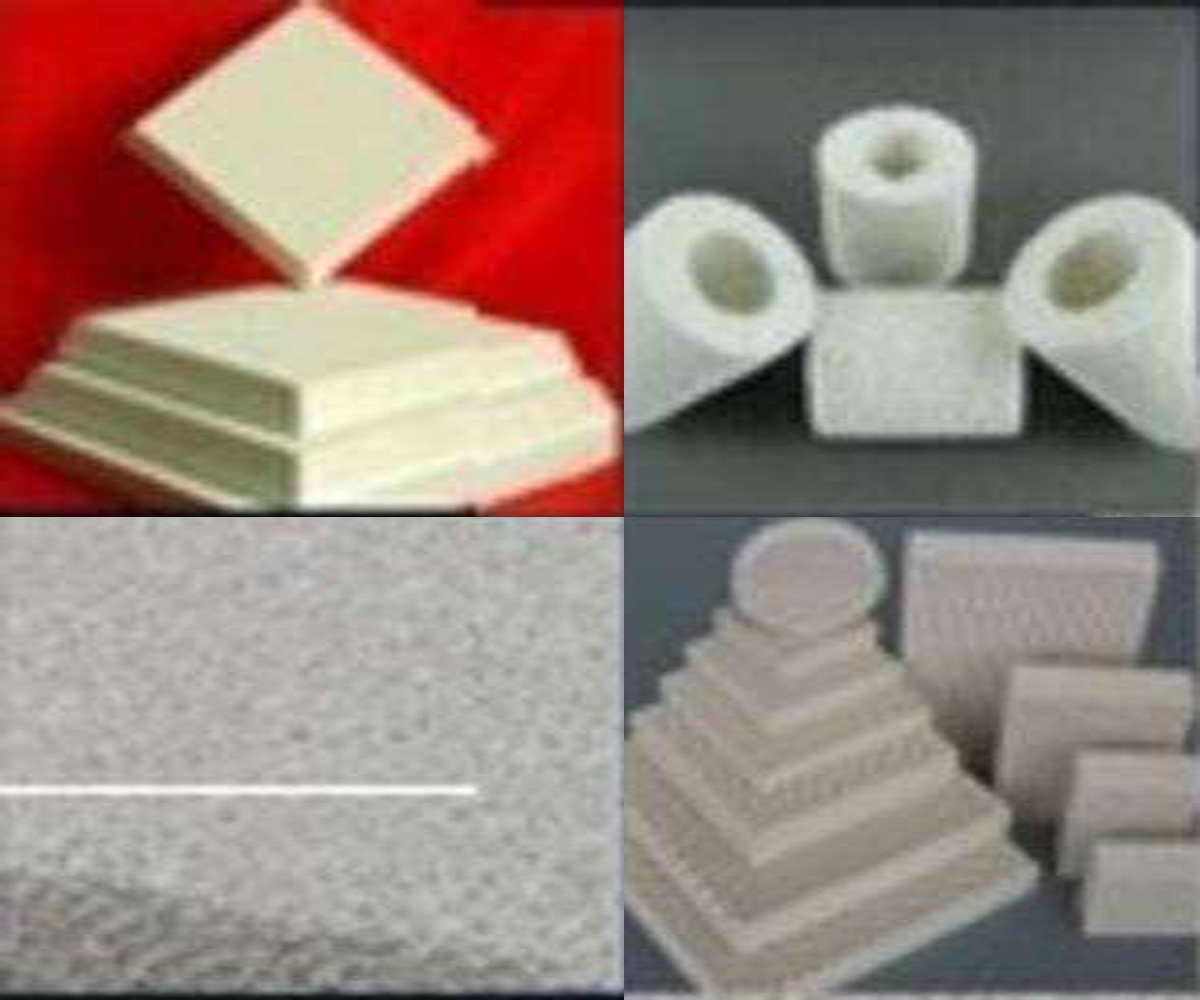

Ceramic Foam Filter

By: Prism Industrial Corporation| Price | Available on request |

| Category | Ceramic Consumables |

| Manufacturer | Prism Industrial Corporation |

| Min Order Quantity | 10.00 MT |

| Delivery Lead Time | As per order |

| Place of Origin | India |

| Supply Ability | Customization as required |

| Packaging Details | Standard export packing |

| Transportation Details | Road / Ship |

Description

USAGE:

