Aluminium Vacuum Brazing Furnaces

By: Inductotherm Group Türkiye| Price | Available on request |

| Category | Heat Treatment Furnace |

| Manufacturer | Inductotherm Induction Systems Industry Inc. |

| Min Order Quantity | 1.00 Unit |

| Delivery Lead Time | As per order |

| Place of Origin | Turkey |

| Supply Ability | Customization as required |

| Packaging Details | Standard export packing |

| Transportation Details | Road / Ship |

Description

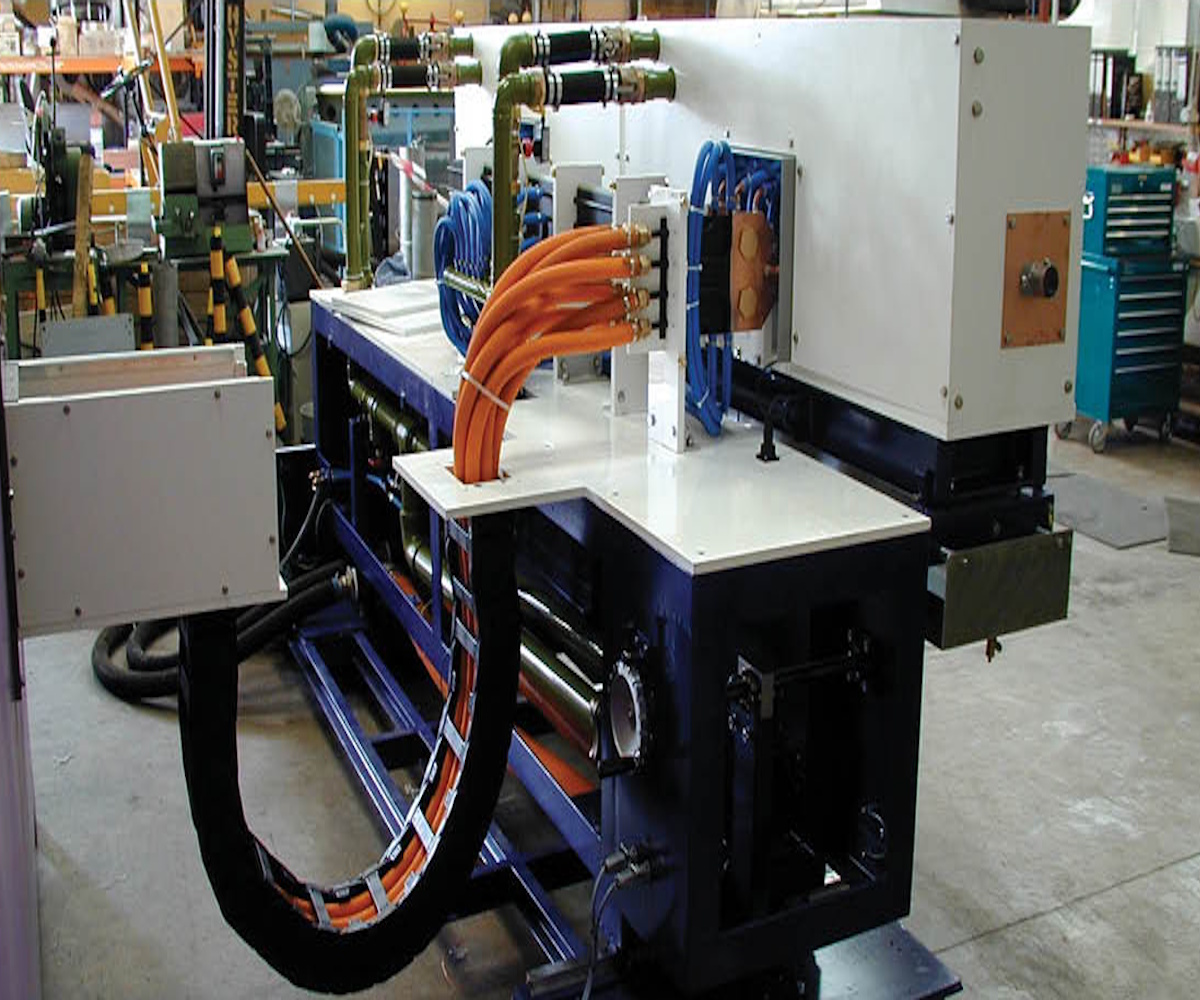

Aluminium Vacuum Brazing (VAB) systems are used to perform fluxless brazing of aluminum parts under high vacuum. Strict temperature uniformity, combined with low vacuum leakage and high repeatability, are essential for the process. VAB produces very clean, high-quality, and durable brazed joints. Consarc offers a wide range of aluminium brazing furnace designs for various applications, and offers the flexibility to customize custom designs to meet individual customer requirements.

Features:

- The highest uniformity of heating is achieved with closely spaced strip heating elements with their edges facing the workpiece

- +/- 5 o F temperature uniformity

- Multiple “trimmable” heating panels that balance the heat input to match the workload and stabilize the thermal characteristics

- The heat input is regulated by trimming the trimmable heating panels that cover the hot zone along its height to suit parts/charges of different heights

- The possibility of burns is reduced to a minimum by passing the aluminum deposits from the edge facing the bottom heating panels

- Hot zone panel modules can be easily removed to clean the hob, and individual panels can be removed without removing all the panels in the hot zone

- Panels are easy to repair; removed elements can be repaired in small areas without complete replacement

- The hot zone shields are placed both on top of each other and spaced apart to allow easy outgassing of the workpiece to ensure optimum vacuum performance

- The furnace chamber walls are kept warm to prevent condensation of air humidity when the door is open

- Insulated power feeders without water cooling to prevent magnesium condensation to reduce the possibility of arcing

- Internal inert gas cooling system or external air blowing cooling station option

- Fully integrated and automatic loading system

- Integrated Vacuum Degreasing furnace to provide a high efficiency “in-line” process system requiring minimal product carryover

- Extensive process experience

- PLC and PC SCADA providing fully automatic control of the brazing furnace and data recording

- Compliance with NADCAP and AMS2750 requirements where necessary

- Complete furnace system including all connections such as water lines, air lines, gas lines and electrical cables

- Installation is done after the assembly and functional tests are completed

Other Products

Post requirements