Hot Chamber Die Castings

By: Kailas Toolings Pvt. Ltd.| Price | Available on request |

| Category | Industrial and Machinery Casting |

| Manufacturer | Kailas Toolings Pvt. Ltd. |

| Min Order Quantity | 10.00 Unit |

| Delivery Lead Time | 3-4 weeks |

| Place of Origin | Maharashtra, India |

| Supply Ability | Customization on Requirement |

| Packaging Details | Standard Export Packing |

| Transportation Details | Road/Ship |

Description

Die casting is the process of casting molten metal by forcing it into a pre-shaped mould. This process is commonly used in manufacturing industries for casting metals like zinc, aluminium, tin, copper and magnesium.

During die casting, newly molten metal is poured using pressure into a mould of the desired shape. The metal is then allowed to cool. Once it cools and hardens, it is taken out of the mould. Die casting process is of two types- hot chamber, and cold chamber die casting.

In hot chamber die casting, the metal is melted inside the casting machine, and not in a separate furnace. Hot chamber casting machines are also called ‘goose-neck machines'. They feature a built-in furnace to heat and melt the metal. Then, the molten metal is forced out of the furnace and into the die using a hydraulic-powered piston. This is a relatively quick process, taking about 15 to 20 minutes per standard cycle. It is not suitable for casting metals with high melting points, but is optimum for moulding zin, lead and tin alloys.

