Aluminium Melting and Holding Furnace

By: SECO/WARWICK| Price | Available on request |

| Category | Holding Furnace |

| Manufacturer | SECO/WARWICK |

| Min Order Quantity | 1.00 Unit |

| Delivery Lead Time | As per order |

| Place of Origin | Poland |

| Supply Ability | Customization as required |

| Packaging Details | Standard export packing |

| Transportation Details | Road / Ship |

Description

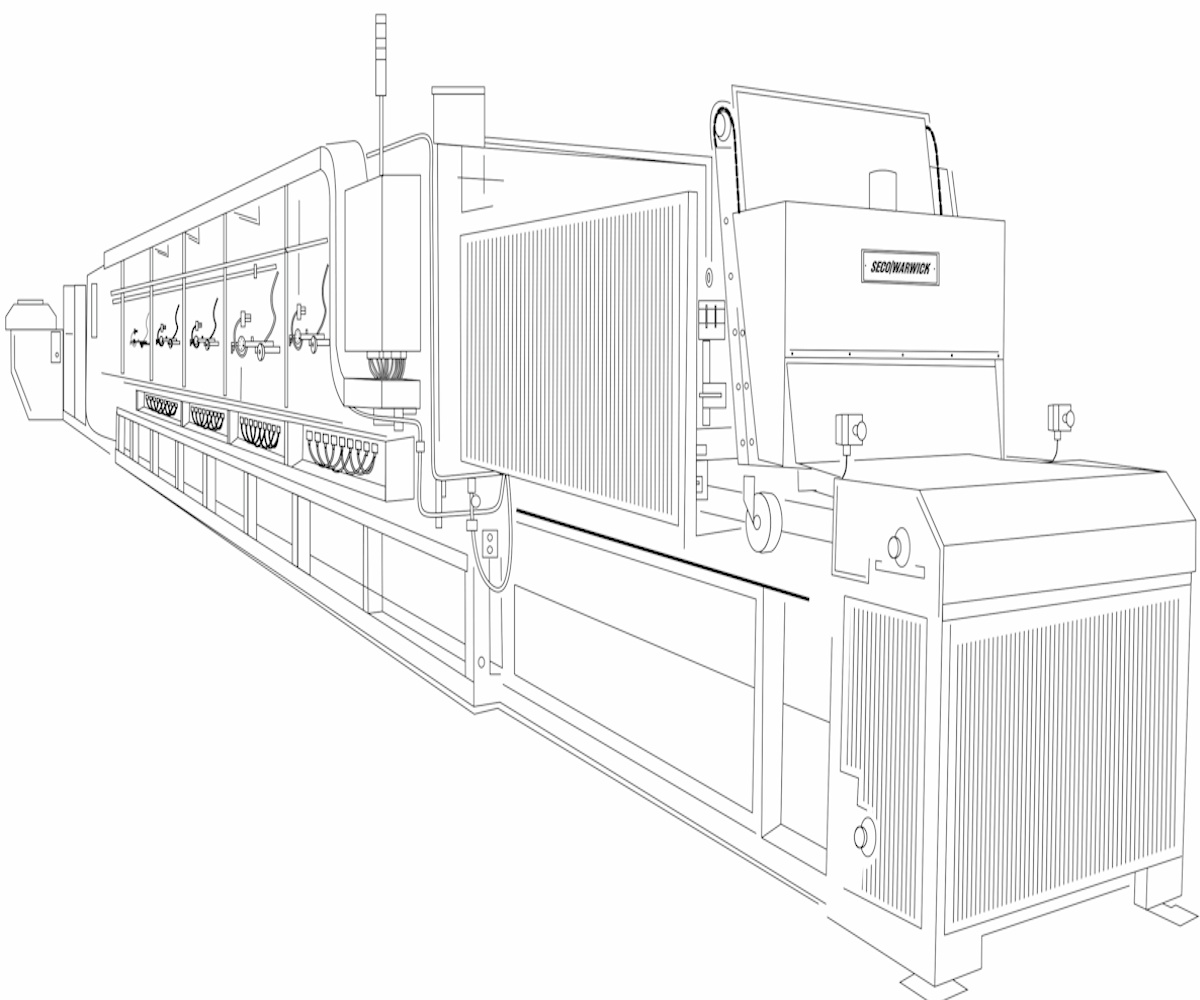

Melting and holding equipment available for their customers from North and South America. The design elements and unique features that go into the their line of aluminium melting and holding furnaces are tried and proven, as the roots of their history run deep. When you choose SECO/WARWICK as your aluminium furnace supplier, the furnace system is engineered to meet your specific needs and requirements.

SECO/WARWICK furnaces come in many types, shapes and sizes with melt rate and capacities to meet your specific requirement and provide many years of efficient and dependable service. Our engineering staff works closely with your plant engineering, production, and maintenance staff from start to finish to ensure optimum performance for the furnace system and integration with upstream and downstream plant operations.

Advantage:

Furnace Design

SECO/WARWICK delivers complete solutions. We offer superior construction, advanced control systems, combustion system options, hi-performance refractory linings, and turn-key installation service to help you obtain more from your casting process.

Control

SECO/WARWICK incorporates the latest PLC based control hardware and software providing optimal furnace system control. Combustion fuel to air ratios and combustion input are optimized to achieve targeted metal set points and provide highly efficient results. SCADA and Ethernet communication capabilities allow interface communication with casting stations and other up and downstream processes. Remote communication capabilities allow display of furnace system alarms, set points and fuel usage from your remote PC or smart phone. These remote capabilities afford you the knowledge required to keep your process on track.

Combustion Systems

SECO/WARWICK works with all burner manufacturers to determine and select the burners best suited for your specific application, balancing your need for performance vs. budget.

Burner placement and input is analyzed to provide maximum melt target coverage, ensuring fast and efficient melting. Burner specifics such as flame length, shape, and velocity are considered to maximize melting performance without compromising metal quality.

The cost of improper burner assessment and placement can lead to direct flame impingement and excessive bath surface agitation, causing high metal loss. Over-sized heat input into the furnace chamber can dramatically reduce the service life of the valuable furnace lining.

Refractory Lining

SECO/WARWICK understands that your process and operating parameters require a furnace refractory lining and materials specifically designed to suit your operation. The factors taken into consideration include composition of your alloy, the aluminum freeze plane, spall resistance, metal attack resistance, and abrasion resistance in severe duty areas, and your charging, fluxing and cleaning routine.

New energy saving refractory materials such as calcium silicate board, which is a non-wetting board with superior insulating properties, are constantly being evaluated and utilized to provide efficient and economical furnace lining designs. Materials such as this become a cost effective back up material in the value calculation.

Other Products

You may be interested in

Post requirements