Aluminium innovations: Driving efficiency and sustainability in manufacturing

Team AL Circle

2024-05-11

Across industries, from transportation to construction, aluminium is becoming an increasingly important raw material. The aluminium market is estimated to experience a CAGR of 2.06% between 2023 and 20230, while the market valuation will reach USD 2218.93 million. Needless to say, primary and secondary aluminium manufacturing will also peak in the coming years. It has nudged the industry to embrace multi-faceted innovation that is efficient and sustainable. While technology takes the wheel, sustainable practices are also catching up.

Technological innovations that facilitate the aluminium manufacturing process:

Pure metal production: A process innovation

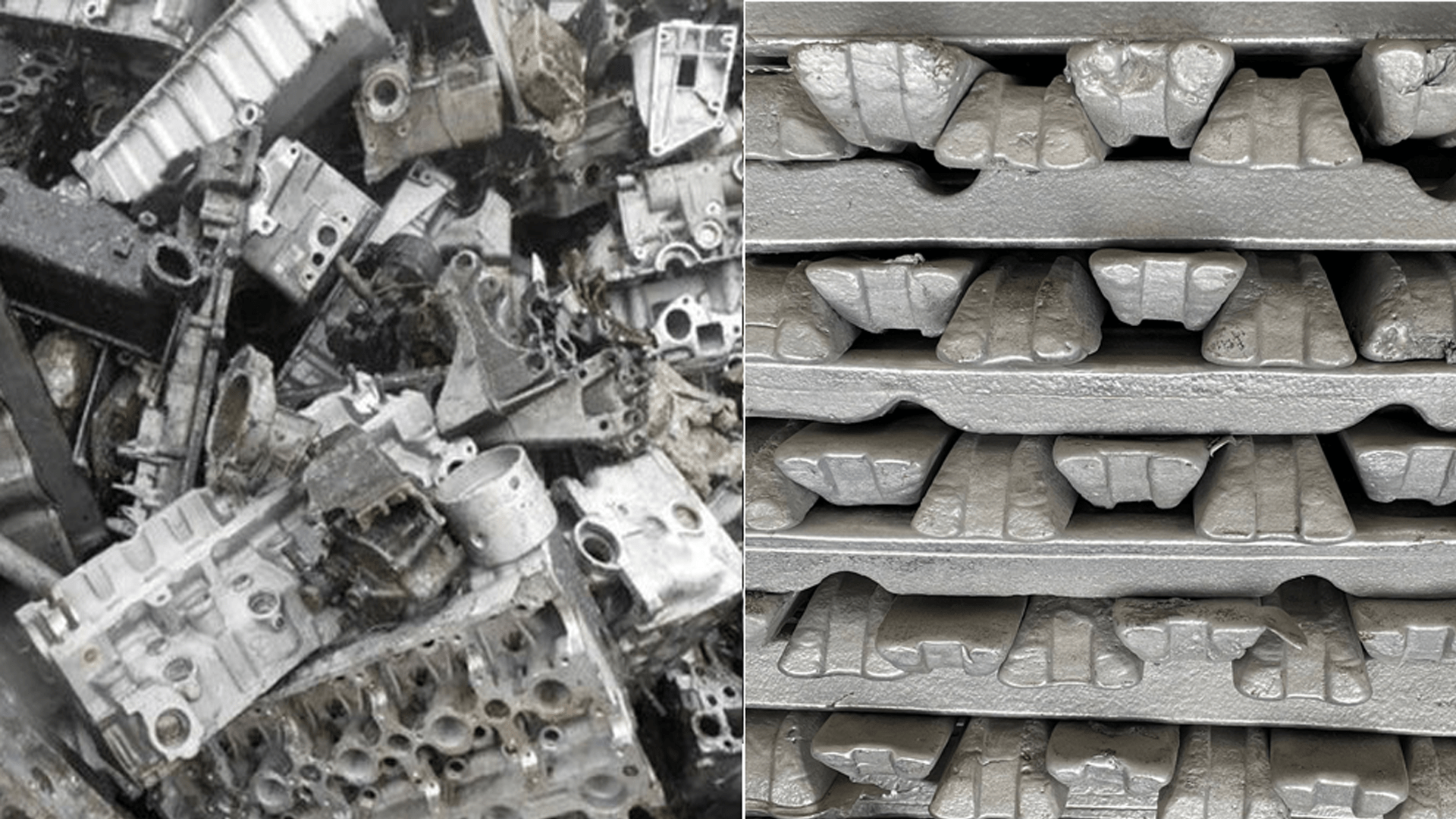

Producing primary aluminium is a resource-intensive process that requires gallons of water and is high-energy intensive. On the other hand, secondary aluminium production requires up to 95% less energy than primary aluminium production. Hence, there is a shifting focus towards secondary aluminium manufacturing. Unfortunately, for a long time, some manufacturers have avoided secondary aluminium because of its lack of purity.

However, the United States Department of Energy-funded project is working towards developing the purest quality of secondary aluminium with little to no level of impurity. The licensed technology will produce a pure form of secondary aluminium that can be used in the transportation industry, which needs lightweight solutions, such as electronic vehicles.

Advancements in surface treatment:

New-age surface treatment methodologies are another notable technological innovation in the aluminium industry. A surface treatment is essential for aluminium products in order to enhance their attractiveness, durability, and corrosion resistance. The eye-catching innovations in this segment include plasma treatments and nano-coating. Plasma treatment effectively removes contaminants and oxides from the surface of aluminium and prepares it for various processes.

In the case of nano-coating, silicone or titanium oxide nanoparticles are used to cover the surface of the metal to make it water-resistant and increase its lifespan. Nano-coating makes aluminium a perfect fit for industries such as aerospace, electrical, marine, construction and automobile.

Technological innovation supports the aluminium industry and facilitates seamless and sustainable manufacturing practices in other industries where aluminium is a primary material.

New-age sustainable practices paving the way for decarbonising the industry

Big corporations, bigger plans

Did you know about the First Mover's Coalition? It is a one-of-a-kind group formed by the members of the World Economic Forum, who use their purchasing power to 'decarbonise the world's heavy- emitting sectors.' Unfortunately, aluminium has been one of these sectors for decades. However, due to rising environmental concerns, decarbonising the industry has become an immediate priority. The First Mover's Coalition has committed to acquiring 10% of aluminium requirements from near-zero emissions processes by 2030.

Alternative energy sources for greener manufacturing processes

The path to carbonisation in the aluminium industry passes through alternative energy sources. Fossil fuel and electric grids are heavy polluters. Moreover, fossil fuel conservation is also a major ecological challenge of the present day. Major players in the aluminium production market, such as Rio Tinto, are conducting a feasibility study with ARENA (Australian Renewable Energy Agency) worth USD 1.2 million to replace natural gas with clean hydrogen as an energy source in one of its aluminium refineries. Similarly, other energy sources such as wind and solar power will also make their way into aluminium refineries through continuous process innovation.

In the end

It is no secret that sustainable urbanisation has recently fueled the growing demand for aluminium and aluminium alloys. Innovative solutions like 3D printing, new aluminium alloys, surface treatment methods and alternative clean energy sources are shaping the future of aluminium for the better. Now it will be interesting to see how the prime actors of the industry ride the wave of innovation and create new opportunities in the aluminium industry.

Categories

Raw Materials

Scrap

Consumables

Primary Aluminium

Secondary Aluminium

Equipment

Technology

Downstream Products

Finished Products

Utilities

Services

Others

Recent Blogs

Subscribe to newsletter

Connect with us