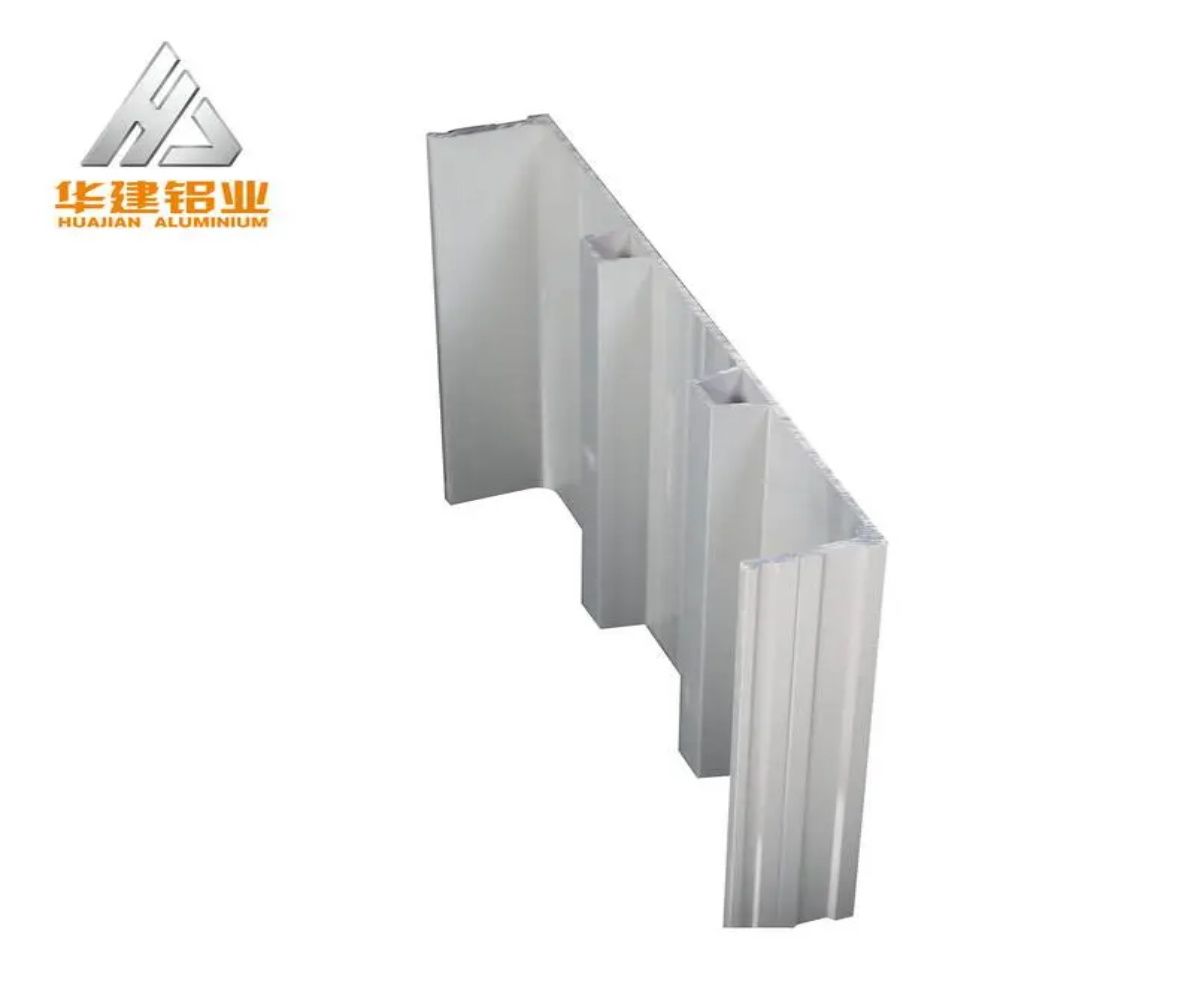

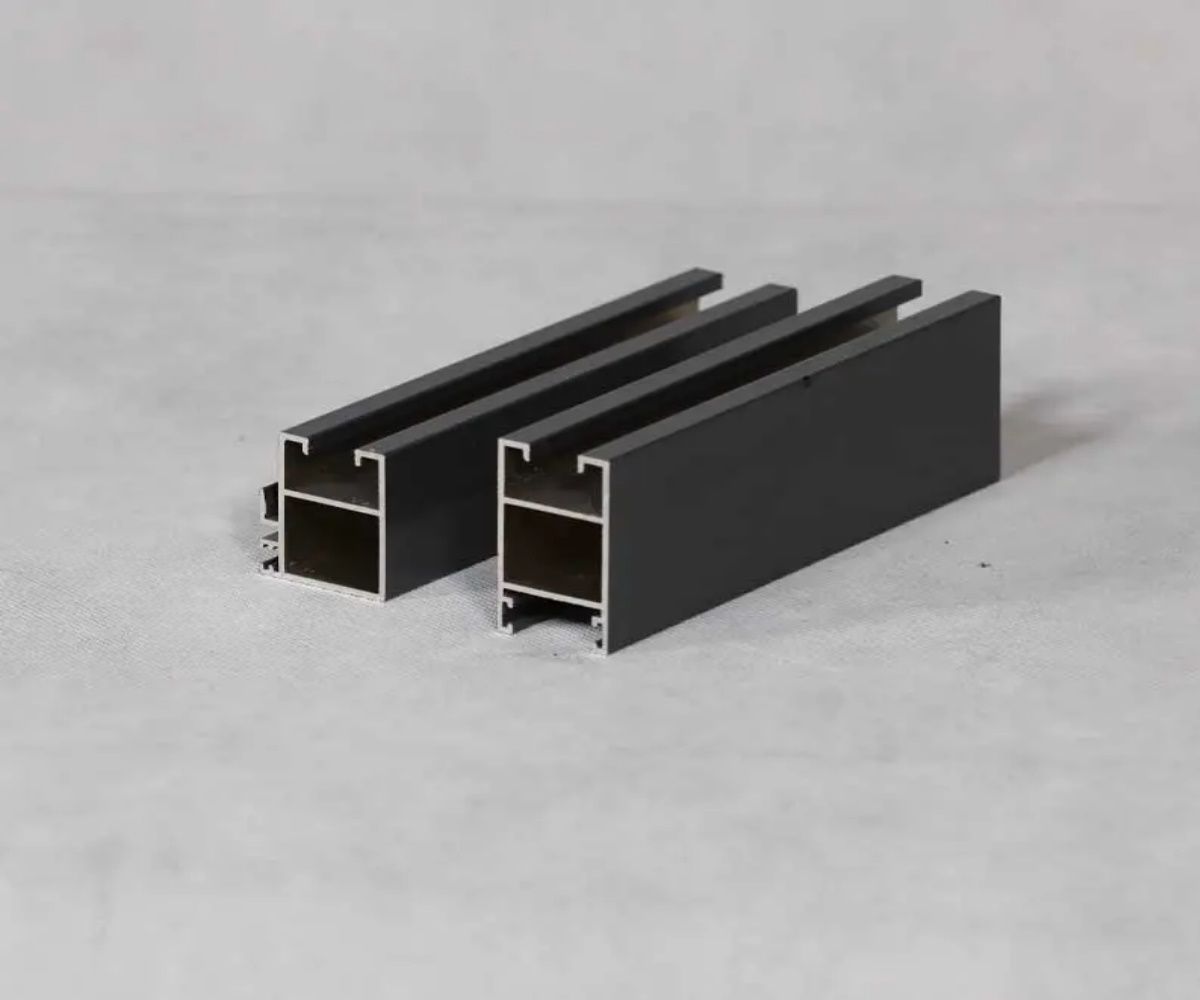

Aluminium Form Work Plate

By: SHANDONG HUAJIAN ALUMINIUM CO.,LTD| Price | Available on request |

| Category | Structural and Support Systems |

| Manufacturer | Shandong Huajian Aluminium Co.,Ltd |

| Min Order Quantity | 2.00 Tons |

| Delivery Lead Time | As per Order |

| Place of Origin | China |

| Supply Ability | Customization on Requirement |

| Packaging Details | Standard Export Packing |

| Transportation Details | Road/Ship |

Description

As a new building formwork in recent years, building aluminum formwork can be seen in more and more developed countries in the world, it is superior to the traditional template in material, construction effect, cost budget, service life, environmental protection and so on. At the same time, it can reduce the cost of the project, improve the engineering quality, speed up the construction period and avoid human error in the construction process, after the removal of the board without the residual engineering waste, to provide a safe and civilized working environment for the construction workers.

