Aluminium Alloy

By: RAJ METALS & ALLOYS| Price | Available on request |

| Category | Master Alloy Shapes |

| Manufacturer | RAJ METALS & ALLOYS |

| Min Order Quantity | 10.00 MT |

| Delivery Lead Time | As per order |

| Place of Origin | India |

| Supply Ability | As per requirement |

| Packaging Details | Standard Export Packing |

| Transportation Details | Road/Ship |

Description

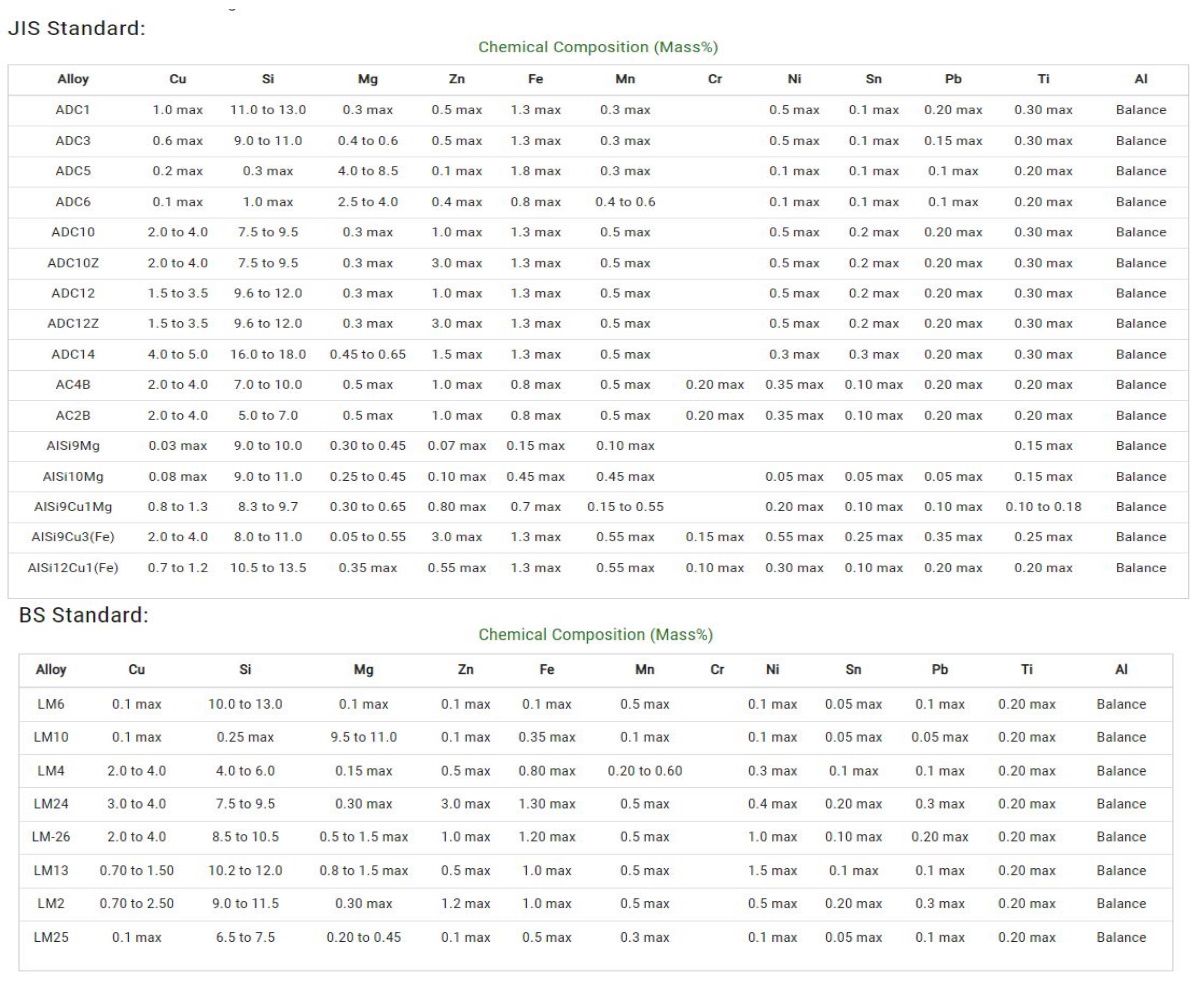

Aluminum alloy (or aluminum compounds; see spelling contrasts) are composites in which aluminum (Al) is the overwhelming metal. The typical alloying components are copper, magnesium, manganese, silicon, tin and zinc.. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories heat-treatable and non-heat-treatable. About 85% of aluminium is used for wrought products, for example rolled plate, foils and extrusions. Cast aluminium alloys yield cost-effective products due to the low melting point, although they generally have lower tensile strengths than wrought alloys . The most significant cast aluminum composite framework is Al–Si, where the abnormal amounts of silicon (4.0–13%) add to give great throwing qualities. Aluminum compounds are broadly utilized in designing structures and segments where light weight or consumption obstruction is required.

Wrought Alloys : Any Alloys that are turned into consumer products by solid state process – extrusion , forging and rolling.

You may be interested in

Post requirements