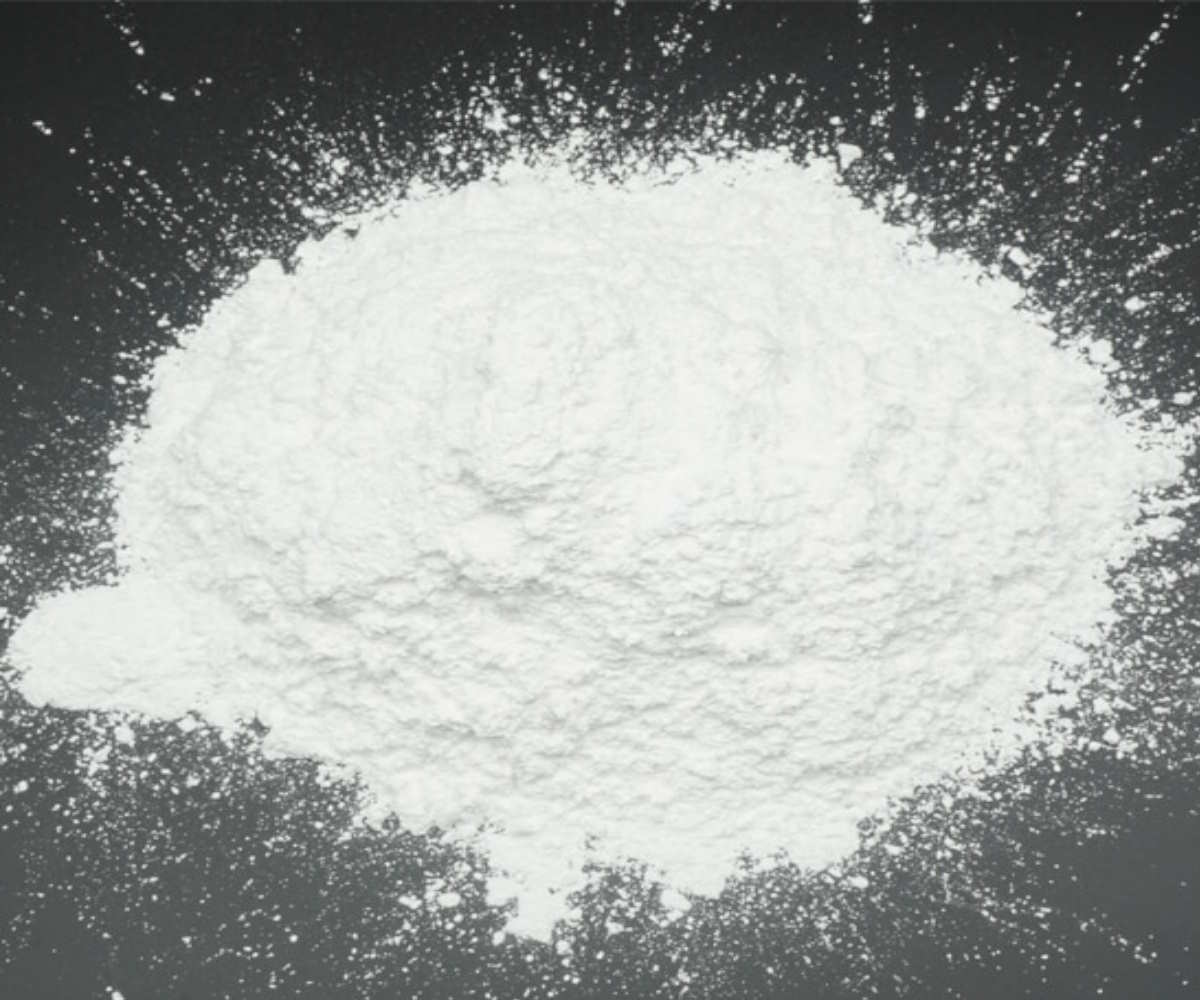

Brown Fused Alumina

By: Zhengzhou Xinli Wear-Resistant Material Co. Ltd.| Price | Available on request |

| Mohs Hardness | 9 |

| Bulk Density | 1.75-1.95g/cm3 |

| Specific Gravity | 3.6-3.9g/cm3 |

| Category | Alumina Products |

| Manufacturer | NA (Trader) |

| Min Order Quantity | 10.00 MT |

| Delivery Lead Time | As per order |

| Place of Origin | China |

| Supply Ability | Customization as required |

| Packaging Details | Standard export packing |

| Transportation Details | Road / Ship |

Description

Brown fused alumina takes the high quality bauxite as the raw material, mixing with iron powder and anthracite, produced by melting in the electric arc furnace at a high temperature over 2000℃. Main chemical compositions are AL2O3, TiO2, and small amount of SiO2 and Fe2O3 etc. Toughness is higher than SiC. The texture is dense, the hardness is high, and the grains appear the spherical shape. It is suitable for manufacturing ceramic and resin high-consolidation abrasive tools, as well as grinding, polishing, sandblasting, precision casting, etc. It can also be used for manufacturing high-grade refractory materials. So the brown fused alumina grain is called as the “Industry Teeth”.

Advantages

- High purity, good crystallization, strong fluidity, low linear expansion coefficient and corrosion resistance

- Brown fused alumina has no explosion, no powdering, no cracking in the application process

- The cost performance is much higher than the traditional brown fused alumina grain. Become the best aggregate and filler for the refractory industry brown fused alumina

- The brown fused alumina grain Can be processed according to user requirements

- Small crystal size, impact resistance

- High purity, dense texture, high bulk density, strong self-sharpening, good toughness, extremely low magnetic content

- The abrasive tools made of brown fused alumina have sharp grinding, low heat generation rate, high grinding ratio, and less adhesion during use. The sintered abrasive tools made have the characteristics of dark blue after firing, no net cracks, and no rust spots. Suitable for manufacturing ceramic and resin high-consolidation abrasive tools, as well as grinding, polishing, etc

Other Products

You may be interested in

Post requirements