Online Degassing and Filtration Equipment

By: Shandong Jinyi New Material Co., Ltd.| Price | Available on request |

| Category | Equipment |

| Manufacturer | Shandong Jinyi New Material Co., Ltd. |

| Min Order Quantity | 1.00 Unit |

| Delivery Lead Time | 30 Day |

| Price | 1.00 |

| Place of Origin | China |

| Supply Ability | 1000 |

| Packaging Details | Standard export packing |

| Transportation Details | Ship |

Description

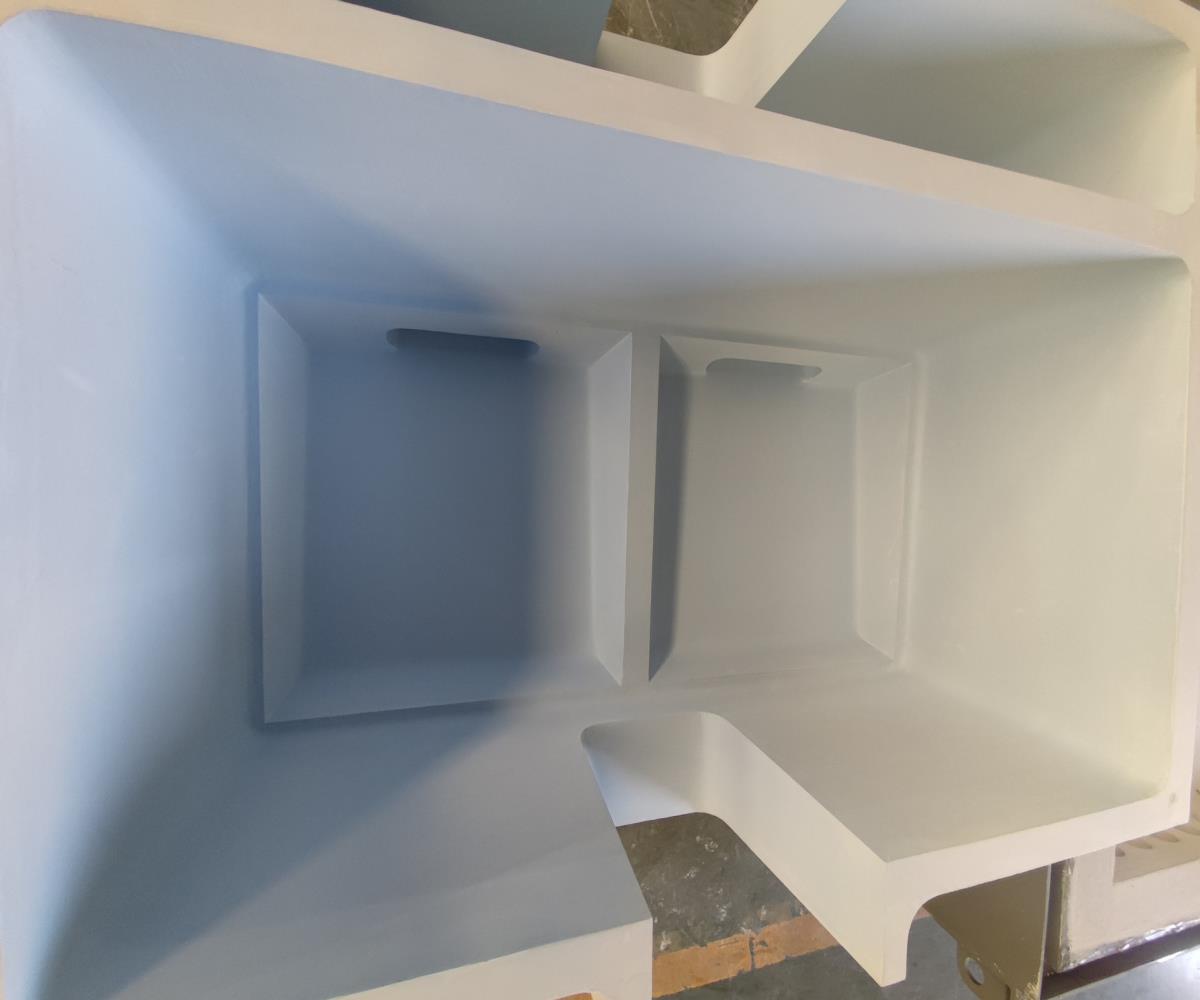

The online degassing unit adopts advanced high silicon melting technology to get a long service time, degassing rotor, heater protection thimble, and thermocouple protection thimble adopt ceramic manufacturing technology which can meet producing high-precision aluminium requirements. An online degassing unit shall be installed between the furnace and casting equipment. It is used for hydrogen (H) and slags removal from molten aluminium. The online degassing unit has dual functions: processing and heating. It serves high precision molten aluminium purification industry.

Average degassing efficiency is 60%. If using Ar and Mg content ≤1%, the efficiency can reach 0.09cc/100g.The lining is made of high-silicon molten material; the average working life is 2-3 years. It is featured nonstick aluminium, with no contamination. There is a float stopper inside to prevent oxides from being drawn into molten aluminium and the bubbles or slags from running out. Working life is 2-5 years. It performs well in corrosion resistance, heat shock resistance, oxidative resistance, abrasive resistance, and mechanical strength. Shaft diameter 60mm, head diameter 200mm, which shall reduce resistance in stirring. Speed design 450-550 R/M will crush bubbles and disperse them evenly into aluminium. It is cost-effective during long-time usage. It is mainly used for hydrogen (H) and slag removal from molten aluminium.

Other Products

Post requirements