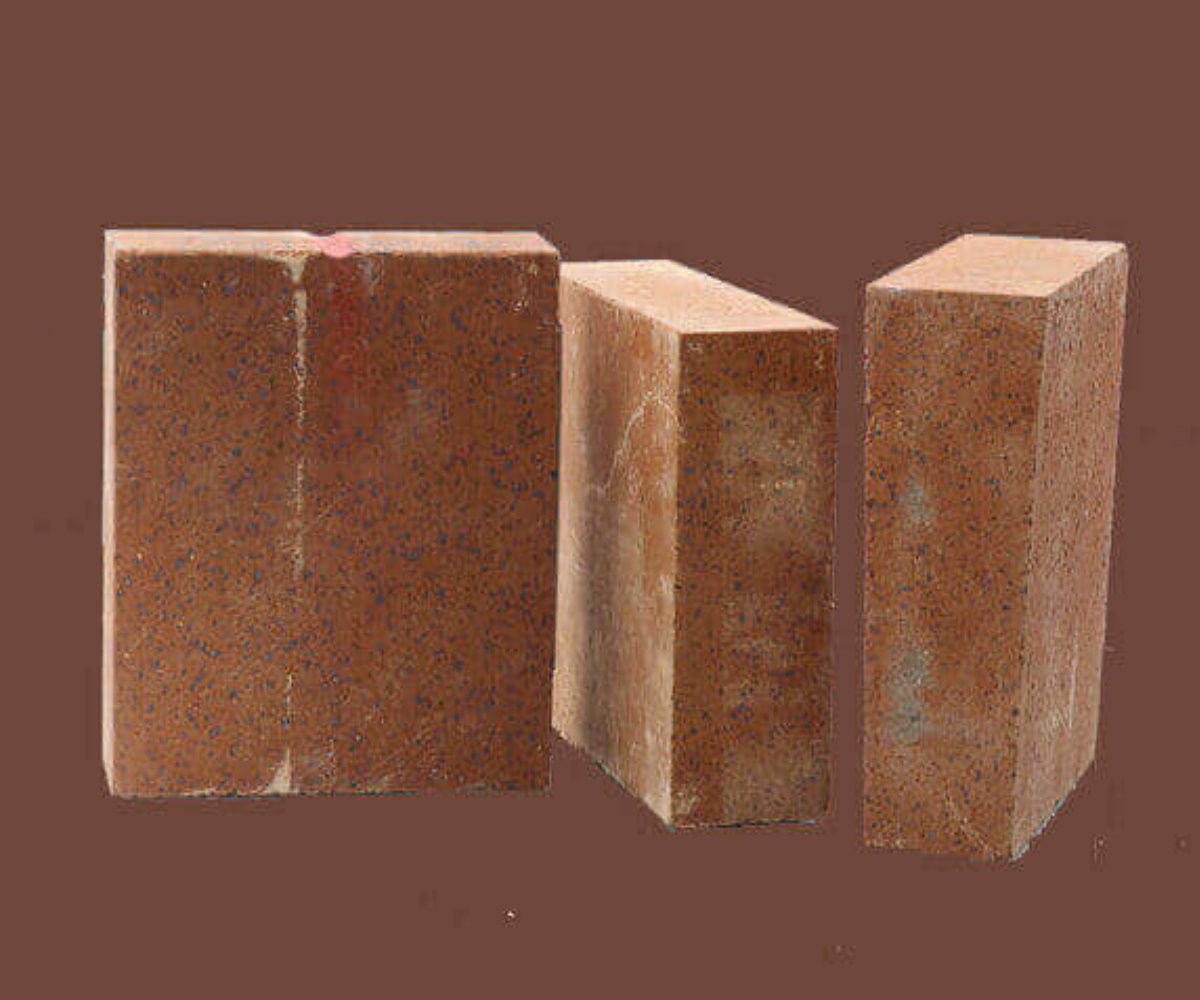

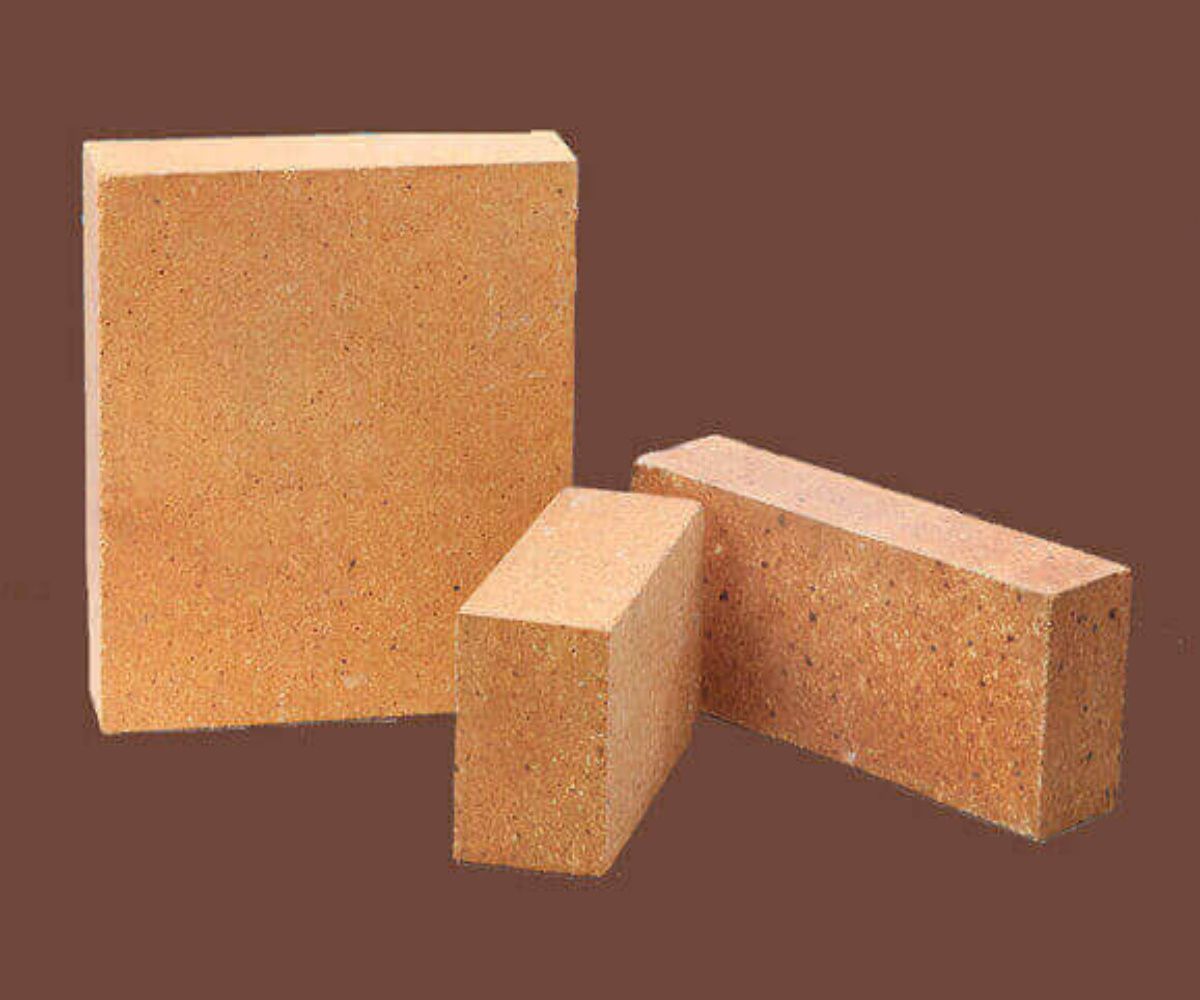