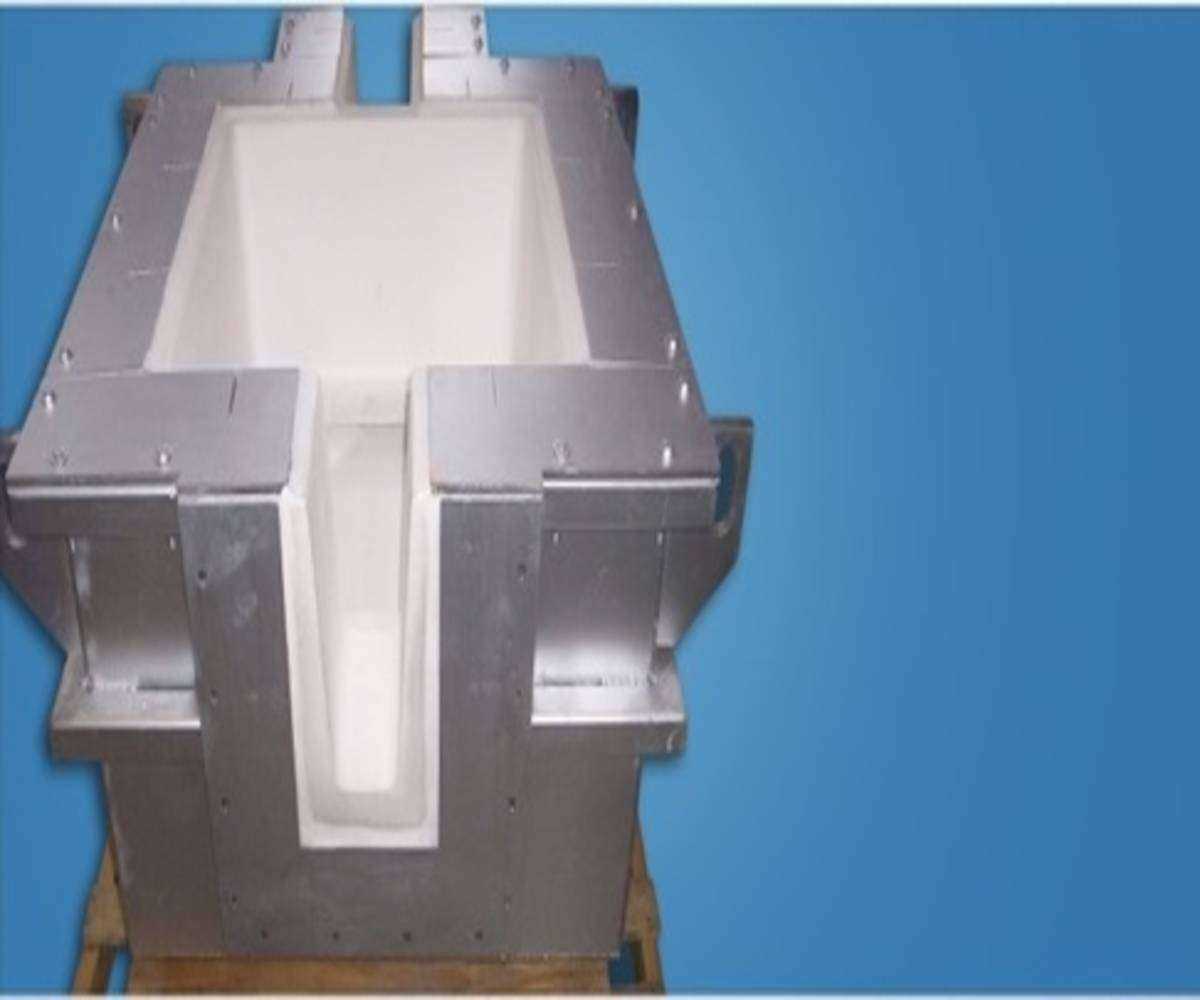

1. Clean the aluminium filter box; keep it clean and intact.

2. Put the ceramic foam filter into the filter box carefully, press the sealing gasket around and avoid molten aluminium dispersing or floating away.

3. Use electric or gas to preheat the filter box and ceramic foam filter evenly for 15-30 mins. Make the temperature next to the molten aluminium, the ceramic foam filter preheating temperature should surpass 460°C. Expansion cotton will seal after heating; it makes the ceramic foam filter steady in molten aluminium. Preheating ceramic foam filter pores open and avoiding occlusion expansion and contraction.

4. Observe the change of molten aluminium pressure, control the flowing molten aluminium needed and note the normal start pressure: 100-150 mm. The pressure falls down below 75-100 mm when molten aluminium is flowing; it will grow later.