The aluminum alloy template has the characteristics of light weight, flexible disassembly, high rigidity, long service life, large plate surface, low slits, high precision, smooth and smooth pouring cement, low reliance on machinery for construction, low cost of labor and materials, wide application range, low maintenance cost, high construction efficiency and high recovery value.

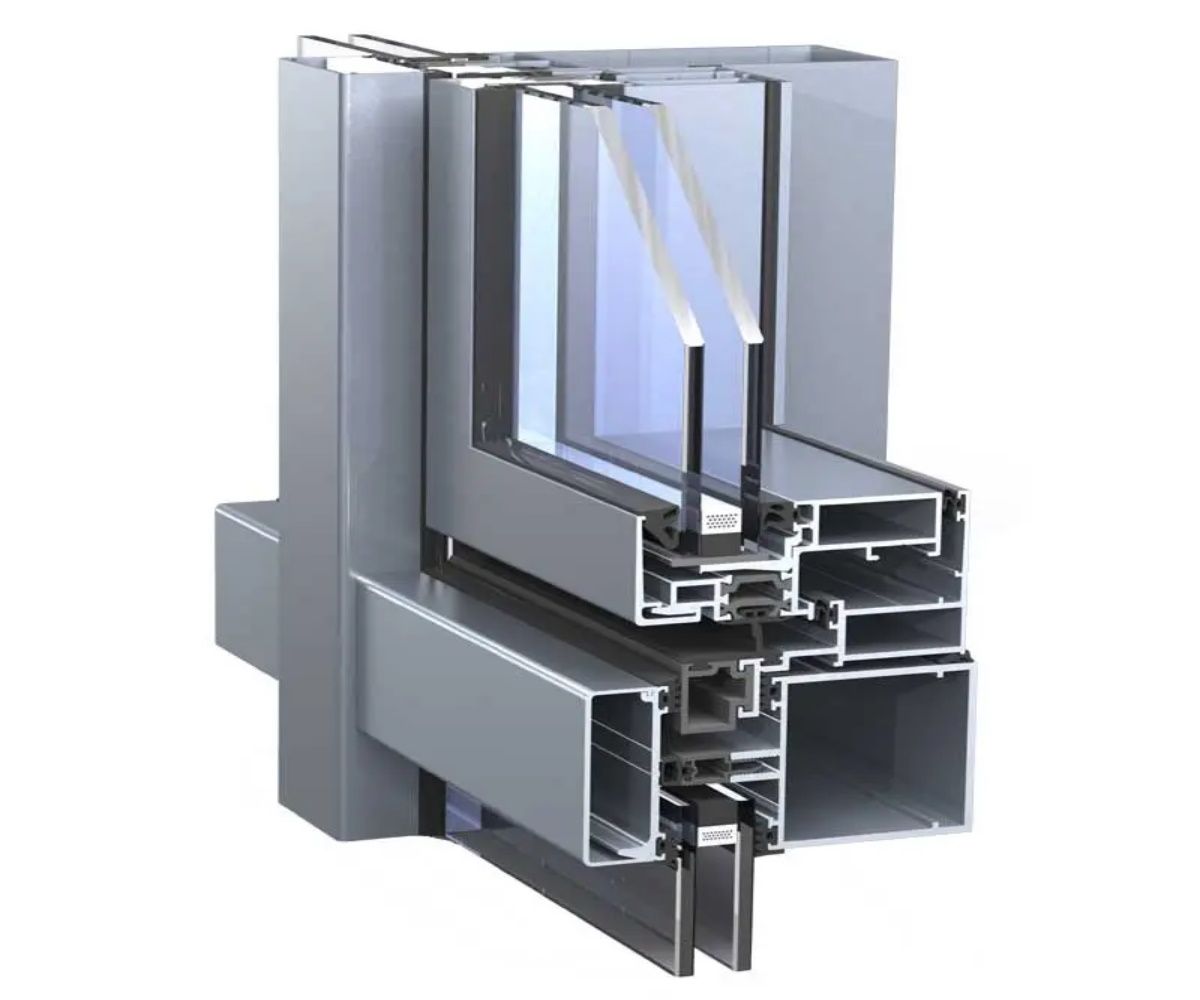

The product can be designed and processed according to the design drawings of the building projects made by customers. The distance between the plates can be adjusted by the tension bar, and the holes on the edge of the template are distributed according to a certain spacing. The connections are mainly cylindrical inserts and wedge-shaped inserts. The support behind the template can be supported by a diagonal or square as a backrest for ease and practicality.

