Powder Coating

By: SEVEN STARS CONTRACTING AND AL NEJOUM AL SABAA METAL COATING| Price | Available on request |

| Category | Aluminium Surface Treatment Services |

| Manufacturer | NA (Service Provider) |

| Min Order Quantity | 1.00 Unit |

| Delivery Lead Time | As per order |

| Place of Origin | UAE |

| Supply Ability | NA |

| Packaging Details | NA |

| Transportation Details | NA |

Description

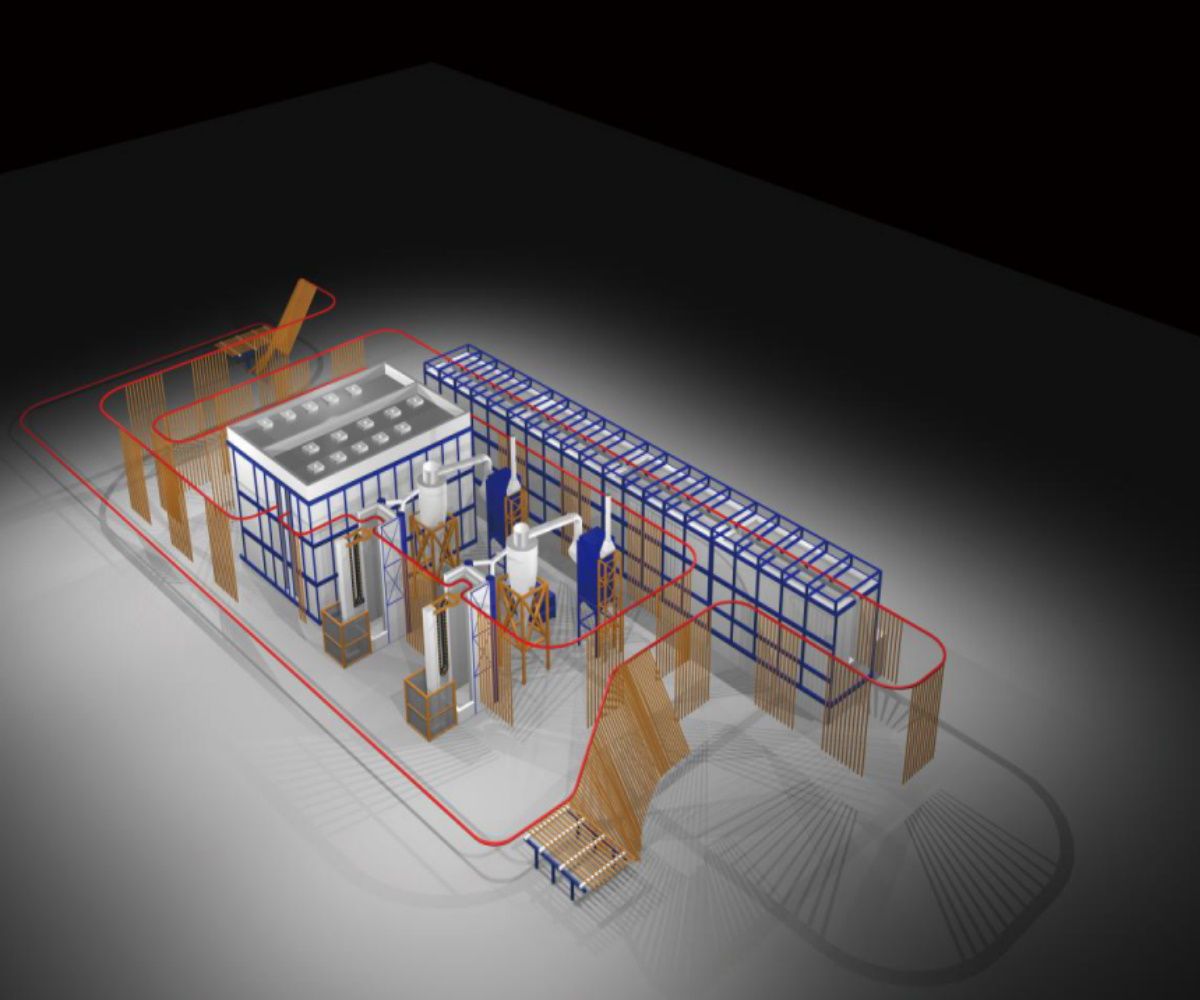

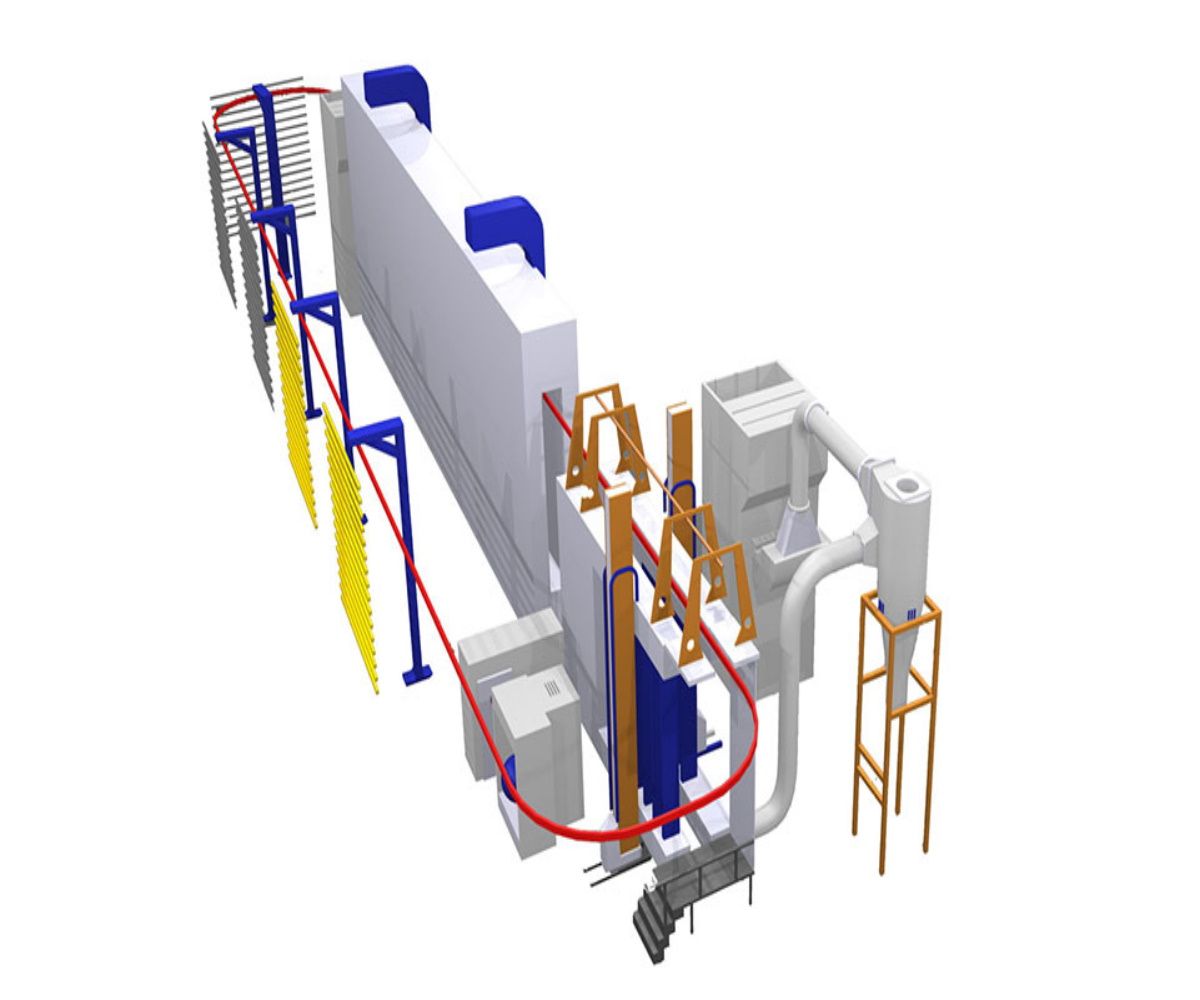

1. Powder Coating

Powder coating is the application of a dry paint in the form of a powder onto a surface using the principle of electrostatic charging. Powder may be a thermoplastic or a thermoset polymer. It is usually used to create a hard finish that is tougher than conventional paint. After the application process the paint is cured under heat to allow it to flow and form a “skin”.

Before applying the finish, the chosen part must either chemically or mechanically cleaned, removing dirt, oils, old, finishes, and oxidation. Poor surface preparation results in powder coating problems, which is because of impurities and poor adhesion between the powder and the metal base.

Al Nejoum Al Sabaa Metal Coating uses several cleaning methods for powder coat prep depending on size, material, cleanliness, etc. Because we do so many metal finishes in house we have cleaning methods for any metal at our disposal. Our main method utilizes a phosphate coating followed by a quick dry in the oven for Ferrous or Iron based items or an etching, degreasing combination with chromate conversion process for aluminum.

In the application process, the polymer paint powder is applied from an air-powered gun. As the powder leaves the gun, it is given a positive electric charge while the part is grounded, giving it a negative charge. The powder flows and “sticks” to the grounded surface due to the attraction of the dissimilar charges. Where regular paint will over spray, causing waste and mess, powder wants to attach itself to the grounded part as much as it can. This causes a significant reduction in wastage.

After the part is fully coated, it is placed in an oven at 200-210 C .

Time and temperature vary according to types of polymers and part mass.

We carry a variety of powders for materials in a variety of applications. If we don’t have it in stock, we’ll track it down for you. If you don’t know what kind of powder would be best to use for your project, we can help find it for you.