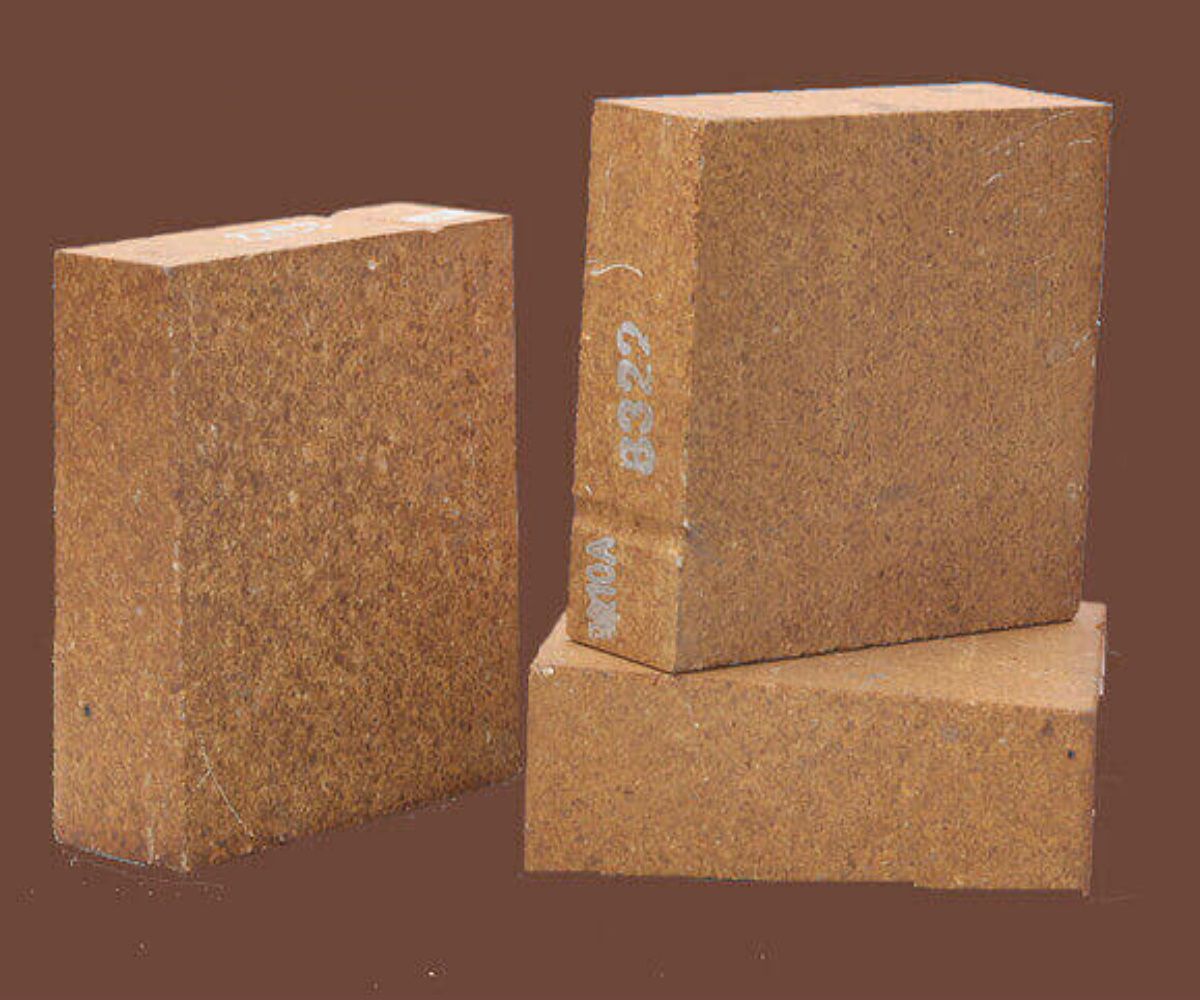

Fire Clay Brick

By: Zhengzhou Caihua Kiln Masonry Installation Co.Ltd| Price | Available on request |

