.15 mm, 0.18 mm, 0.24 mm, the thickness tolerance in (-0,02/+0mm), etc.

3.Other Usages

Besides, 0.35mm 1100-H16 aluminum coil for large refrigerator aluminum liners also has very high practicality. In practice, 1100 aluminum coil also has been widely applied in HVAC,condenser, radiator, evaporator, deep stamping parts, sheet metal processing workpiece, nameplate, fan blades, spinning, chemical instruments, transportation equipment components, etc.

Other Products

Post requirements