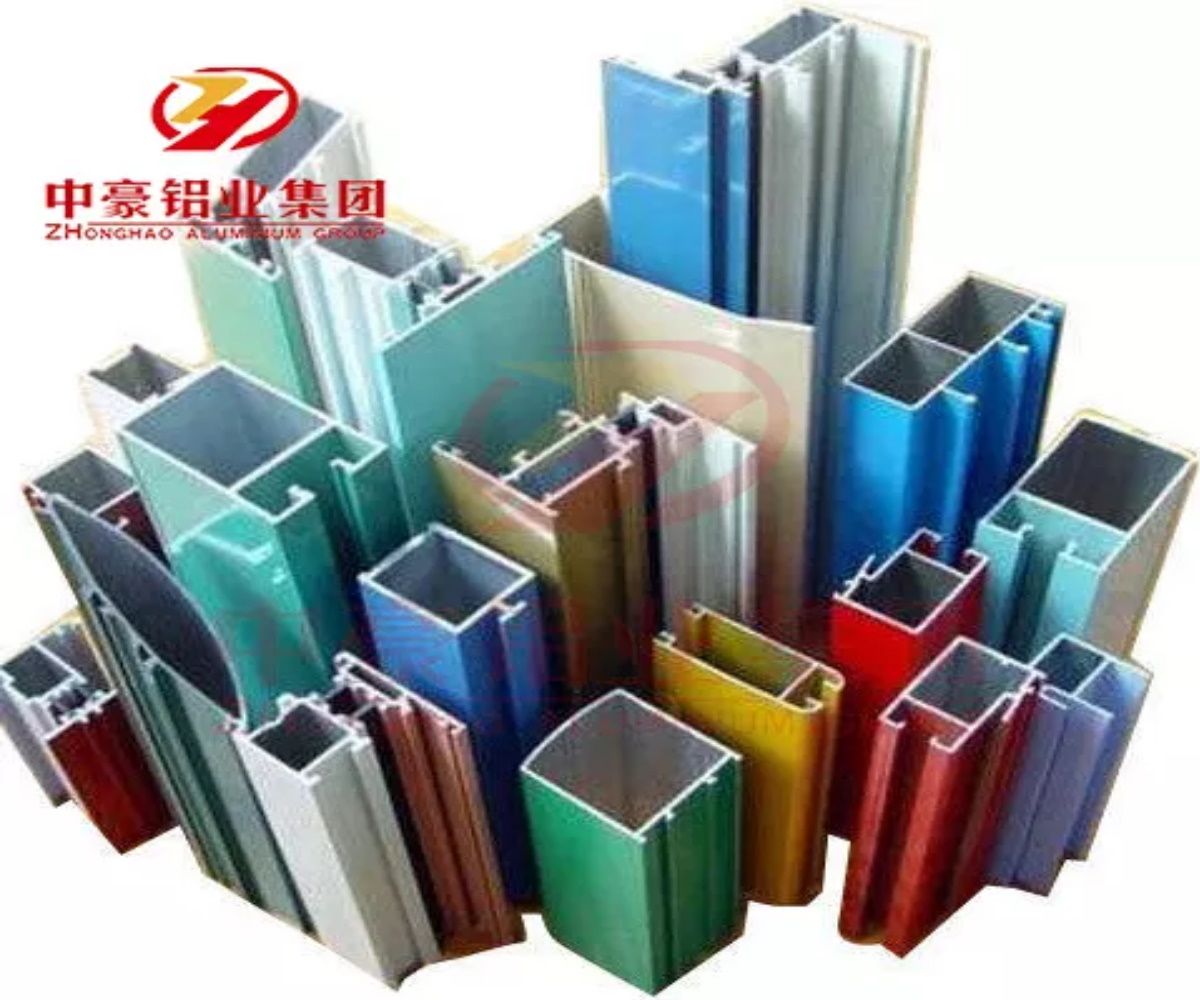

2. Silver Chrome Powder Coating

As the name suggests, chrome silver powder coating is a technique that involves the application of fine silver particles over a given object or surface. While the exact process varies depending on the manufacturer, powder coating is typically applied by projecting the silver powder particles towards the fixture using a standard spray. However, what makes powder coating different is that it integrates the uses an electrostatic charge to accelerate the rate at which the silver powder particles are projected; thus, resulting in a cleaner and more efficient workpiece.

After the silver powder particles have been projected on the fixture, the fixture is cured under to heat. This allows the coating to form a skin-like layer on top, as well as an attractive mattee or flat finish, adding further aesthetic value to the fixture.

3. Zinc Powder Coating

Epoxy powder coating is a very durable thermoplastic coating most often applied on steel items. A Zinc primer powder coating is done as a base coat followed by a top coat of Epoxy powder coating. This type of coating ensures a very highly durable weather resistant finish for outdoor applications. We use a special product called Abcite from AXALTA(Dupont) which has excellent performance is hot and humid environments.

As an environmentally friendly company we also have a zinc free prime alternative which can also be used a very good base coat.

4. Antique Bronze Finish Powder Coating | Antique Brass Finish

Antique Bronze Finish powder coating is one of Al Nejoum Al Sabaa Metal Coating exclusive specialties. This particular finish comes in gold, copper, silver, red and bronze colors. The rustic look offered by this finish is very unique and is ideal for garden furniture, gates, fences, vases and entrance doors. Contact us for Antique Brass Finish Powder Coating services