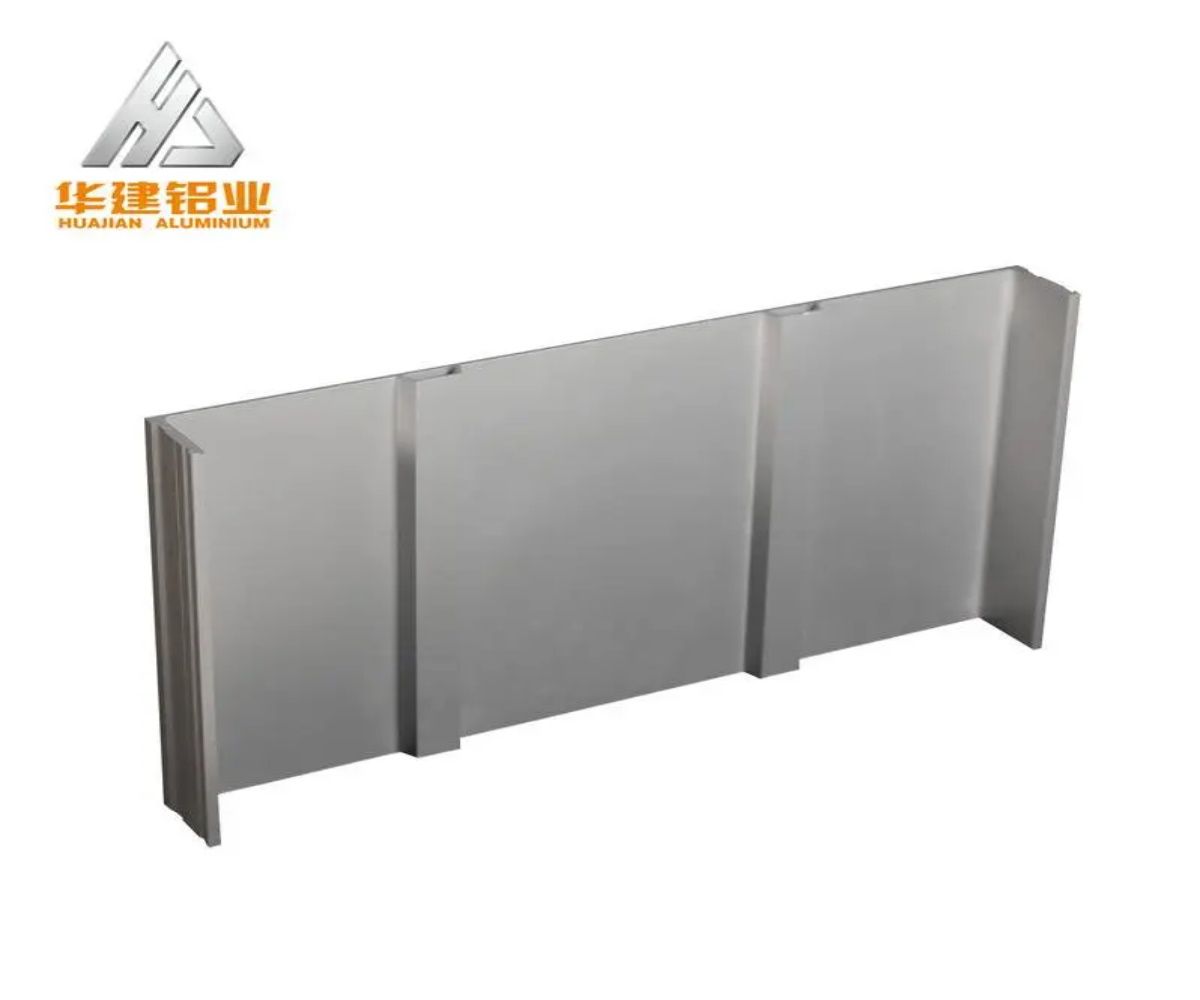

The aluminum alloy building formwork is suitable for the use of templates such as wall formwork, horizontal floor, column, Beam, crawler and bridge formwork. It can be made into a small, medium, or large template. The weight of the product is light, can be all-man-made, can also be formed after mechanical hoisting. The main connection is a wedge pin connection, and construction usually requires only a wrench or a small hammer, convenient and quick. Before installation, it is only necessary to train the construction personnel simply. No matter how to use the aluminum formwork system, the basic methods and components are the same, the builders are able to skillfully use; the precision of the template is high, it also saves on Secondary Plaster and labor costs, and gives the building a higher Factor of safety of quality.

The Aluminum Alloy building template has higher recovery value and lower cost-sharing. With more than ten years of history in advanced countries and regions, it is becoming more and more popular nowadays. Because of its obvious advantages, it is also renewable energy. It has responded to the call of "four sections and one environmental protection" , which is the direction of future development.

Top 10 advantages of aluminum formwork.

1.Advantages of the aluminum formwork is that it is highly efficient and has a short period of time: the Aluminum Alloy Building formwork system is a rapid die-breaking system. It can be removed in 18-36 hours, so a single layer of aluminum template and three single layers can be used, normal construction can reach 4-5 days, which can shorten the construction period greatly, save management cost for the construction unit and shorten the development period for real estate developers.