5. Do not shock and beat the ceramic foam filter in filtration. Control molten aluminium flow rate in launder.

6. Take out the ceramic foam filter and clean the filter box after filtration.

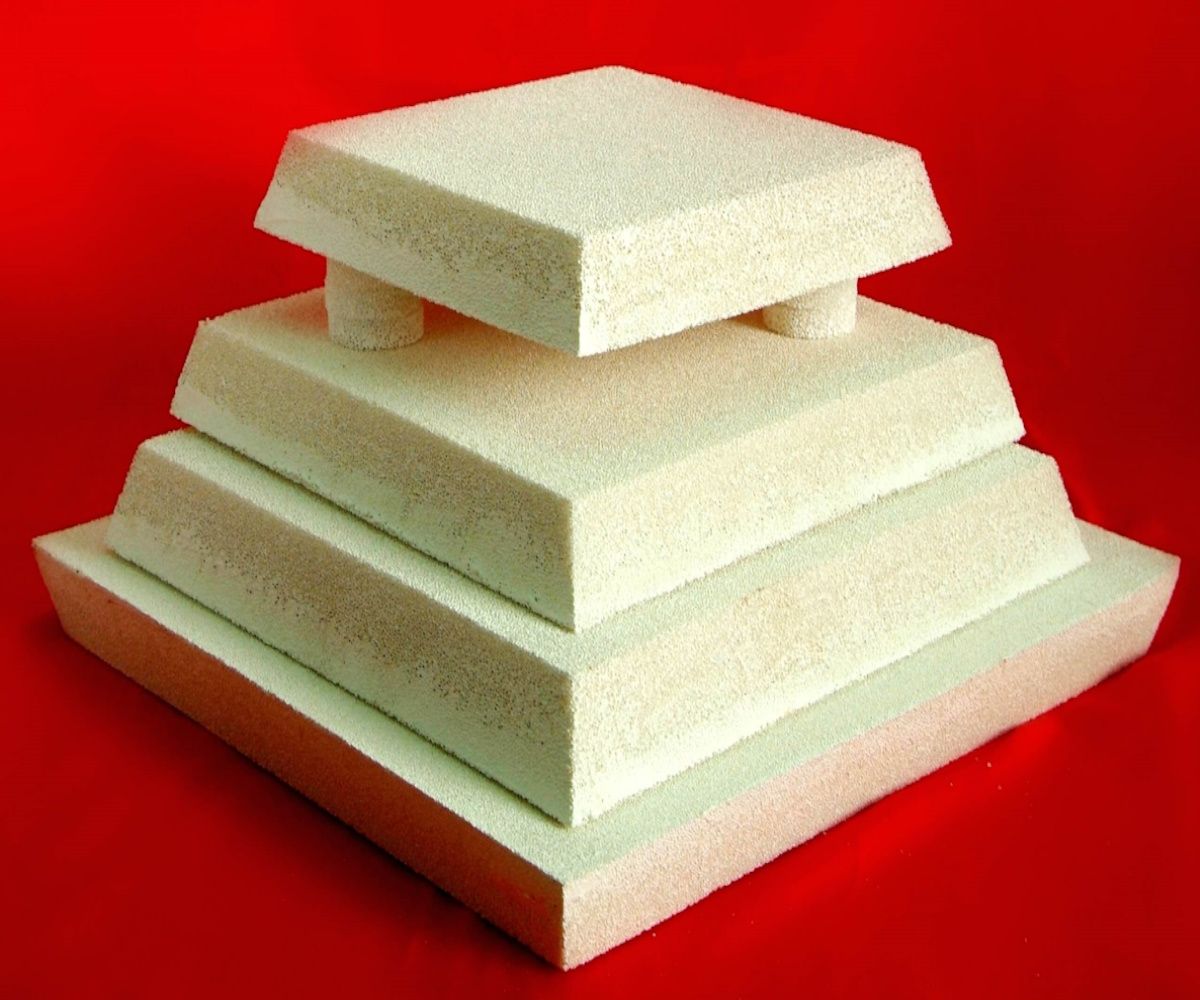

DATA OF APPLICATION:

|

Product Specifications (mm) |

Effective Filtration Area (%) |

Filtration Flow Range (kg/min) |

|

7in (178*178*50) |

68 |

22-42 |

|

9in (229*229*50) |

70 |

42-68 |

|

12in (305*305*50) |

73 |

60-135 |

|

15in (381*381*50) |

79 |

90-240 |

|

17in (432*432*50) |

80 |

125-310 |

|

20in (508*508*50) |

82 |

170-420 |

|

23in (584*584*50) |

84 |

230-580 |

Other Products

You may be interested in

Post requirements