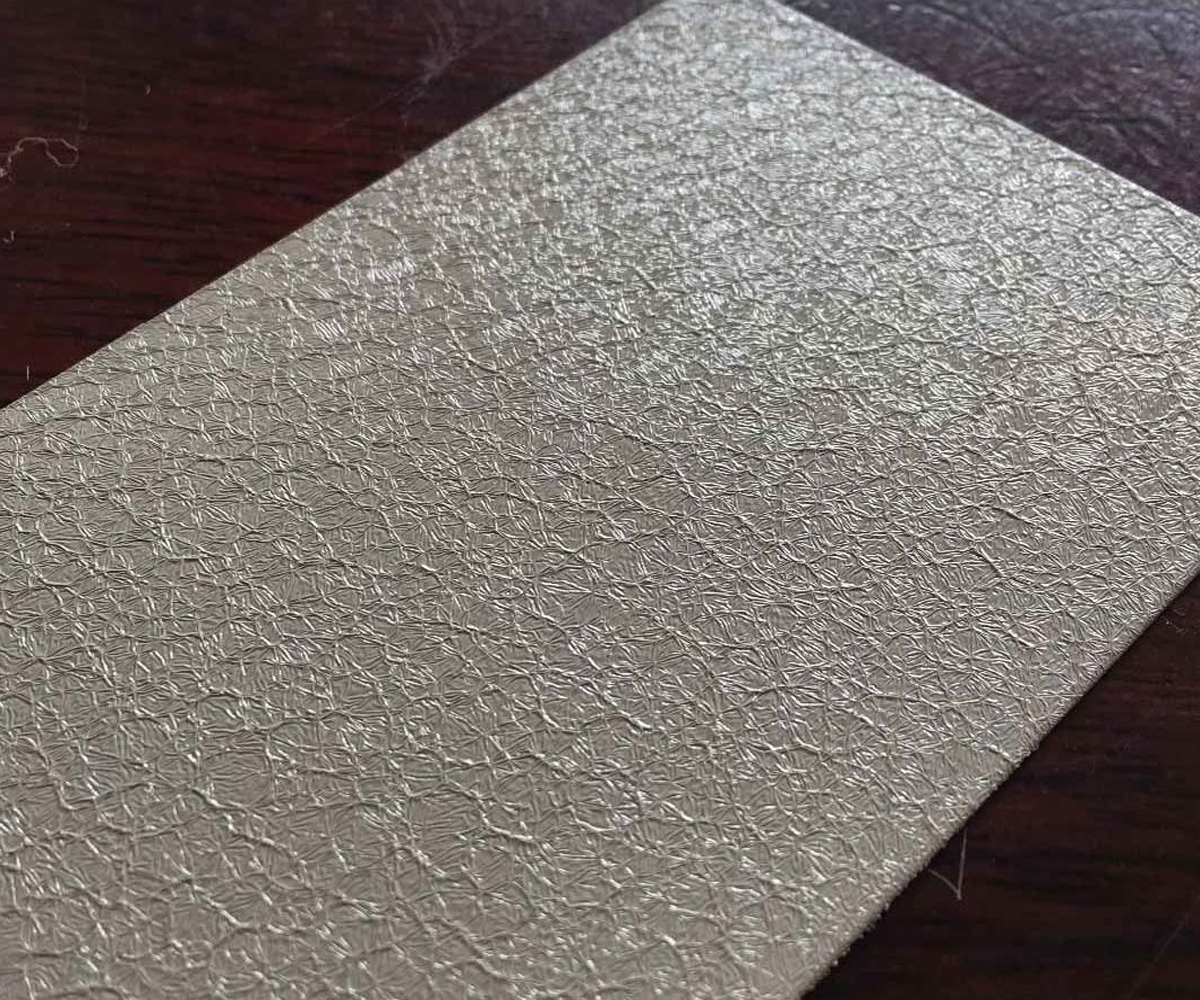

5. Special Effect Powder Coating | Leather Effect Powder Coating

Al Nejoum Al Sabaa Metal Coating always adds new varieties of finishes and textures to its ever-growing portfolio. We have a special R&D team to formulate different textures and develop colors that are exclusively made to order for special requirements as per customer specifications. Contact us for Special Effect Powder Coating.

We are the only facility to offer leather effect powder coatings across U.A.E. This powder finish is made specially for indoor applications to be used on speciality furniture, wardrobes and wall claddings.

They bring any living space alive with a unique texture. The black leather and the desert sand leather colors are the most sought after among other colors like teal , aquamarine, slate and burgundy. Contact us for Special Effect Powder Coating.

You may be interested in

Post requirements