| Category | Refractory Bricks |

| Manufacturer | Zhengzhou Caihua Kiln Masonry Installation Co.Ltd |

| Min Order Quantity | 20.00 Tons |

| Delivery Lead Time | As per Order |

| Place of Origin | China |

| Supply Ability | Customization on Requirement |

| Packaging Details | Standard Export Packing |

| Transportation Details | Road/Ship |

Description

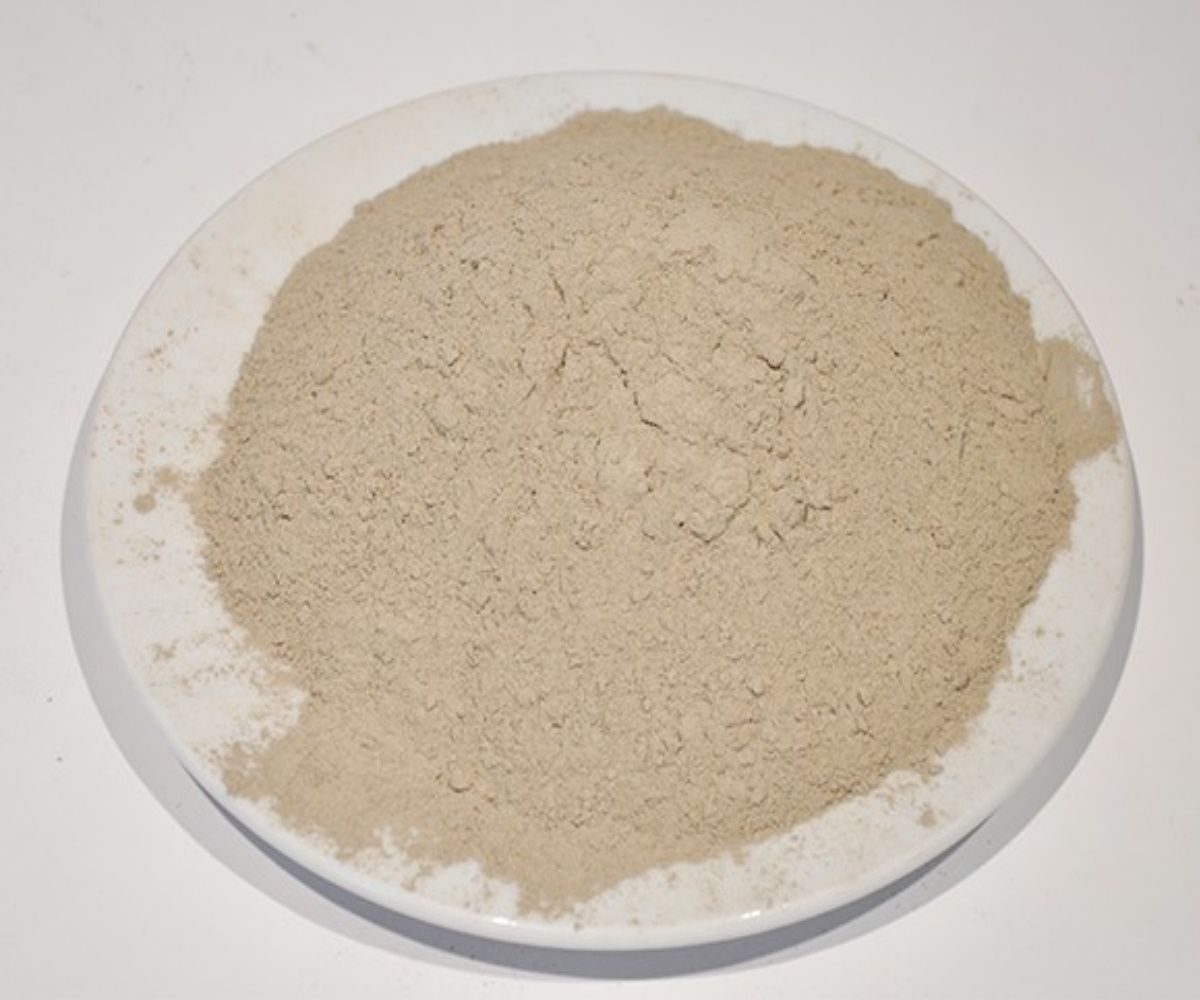

Kiln refractory clay brick is made from clinker clay by mixing, forming, drying, sintering and machine pressing moulding with good resistance to corrosion and abrasion, good thermal shock resistance, good spelling resistance, high mechanical strength, good volume stability under high temperature.

The mineral composition of heavy dense fire clay bricks mainly is kaolinite(Al2O3·2SiO2·2H2O) and 6%~7% impurities (oxides of potassium, sodium, calcium, titanium and iron). The firing process of blast furnace refractory tiles is mainly due to the continuous dehydration of kaolinite to form crystallization of mullite (3Al2O3·2SiO2). SiO2 and Al2O3 in the yellow fire clay bricks form a eutectic low-melting silicate with impurities during the firing process, surrounding the mullite crystal.