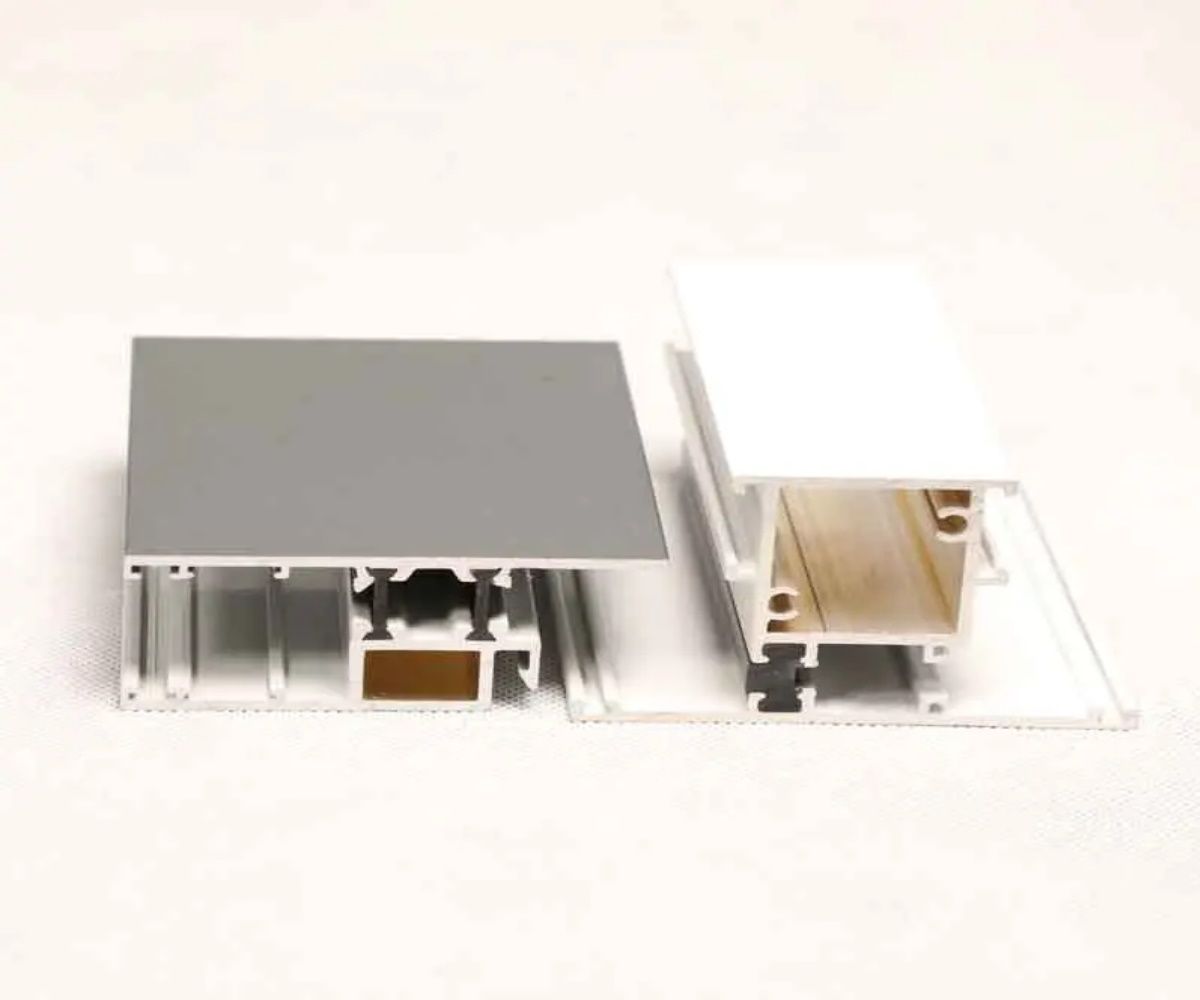

2.Low cost of reusable: all parts of the aluminum formwork system can be reused, and the aluminum alloy template system is made of Aluminium Alloy extrusion material (6061-T6) , a set of template specifications for the construction can be used over 300 times, the cost of use is low.

3.Advantages of aluminium templates: easy construction, high efficiency: The aluminum template system is simple to assemble, convenient, and installed only by increasing the standard plate proportionally. The weight of the aluminium formwork is 18-25 kg per square metre, the construction process is fully assembled and transported by hand and does not rely on lifting machinery (workers usually only need a wrench or a small hammer, convenient and quick) , the installer can install 20-30 square meters per person per day (aluminium template installers save 30 per cent compared to the wooden template and do not require a mechanic, with a simple one-hour pre-installation training for the construction crew).

4. High stability and high bearing capacity: All Aluminium formwork systems are assembled from aluminum plates, and when the system is assembled, a whole frame is formed, the stability is good, the bearing capacity can reach 60KN per square meter, there won't be an increase accident.

5. The aluminum formwork system is applicable to all construction components, such as load-bearing walls, columns, beams, floor slabs, staircases, balconies and so on, can be made of concrete.

6.After removing the mold, the concrete has good surface effect: After the aluminum template is removed, the surface quality of the concrete is smooth and clean, which can meet the requirements of surface and clear water concrete, and can save the cost of dusting twice.

