Aluminium Billet

By: Mahed Aluminum Production Group| Price | Available on request |

| Types | 1- Import bill |

| 2- Standard billet | |

| 3- Billet DC | |

| 4- Remelting or conversion billet | |

| Category | Aluminium Billet |

| Manufacturer | Mahed Aluminum Production Group |

| Min Order Quantity | 25.00 MT |

| Delivery Lead Time | As per Order |

| Place of Origin | Iran |

| Supply Ability | Customization on Requirement |

| Packaging Details | Standard Export Packing |

| Transportation Details | Road/Ship |

Description

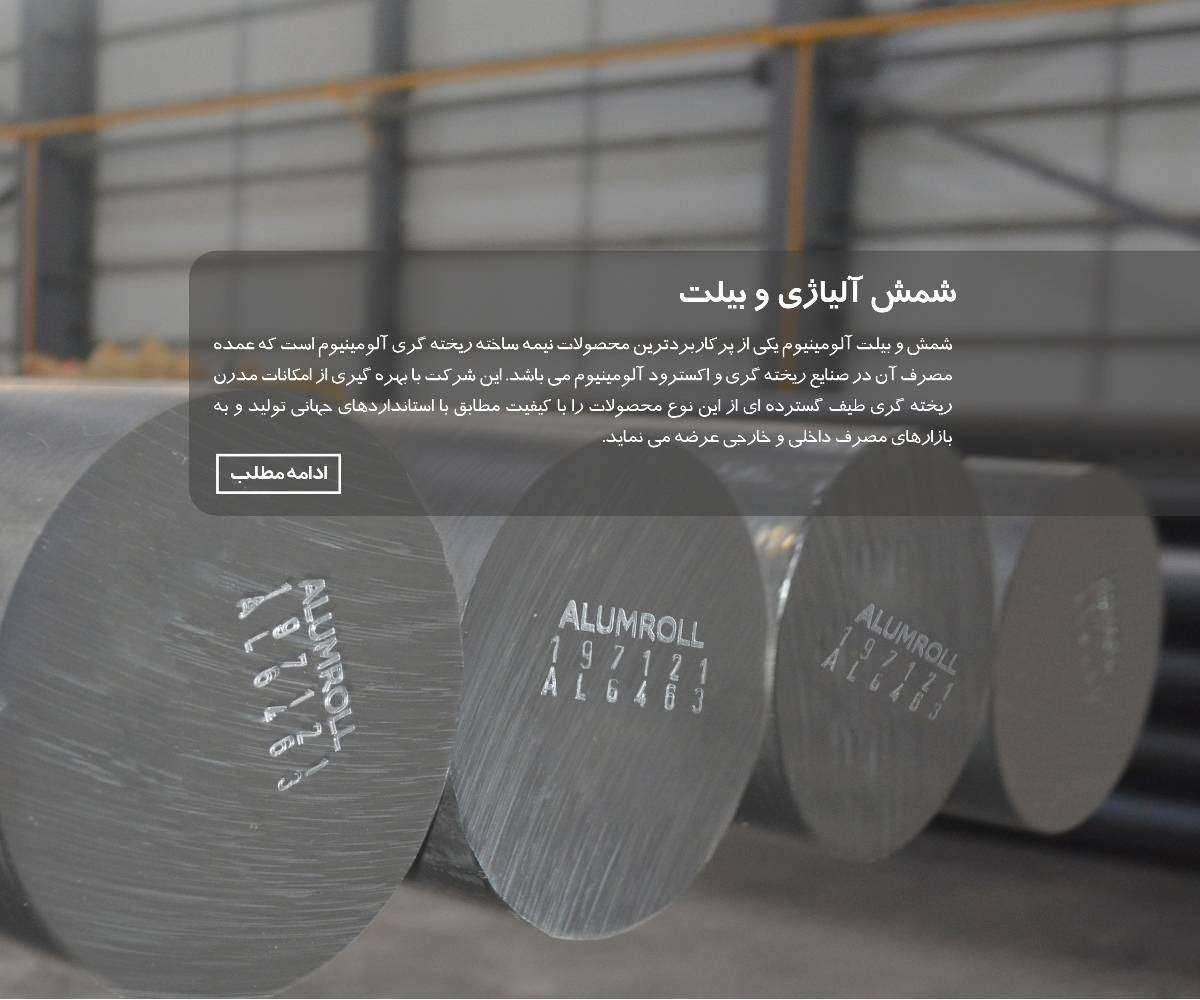

Aluminum billet is one of the most widely used semi-finished products of aluminum casting, which is mainly used in aluminum extrusion industries and is produced by continuous casting or DC method.The continuous casting process (DC casting) developed in 1933 is the method used today to produce aluminum extrusion billets. In this method, molten aluminum is poured into a round water mold with a shallow depth. This mold usually has a round cross-section, which starts to go down at a controlled speed when the melt starts to freeze in the mold, and water is sprinkled on the freshly frozen surface of the billet leaving the mold.