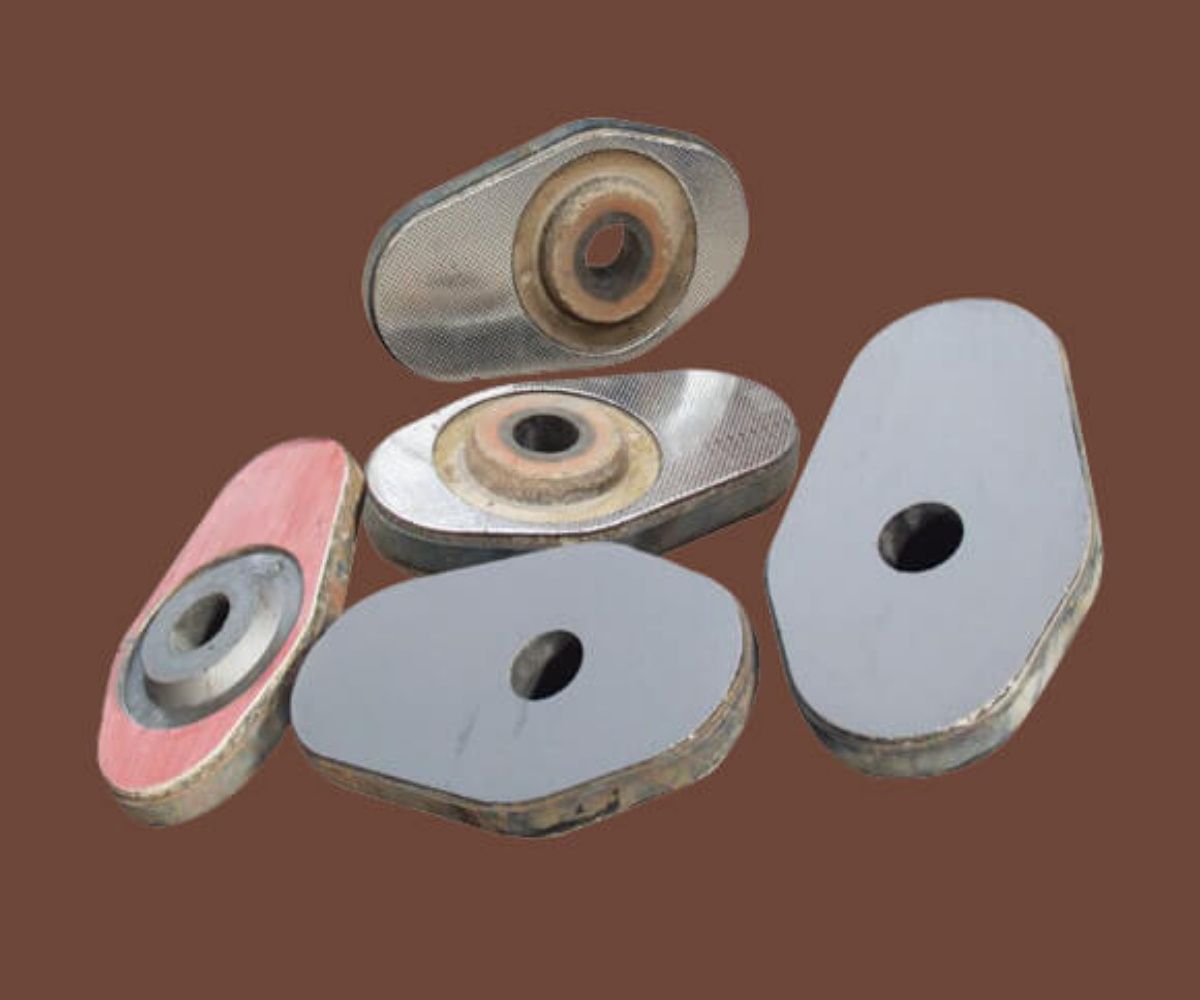

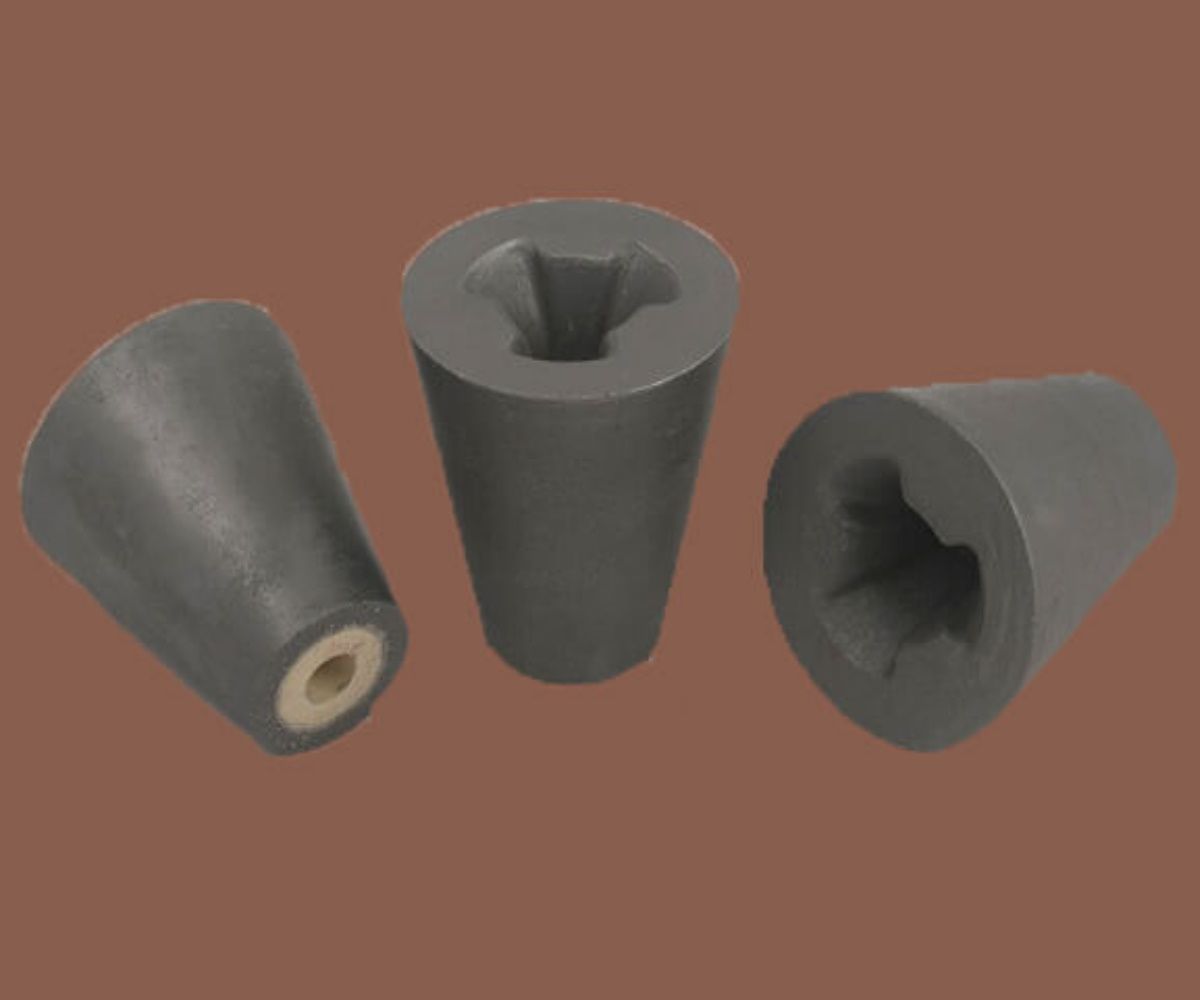

The kiln refractory burner blocks made by CH refractories with various size and free mold charge to meet different kiln applications. To be professional refractory blocks manufacturer since 1984, CH refractories also can design heat resistant bricks for sale, size according to your kiln drawing for free, and suggest you the most economical refractory bricks price for your kiln.

Applications of Clay Brick:

Clay refractory brick plays an incomparable important role in the development of high temperature industrial kiln production, which is the indispensable basic alumina heat resistant material to ensure following production running and technological development.

Clay brick can be applied to

●Machinery and boiler

●Steel and nonferrous metals

●Glass, cement and ceramics

●Light industry and electric power

●War industry and other economic filed

Advantages of CH series Clay Brick:

●Good thermal properties

●Resistant to acid slag and acid gases

●Resistant to rapid cooling and rapid heating

● Customerize mould according to different size requirements for free

●high bulk density,low apparent porosity,low creep,cheapest price in China,Free sample,Free construction guidance ,free 3D design

● Refer attachment for product's parameter & SGS Testing report

Other Products

Post requirements