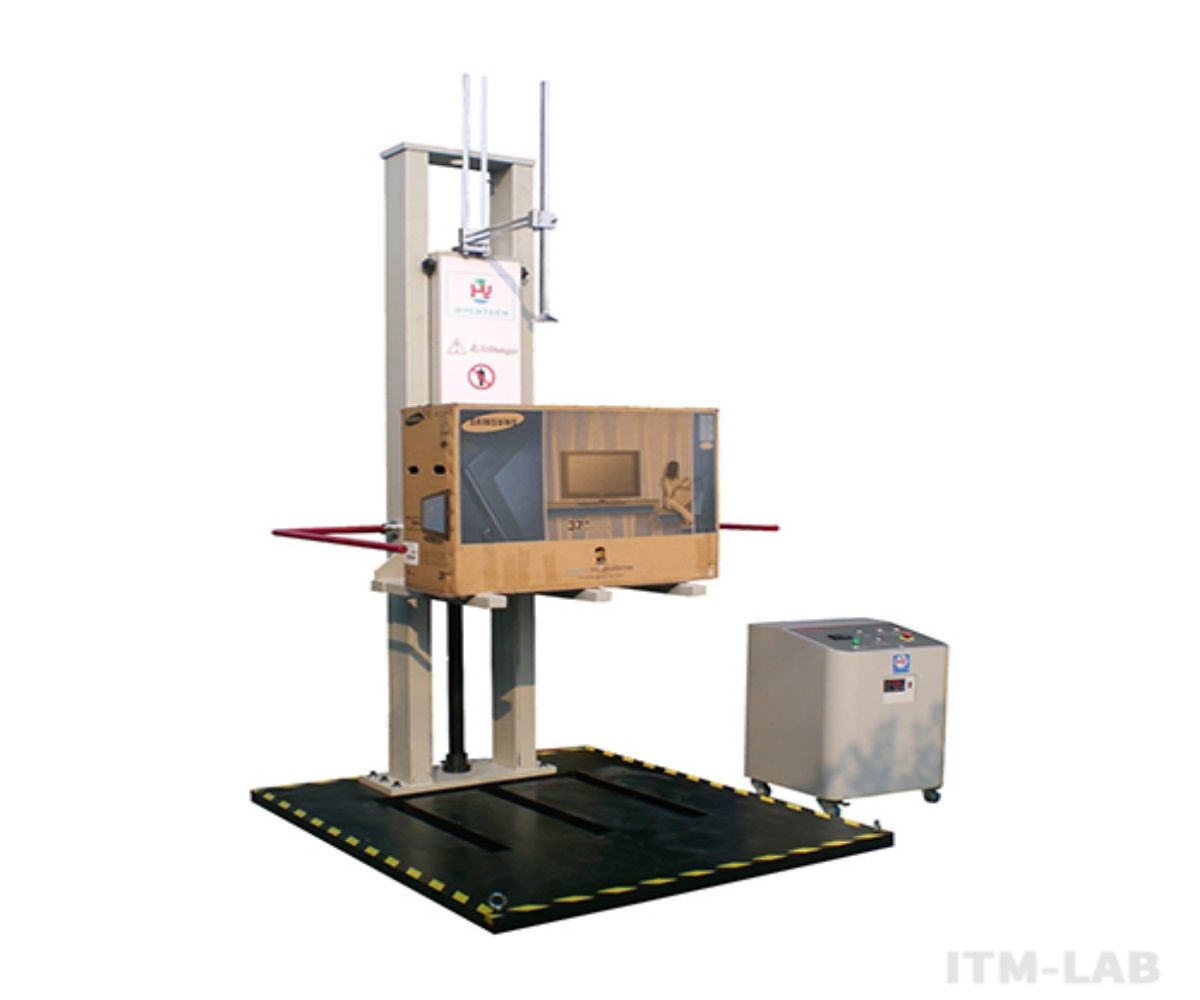

6axis Robot Auto Drop Tester

By: ITM-LAB Machine Inc| Price | Available on request |

| Category | Others |

| Manufacturer | ITM-LAB Machine Inc. |

| Min Order Quantity | 1.00 Unit |

| Delivery Lead Time | As per Order |

| Place of Origin | China |

| Supply Ability | Customization as required |

| Packaging Details | Standard export packing |

| Transportation Details | Road / Ship |

Description

All kinds of portable electronic products such as smartphones, tablet computers, e-books, electronic dictionaries, laptops, MP3 players, game consoles, VR, remote controls, etc, and peripheral products such as chargers, headphones, etc, as well as key parts such as touch module, glass cover, product shell, camera module, fingerprint module, antenna module, PCBA, soft pack battery, transmitter, receiver, etc due to accidental falling, damage, spontaneous combustion and explosion in the actual use process, the world's major brand manufacturers and parts manufacturers have increased product drop test, and the world has also formulated relevant test standards to standardize the test, such as IEC6006E-2-32, GB/T2423.8, JIS C 60068-2-32, YD/T1539 and other standards.

