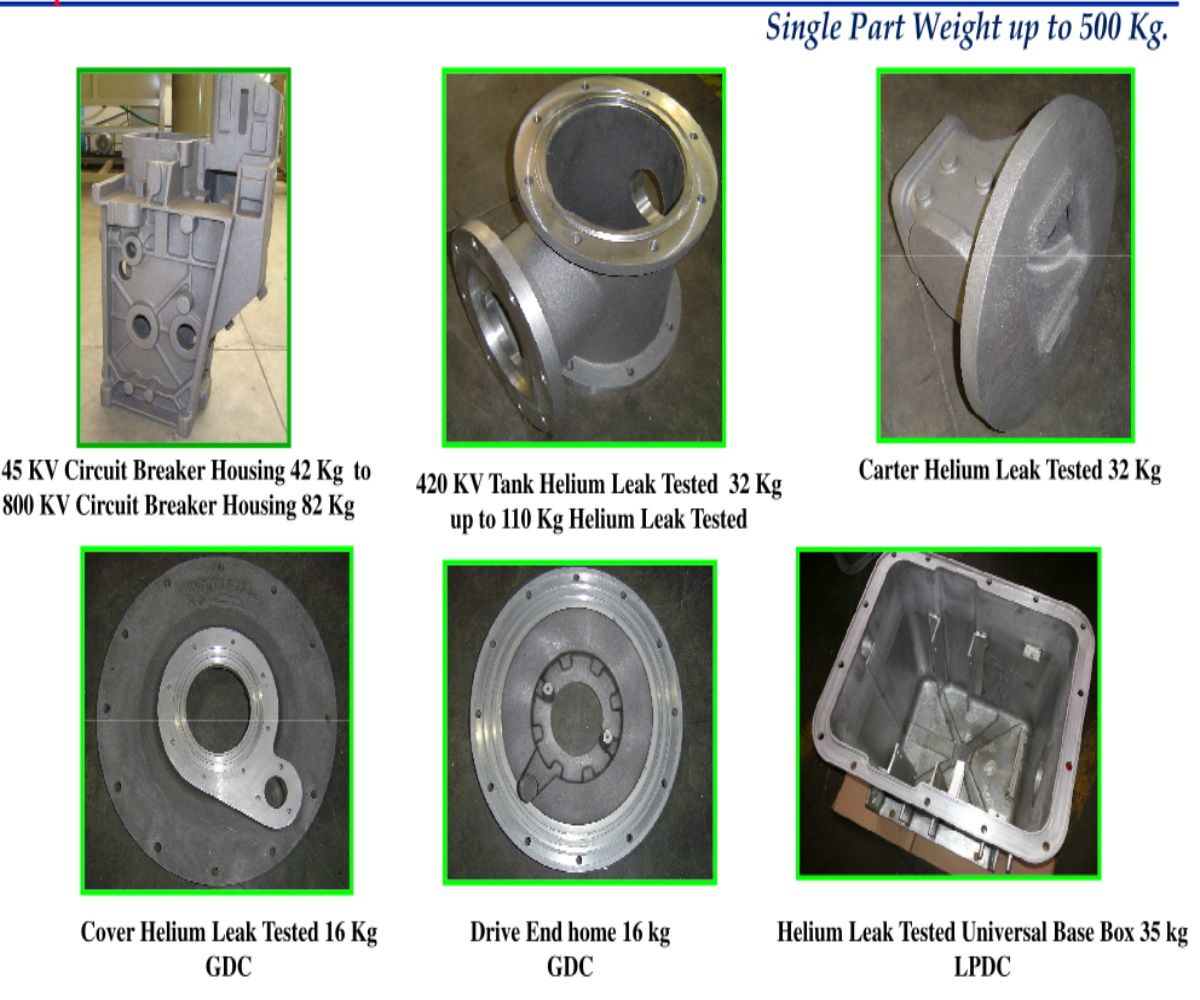

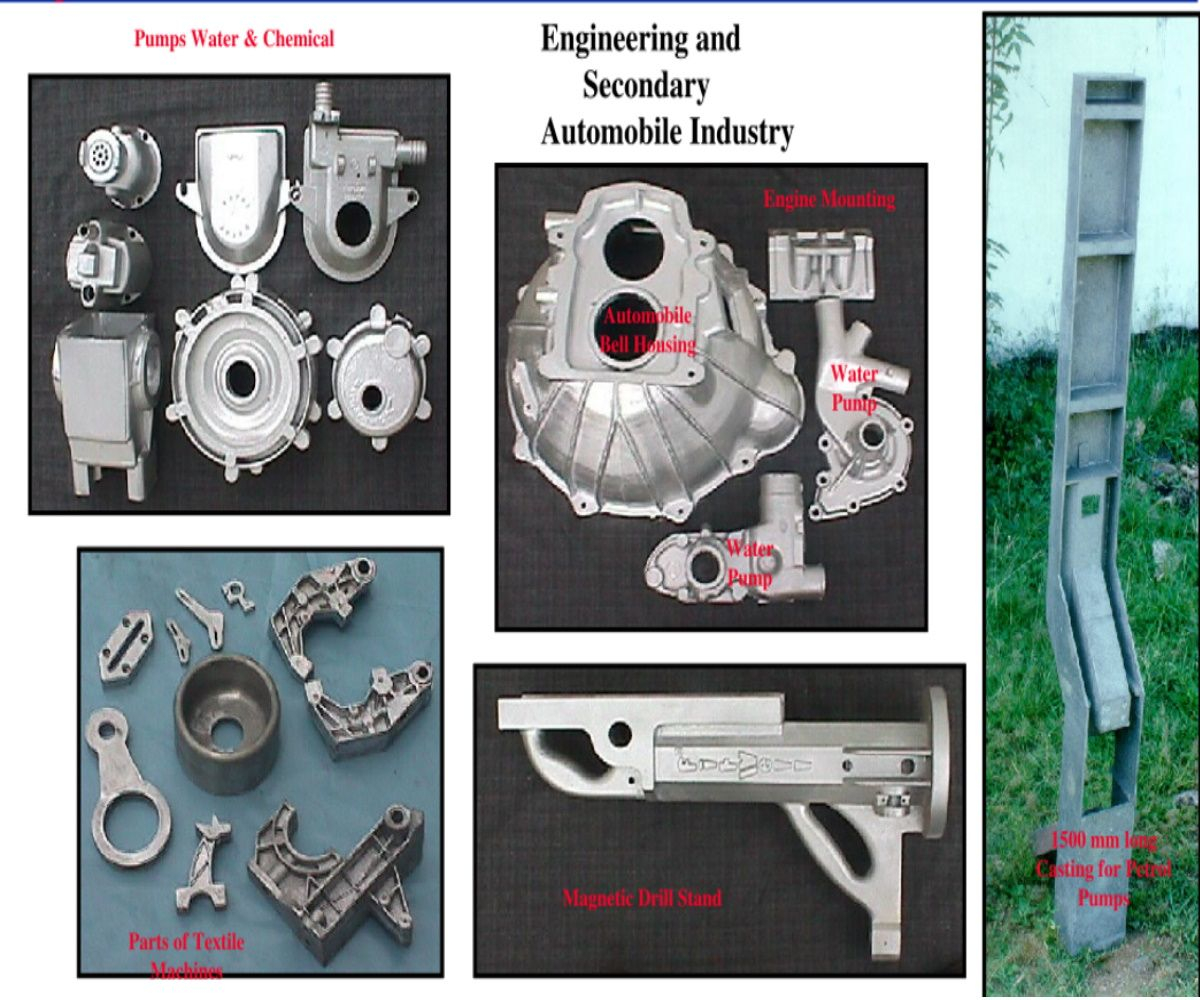

SUPER KINO EQUIPMENTS PVT LTD - Manufacturer of Casting Products for Engineering & Automobile Industry, Casting Products for Textile Industry, Castings for General Engineering Industries, Castings for Power Sector Industries, Castings for Flame Proof Explosion Proof Enclosures

Top Products

Late Mr. Sitaram Shah, chairman of the company launched a non-ferrous foundry in early sixties, specifically to cater an engineering units in and around Bombay. To build on this foundation, a full fledged machine shop facility was set up where most of the castings were machined before being shipped to the customers in late sixties.As a mode of forward integration and to keep pace with the rapidly changing business and economic scenario of the country, one more unit was added in mid seventies, to cater to specific demands of the customers like Painting and Electromechanical Assembly. This unit was initially catering to specific demands of cinematographic equipments but subsequently diversified and entered in the field of industrial and flameproof audio, lighting fixtures and other engineering products.

New foundry unit was set up in the year 1990 in 1000 Sq.meter of Industrial shed on 3000 meter plot at Umbergaon in the state of Gujarat, 140 Km north of Mumbai. Painted or Assembled.

Subsequently in the year 2009 another facility was build of 1200 Sq meter RCC structure where entire manufacturing facility like machining, Testing, Finishing & Product building was shifted from Mumbai next to Existing Foundry unit.Today, Superkino is in a position to produce Aluminum castings ranging from a few grams in GDC upto 170 kg Single piece in Sand Casting with quantity ranging from few pieces to a few thousand pieces in Raw Cast form, Duly Heat Treated , Machined , Painted or Assembled. Super Kino is also fully equipped to manufacture any kind of electromechanical assembly based on castings. Superkino has now fully developed and independent business divisions viz. Underwater Lights & LOCA condition lighting for Nuclear Power stations & Transformer Accessories which deliver seamless products to customers both in India as well as outside India.