Recently, the use of larger DC casting machines with programmable control systems has increased. The use of sensors and computer software of automatic systems can control many casting parameters.

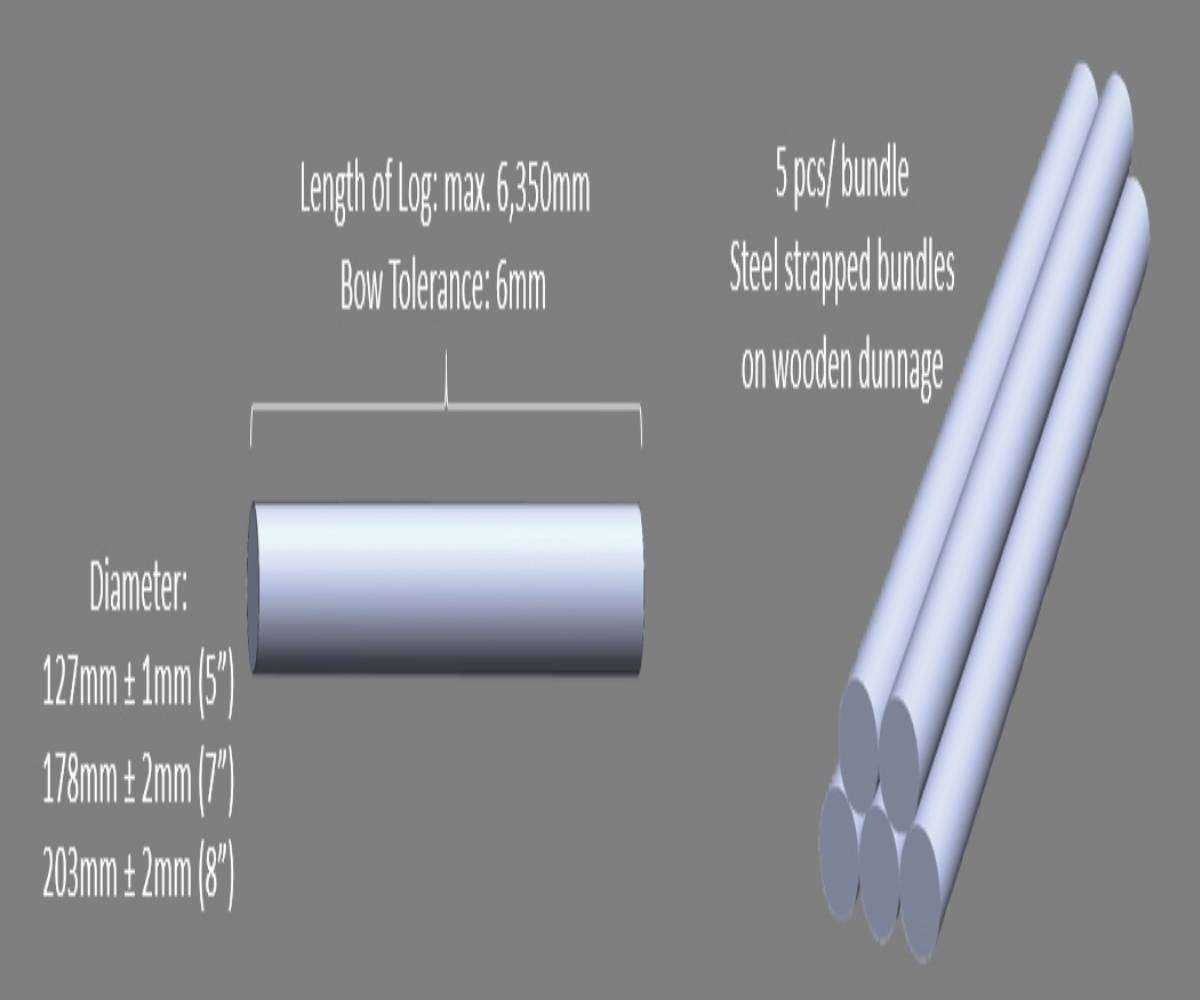

Different alloys and sizes of billets require different molds.

In aluminum billet casting, the molten metal in the furnace is sent to the degassing unit and then to the filtration unit and finally to the freezing unit using Direct vertical (DC) refrigerants are transferred. The DC casting method has advantages compared to other methods such as casting with a single die, especially for the production of high-strength alloys such as the 2000 and 7000 series:

1- minimal phase separation

2- the ability to produce large billets

3- the least number of cracks in high-strength alloys

4- slow and uniform transfer of the melt at a relatively low temperature to prevent many problems

In general, the quality of aluminum billet has a direct and indirect effect on the productivity and quality of the extrusion product.

Other Products

You may be interested in

Post requirements