AS the product needs a drop verification test in the R&D stage, a verification drop test in the small-scale trial production stage and a spot check drop test after mass production, generally a mobile phone to do at least 500 drop tests from the R&D stage to mass production. In addition, each product test to be tested more than 20 times, so the demand for drop tests by major manufacturers is also increasing, However, the traditional drop testing machine must be clamped and placed by the operator, and the samples need to be picked up manually after the test. After the test, the operator can only visually detect whether the appearance is damaged, whether the TP module and CCD module are good, and whether the efficiency is low. And because the operator's operation can not be consistent, the test consistency is very poor, which misleads the R&D team's study.

Instead of manual work, the 6-axis robot is used to complete the loading and unloading of products, pick-up up falling behind, and automatically align the products with the falling sucker or fixture. It can automatically complete 24 kinds of falling ways of edges, comers and surfaces of 10 mobile phones or flat plates.

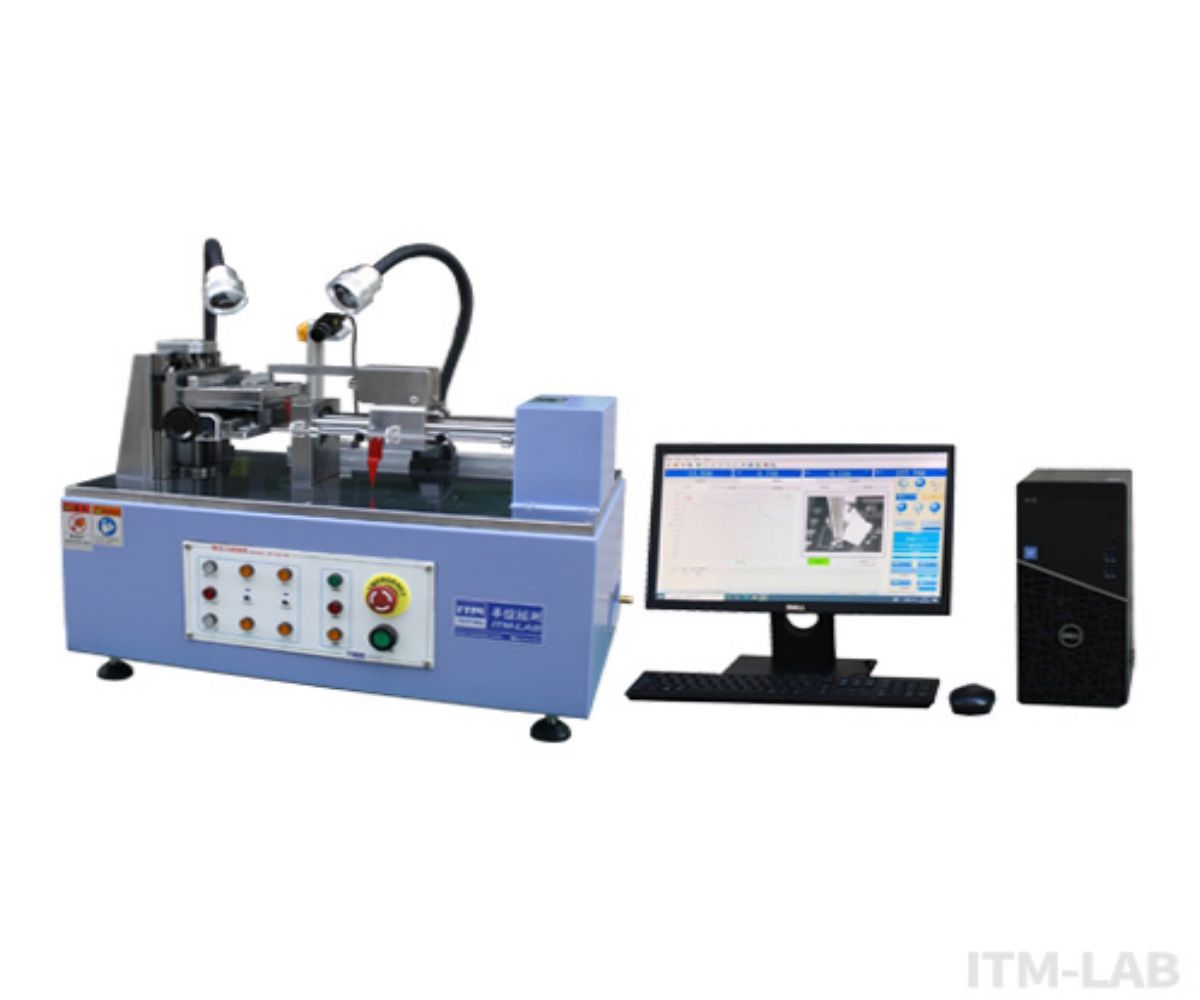

This machine is a high-tech product integrating artificial intelligence control, automatic test and visual recognition.

Other Products

Post requirements