Aluminium Alloy Centralized Melting Furnace

By: Tianjin Hitec Intelligent Equipment Co., Ltd.| Price | Available on request |

| Category | Melting Furnace |

| Manufacturer | Tianjin Hitec Intelligent Equipment Co., Ltd. |

| Min Order Quantity | 1.00 Unit |

| Delivery Lead Time | As per order |

| Place of Origin | China |

| Supply Ability | Customization as required |

| Packaging Details | Standard export packing |

| Transportation Details | Road / Ship |

Description

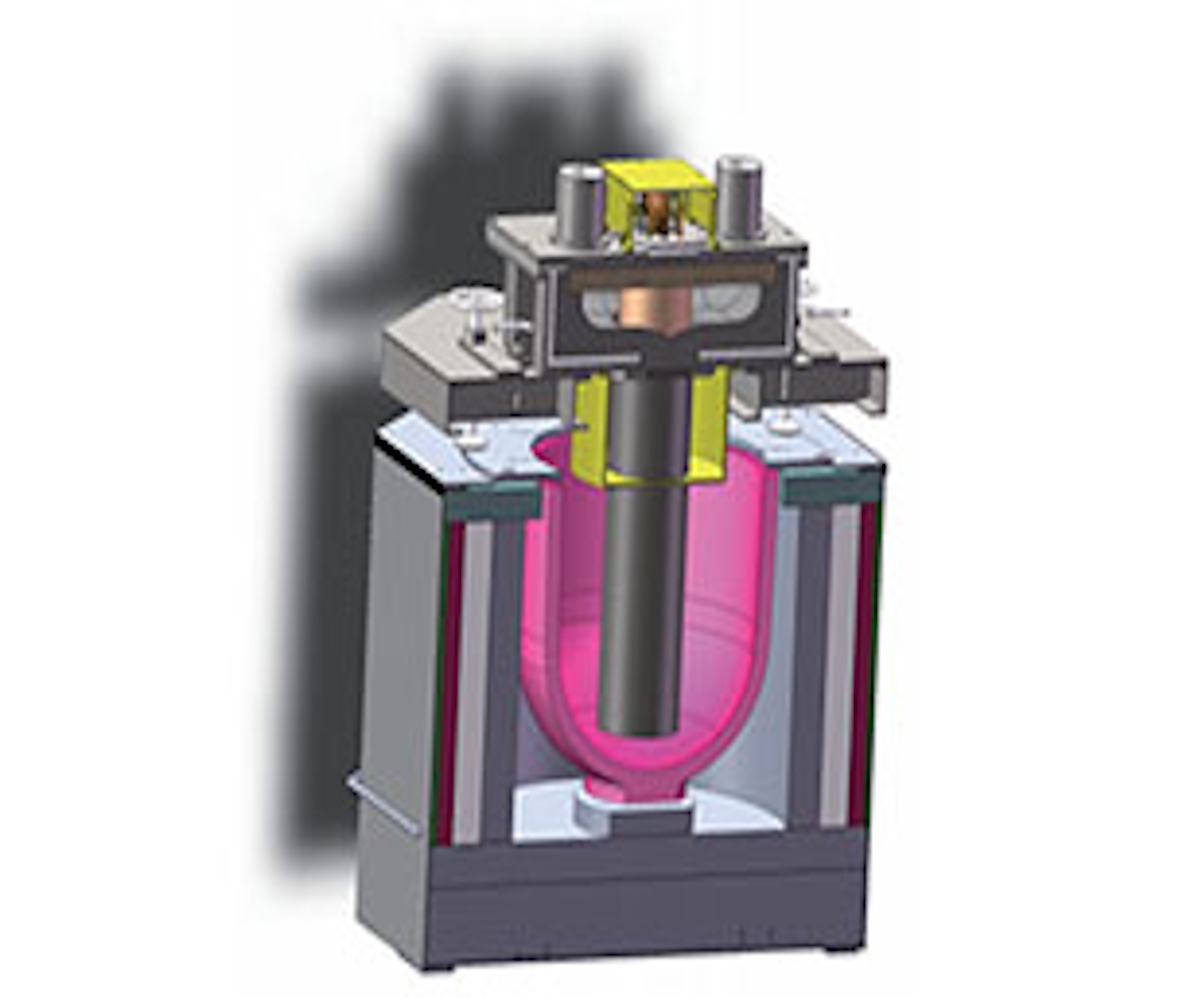

The aluminium alloy centralized melting furnace is a continuous aluminium melting equipment designed and developed by Tianjin Haite combining advanced melting furnace concepts from Japan, Germany and other countries. It has the advantages of high production efficiency, low energy loss and convenient operation.

Equipment Features:

Low Energy Consumption - This type of furnace uses the waste heat of flue gas to heat solid aluminium ingots, effectively utilizing the waste heat. It collects and controls the temperature of multiple points such as flue gas, furnace and aluminium liquid and adjusts the combustion power in a timely manner. The energy consumption is only (60-65)X10Kcal/ton.