7.The site does not produce construction waste, construction is safer: all parts of the aluminum template can be reused, there is no waste, no rust, no fire hidden danger, no iron nail on the installation site, residual wood-wood marketing and other construction sundries left over from the Sawdust, the construction site is clean and will not produce large amounts of construction waste, like the use of wooden formwork, to achieve full compliance with green building construction standards, through the adoption of light panels, ensure that the construction crew can work safely on the panel.

8.Design one-time molding, high precision and high practicability: to ensure the overall strength and service life of the building according to the construction drawings, one-time design, the whole casting, the small precision of the construction error and the overall strength and service life of the building, suitable for high-rise, super-high-rise buildings and multiple condominium buildings, the aluminum template can be assembled in different sizes according to the project, and the used template can be used to build new buildings, just replace about 20 percent of the Non Standard Board.

9.High recovery rate and high residual value: Aluminium Alloy materials can be recycled all the time, and when the aluminum template system is scrapped, the residual value of waste treatment is high. All Materials of aluminium templates are renewable materials, in line with the State's regulations on energy conservation, environmental protection, low carbon and emission reduction for construction projects, and the industrial policy of sustainable development.

10. The advantages of the aluminum template) the support system is small and easy to walk: In traditional construction methods, the construction technology of floor slabs and platforms is generally supported by full-floor scaffolds. The bottom support system of aluminum alloy is supported by "single-tube vertical independent" , with an average distance of 1.2 m. it does not need to be supported by transverse or oblique pull, the operation space is large, the construction personnel passes, the material is transported freely, the removal of the single support is easy and convenient, easy to manage on site.

Other Products

Post requirements