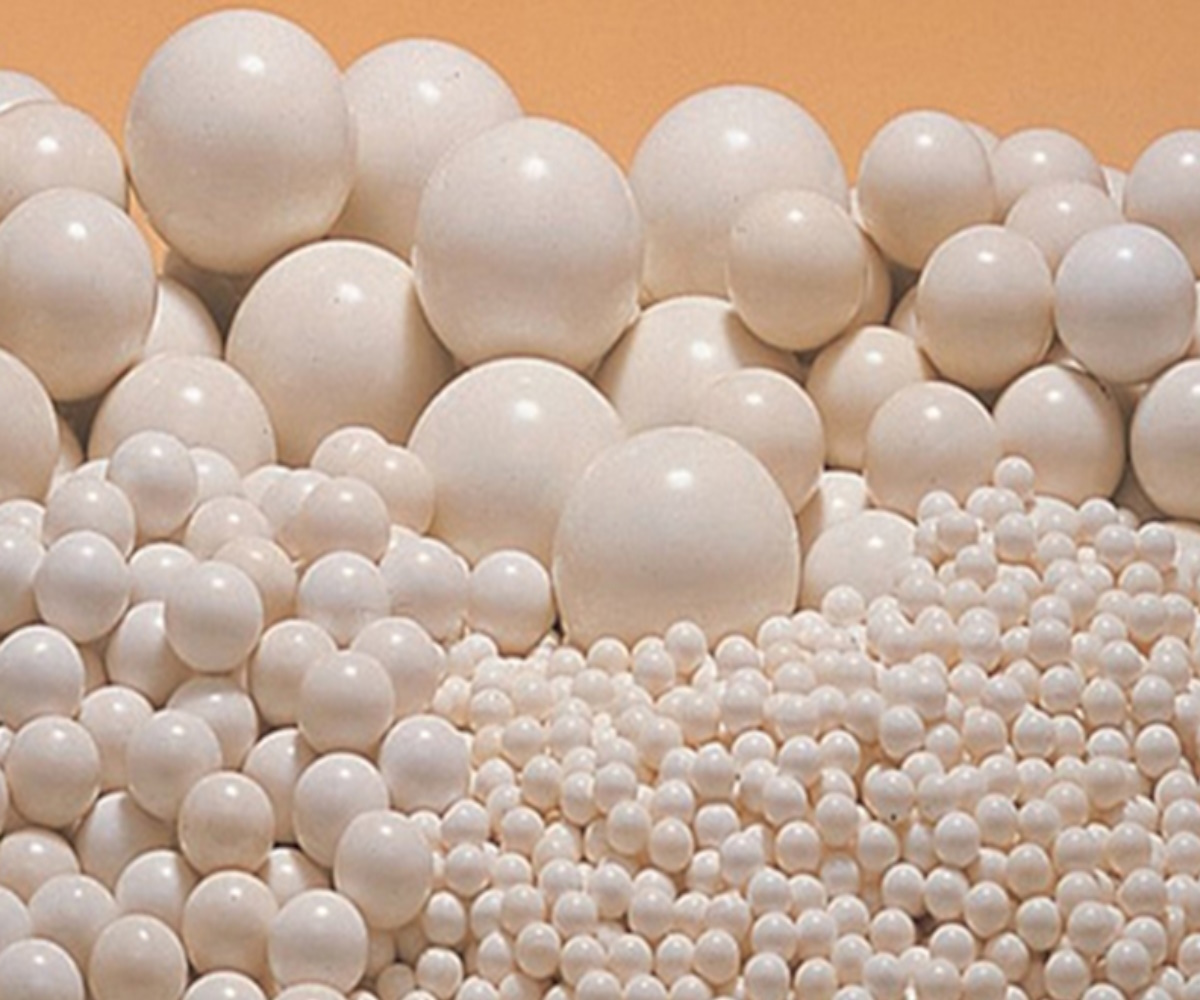

High Purity Alumina Beads

By: Sanxin New Materials Co., Ltd.| Price | Available on request |

| Category | Alumina Products |

| Manufacturer | Sanxin New Materials Co., Ltd. |

| Min Order Quantity | 10.00 MT |

| Delivery Lead Time | As per order |

| Place of Origin | China |

| Supply Ability | Customization as required |

| Packaging Details | Standard export packing |

| Transportation Details | Road / Ship |

Description

High purity alumina beads (SXHAB) are ceramic grinding media renowned for their exceptional hardness, wear resistance, and chemical stability. Composed predominantly of 99.9% aluminum oxide, they are produced using advanced ceramic manufacturing techniques. These beads find extensive application in high-tech industries like electronics, aerospace, and biotechnology, where the purity and performance of materials are of paramount importance. Moreover, they are widely employed in the production of advanced ceramics, either as raw materials or as grinding media, to achieve precise and consistent particle size distributions.

The exceptional hardness of high purity alumina beads enables them to withstand rigorous grinding processes without undergoing deformation or breakage. This characteristic ensures extended service life and consistent performance during grinding operations. The beads' outstanding wear resistance further contributes to their longevity, reducing the need for frequent replacements and maintaining their shape and size throughout the grinding process.

Chemical stability is another key attribute of high purity alumina beads. They exhibit excellent resistance to chemical corrosion, making them compatible with a broad range of substances and minimizing the risk of contamination during grinding. This chemical stability is particularly critical in industries where material purity and integrity are essential, such as electronics and biotechnology.

High purity alumina beads play a vital role in the production of advanced ceramics. They can be used as raw materials, contributing to the formulation of precisely engineered ceramic compositions. Additionally, as grinding media, they facilitate the achievement of consistent and controlled particle size distributions in ceramic manufacturing processes. This ensures the production of high-quality ceramics with desired physical and mechanical properties.

Feature:

- High hardness

- Chemical stability

- Consistent particle size distribution

- Low contamination

Application:

- Dielectric, piezoelectric, magnetic substance materials

- Rare earth phosphor material

- Lithium battery electrode material

- CMP Polishing powder

- High grade pigment and ink

- Medicine, pesticide, antibiotic material and food

- High performance ceramic materials

Other Products

Post requirements