Low Aluminium Burning Loss Rate - PLC is used to automatically control the entire combustion process. Combined with the characteristics of aluminium alloy melting and oxidation, the aluminium ingot softens to semi-liquid and semi-solid, and then completely melts. Different power curves are used in each stage of the whole process to heat and melt the aluminium ingot. The aluminium burning loss in the melting process is effectively suppressed, and the melting burning loss rate is no more than 1.5%.

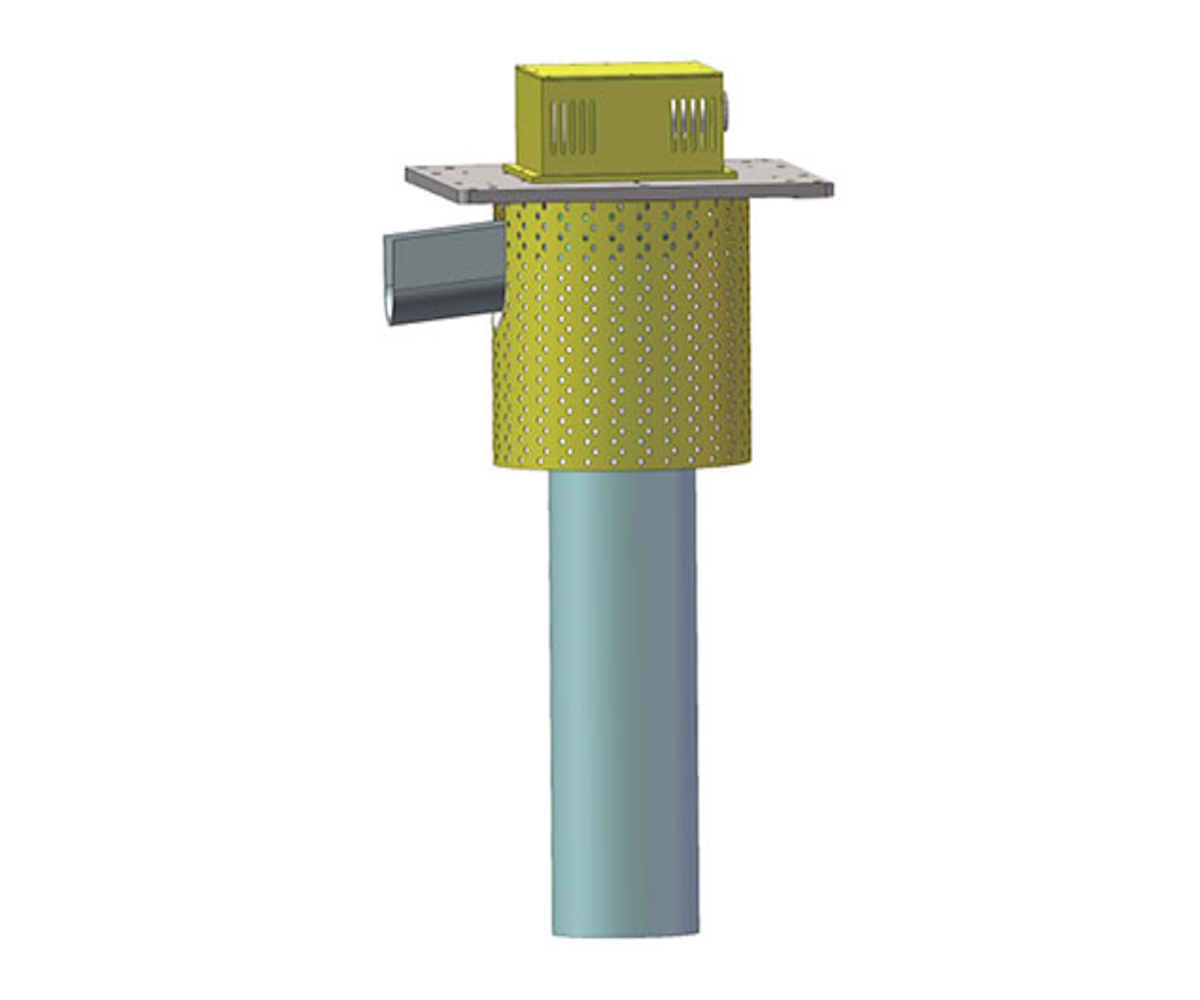

Intelligent, Simple and Reliable Operation - The machine adopts the automatic feeding system for raw materials, which automatically feeds the solid aluminium ingots (and recycled materials) in the feeding tower; it adopts the automatic control of PLC program, with automatic operation, automatic diagnosis, automatic abnormal response and fault alarm in the whole process. The operation is convenient, reliable and safe.

Easy Maintenance - The melting chamber and holding chamber are equipped with slag removal doors (one-touch opening); there is no visual blind spot in the furnace, and slag removal is convenient and labor-saving.

No files available!!

Other Products

Post requirements