Aluminium Titanium Boron

By: Qinhuangdao Fengyue Science & Technology Co., Ltd.| Price | Available on request |

| Application | DC, CC and Die Casting |

| Material | Aluminium, TiB2, TiAl3 |

| Category | Other Casthouse Consumables |

| Manufacturer | Qinhuangdao Fengyue Science & Technology Co., Ltd. |

| Min Order Quantity | 10.00 MT |

| Delivery Lead Time | As per order |

| Place of Origin | Qinhuangdao, China |

| Supply Ability | Customization as required |

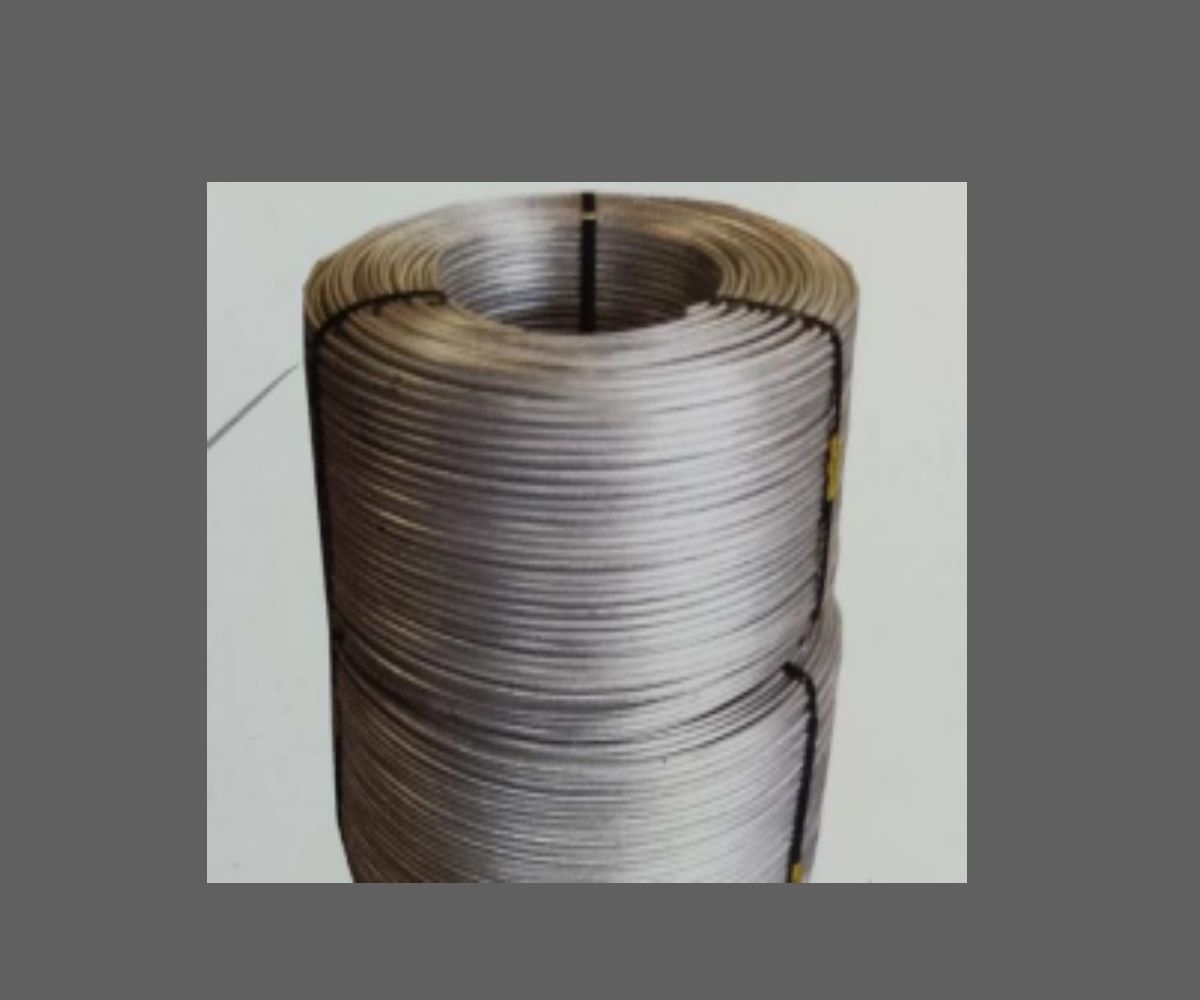

| Packaging Details | 1.Cut Rod: Diameter isΦ9.5±0.3mm, 500-1000mm, 1 ton/pallet or wooden case. 2.Coil Rod: Diameter is Φ9.5±0.3mm, 185-210kg/coil, 3coils/pallet |

| Transportation Details | Road / Ship |

Description

The addition of titanium boron aluminium grain refiner improves homogeneity and allows for a uniform distribution of alloying elements, reduces porosity, eliminates hot tearing in cast structures, improves responsiveness to subsequent heat treatment and enhances mechanical properties and machinability in the fabrication process. Continuous injection of a titanium boron aluminium rod is a highly effective treatment for all aluminium alloys. High fluidity, allowing faster casting speeds, ensures a good refining effect. Better homogeneity of the alloy and uniformity of the structure eliminate columnar crystal and feather-like crystal structure. Reduce the internal shrinkage, hydrogen porosity, hot cracking and segregation tendency and improve the intrinsic quality of aluminum products. Improvement of the surface quality, improvement of the response to finishing treatment.

Technology Advantages:

1. High fluidity allowing faster casting speeds, ensure good refining effect

2. Better Homogeneity of the alloy and uniformity of the structure; Eliminate columnar crystal and feather like crystal structure

3. Reduce the internal shrinkage, hydrogen porosity, hot cracking and segregation tendency, improve the intrinsic quality of aluminum products

4. Improvement of the surface quality, improvement of the response to finishing treatment

5. Enhancement of mechanical properties and increase of the strength and toughness of aluminum alloy

6. Improve the ductility of aluminium products, for the subsequent processing of the plastic deformation of the process to bring greater flexibility and reduce the process of surface defects

7. In the rolling process of aluminium profile, the product calendering quality and the productivity rate of rolling can be improved and the life of lengthen rolling dies and auxiliary equipment life

Other Products

You may be interested in

Post requirements