Flux 475 (Rotary Furnace Flux)

By: Scottish Chemical Industries| Price | Available on request |

| Specification: | |

| KCL | 47.5% |

| NaCl | 47.5% |

| Cryolite | 5% |

| Category | Degasser and Fluxes |

| Manufacturer | Scottish Chemical Industries |

| Min Order Quantity | 500.00 KG |

| Delivery Lead Time | 7-10 Days |

| Place of Origin | Maharashtra, India |

| Supply Ability | Customization on Requirement |

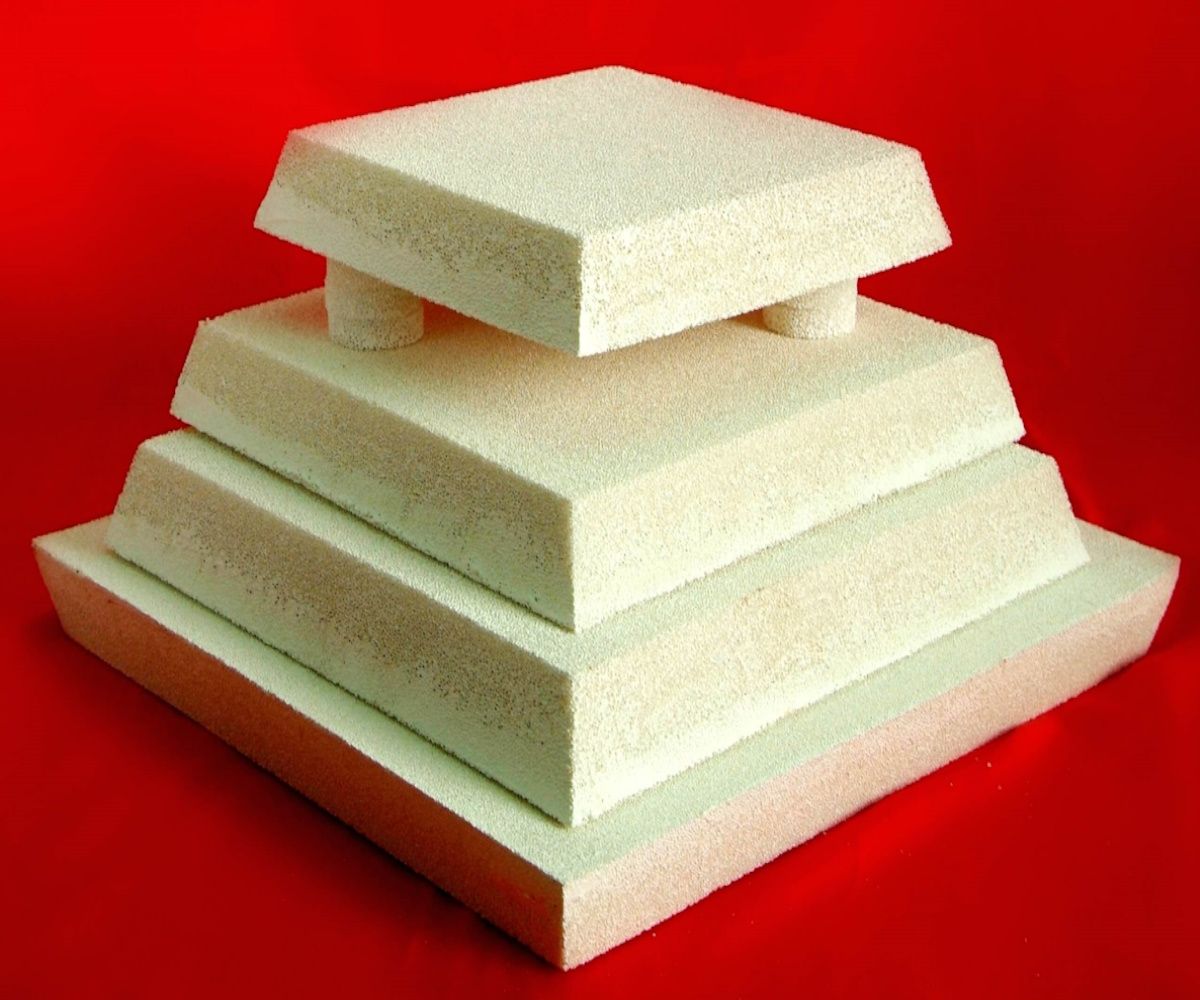

| Packaging Details | 25 Kg / HDPE lined bags 1 Ton / Jumbo Bag Note: 1. Flux must be stored in a cool and dry place to avoid moisture pickup |

| Transportation Details | Road / Ship Transport |

Description

The most commonly used furnace in the secondary aluminium industry is the rotary furnace where aluminium scrap is melted under a layer of salt which consists of a mixture of chlorides and cryolites. There are various possible combinations of this salt flux. However after several trials and customers feedbacks, Flux 475 has proved to be the best combination for Aluminium melting in rotary furnace.

Advantages:

- Flux 475 enhances the heat transfer to the metal

- It prevents the oxidation of the metal

- The salt takes up contaminants, such as oxides, carbides and others contained in the scrap or produced by reactions during the melting process

- Homogenous mixture for the alloy is achieved

- Helps in cleaning, covering as well as drossing of molten aluminium

Other Products

Post requirements