Victory Precisions Pvt. Ltd. - Aluminum Die Casting foundry and Precision Machining Facility

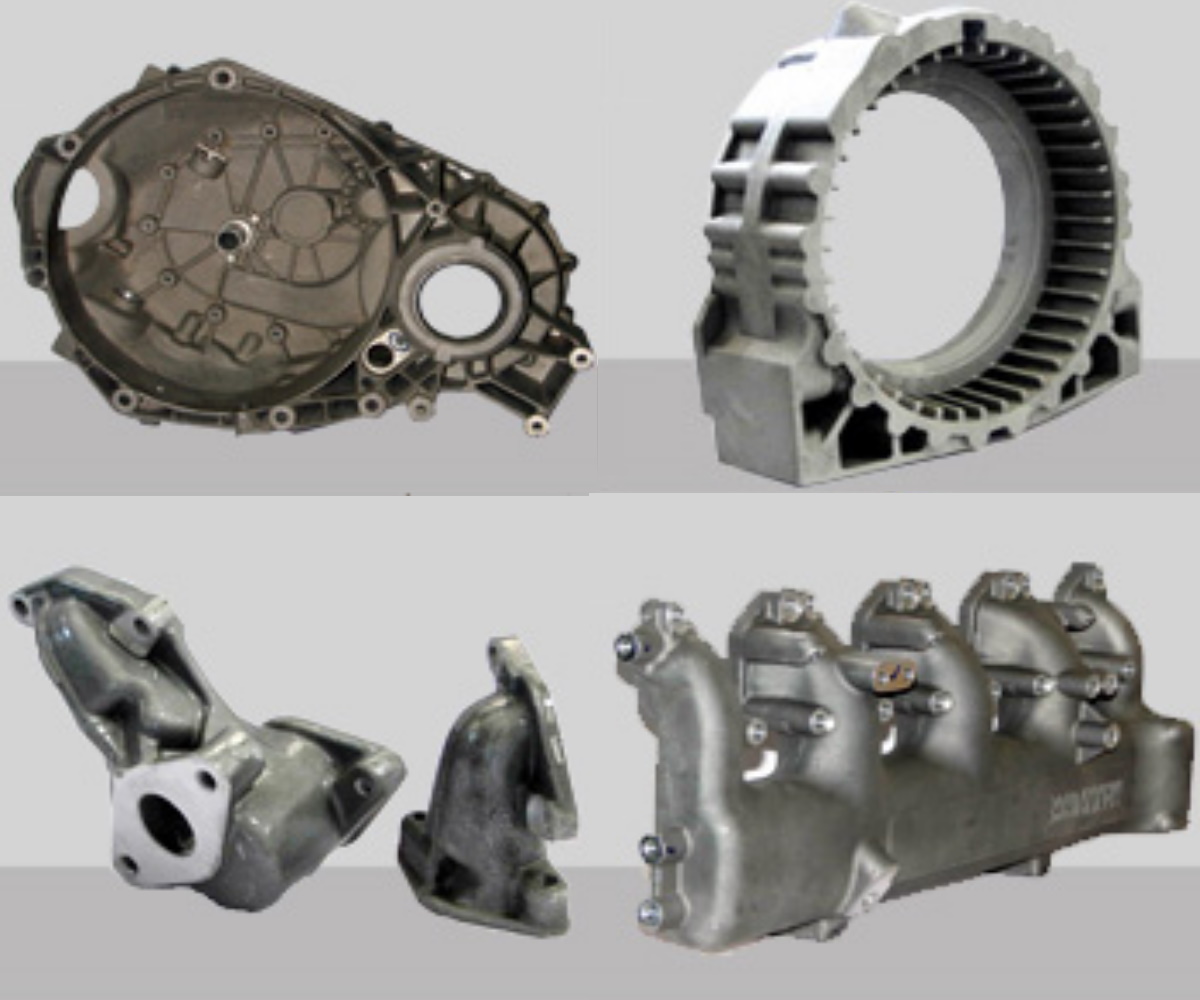

Top Products

Victory Precisions Pvt.Ltd. is an aluminum die casting foundry and precision machining facility located in Chakan which today is the top notch industrial area of Pune. We at Victory Precisions produce high quality aluminum die casting components for automotive as well as non automotive applications. We cater to a broad spectrum of aluminum casting requirements for National/International specification based on customer requirement.

Since 1999 our group company Alpha Dies & Pattern India Ltd has incorporated its own tool room facility with latest CAD & CAM software as well as a large number of vertical machining center. We are now able to manufacture in-house dies, moulds and patterns for our valuable customer.

We started our CNC machining division in year 2005 in response to customer request for finished machining parts. Since our inception we have been diligently performing high precision machining and assembly work for our reputed clientele. With support and technical proficiency from our sister concern company Alpha Dies & Patterns India Pvt. Ltd. Victory Precisions has started its own aluminum foundry operations in 2009. The facility is specially setup for gravity die casting parts.

Aluminium Foundry -

As a complex and critical casting manufacturer, Victory has been offering complete solutions from concept to production stage.

Our mission is to produce & provide the aluminium die casting parts with highest quality at a competitive price with value added services.

Currently the foundry occupies 20,000 sq ft covered area with 50 skilled people.

Foundry Set Up :

|

Facility |

Capacity / Size |

Nos |

|

Floor Space Area |

60 mtr X 12.5 mtr |

2 |

|

Floor Space Area |

60 mtr X 4 mtr |

1 |

|

Melting Furnace |

300 k.g - Diesel (120 ton P.M) |

1 |

|

Melting/Holding Furnace |

300 k.g - Electric (60 ton P.M) |

2 |

|

Holding Furnace |

150 k.g - Electircal |

1 |

|

GDC station tilting |

1200 mm X 1500 mm |

3 |

|

GDC station tilting |

600 mm X 700 mm |

3 |

|

GDC station stationary |

600 mm X 700 mm |

4 |

|

Decorring Furnace |

1000 k.g |

1 |

|

Riser Cutting Machine |

4.4 mtr X 4.5 mtr |

2 |

|

Core Shooter |

400 X 600 / 600 X 800 |

2 |

|

Short Blasting Machine |

48 inch - Double Door |

1 |

|

Vaccum Imprignation Plant |

Dia .1000mm X Ht 2500 mm |

1 |

|

Heat Treatment Plant |

(T6- 1000 k.g - Drop Quench Type |

1 |

|

Core Baking Oven |

|

1 |

|

Nitrogene Metal Degassing |

|

1 |

| Automatic Sand De-coring | 3 |

Powder Coating / Anodizing / Surface treatment facilities provided to our customer by trusted outsourcing agency.