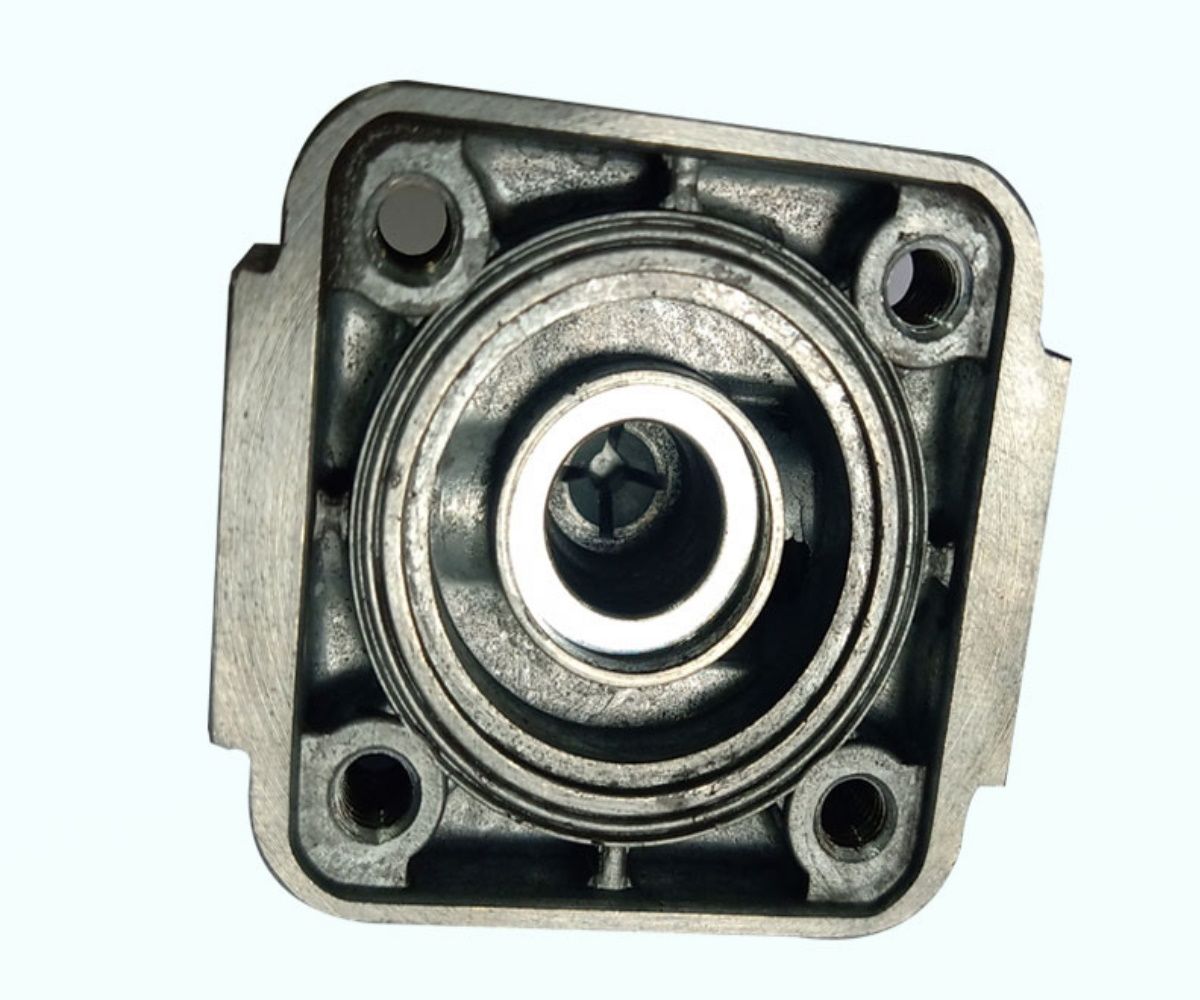

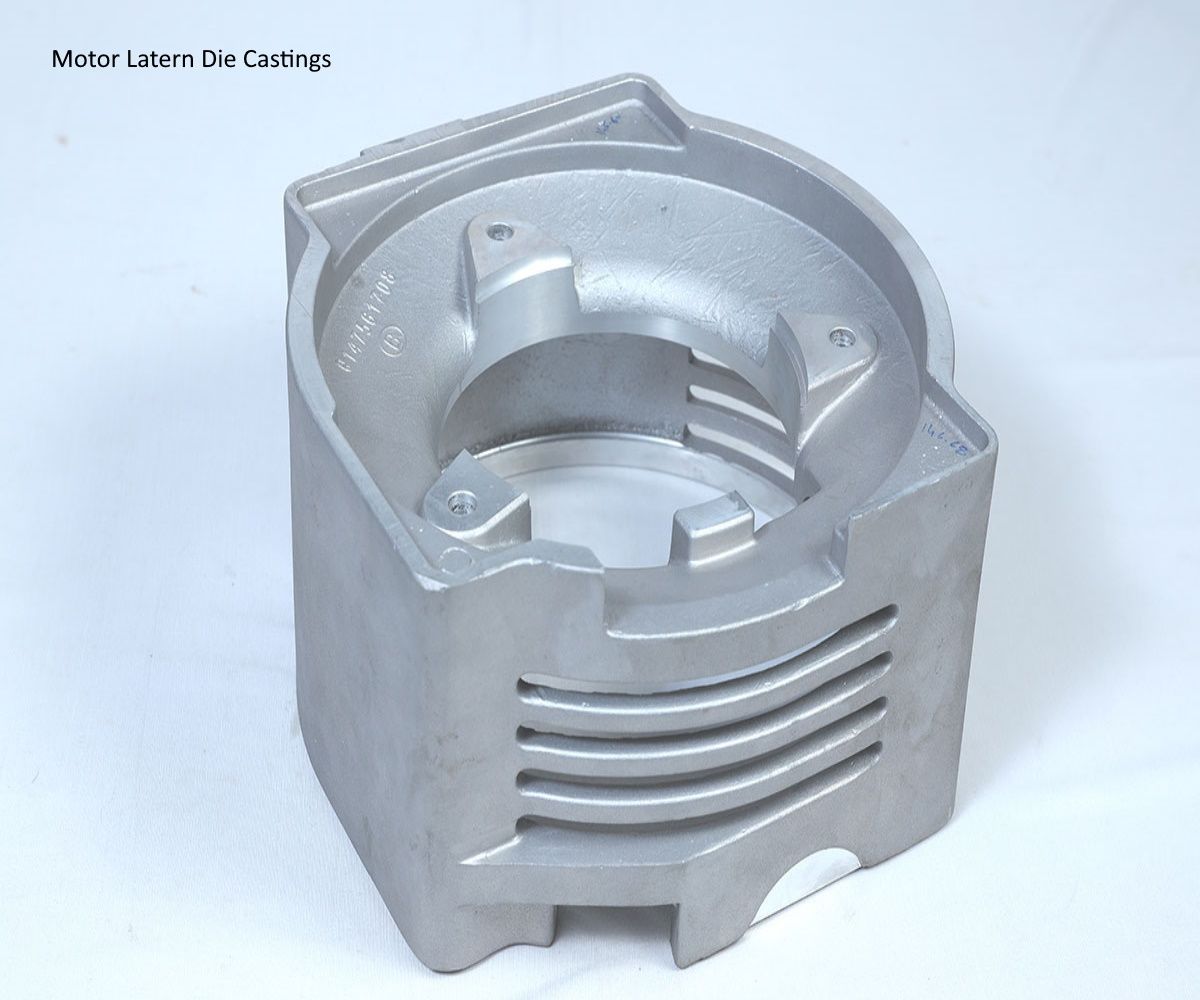

Apart from High Pressure Die Casting & Gravity Die Casting we also manufacture Hot Chamber Die Castings weight range from 10 grms. To 500 grms.

Refer attachment for product specification.

Other Products

Post requirements