Conveyorised Aluminium Horizontal Coated Powder Machine

By: Foshan Meitu Machinery Equipment Co.,LTD| Price | Available on request |

| Category | Extrusion Finishing Equipment |

| Manufacturer | Foshan Meitu Machinery Equipment Co., Ltd. |

| Min Order Quantity | 1.00 Unit |

| Delivery Lead Time | As per order |

| Place of Origin | China |

| Supply Ability | Customization as required |

| Packaging Details | Standard export packing |

| Transportation Details | Road / Ship |

Description

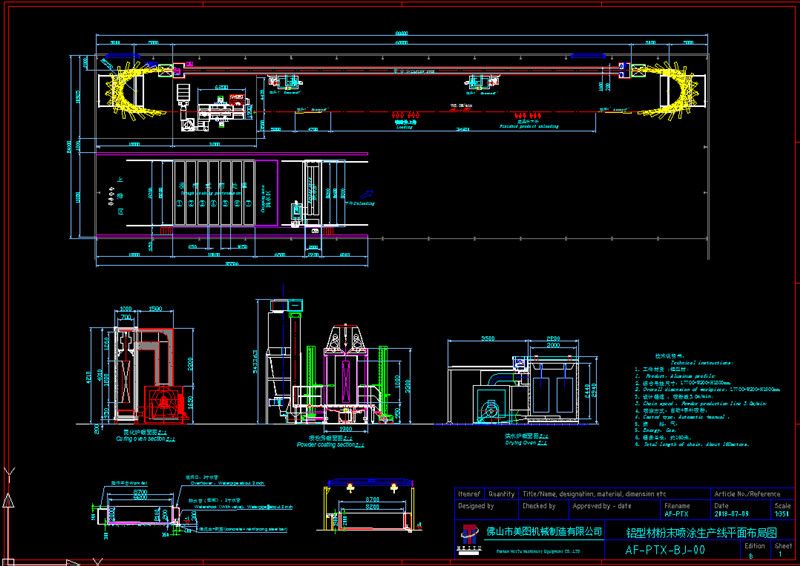

Aluminium coated powder machine factory consists of:

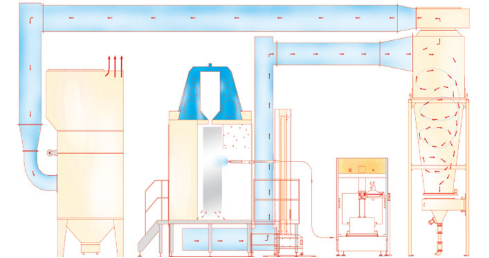

Dipping tanks pretreatment, crane system, dipping area. PVC anticorrosion system, drying oven, powder spraying chamber and recycle system, oven, electric control system, the magic rapid colour changing center, hanger beam.

Quality Compliance:

- Council LVD directive 2014/35/EU

- Machinery Directive 2006/42/EC

- EMC directive 2014/30EU

- ISO12100:2010

Overhead conveyor coating powder machine Features and Advantages:

Sandwich structure PP board powder coating booth

1. The powder booth is arranged in a partition work shield room, and the dusting room body is a closed space for the powder spraying operation of the workpiece.

2. The structure and airflow design of the powder booth are very important for powder coating

3. Combined with the production line workpiece process requirements, the powder booth has the following characteristics:

- Overall size of powder room:6.7*1.9*3.3m(length × width × height)overall size of powder room:6.7*1.9*3.3m(L*W*H)

- Each side of the automatic spraying room is provided with 6 automatic spraying guns, and the automatic guns are spread across; the front and back ends of the automatic dusting chamber are provided with an external manual spraying operation platform, which is convenient for the inspection and repair of workpiece surface quality.

- The dusting chamber adopts a double-layer composite sandwich structure. The engineering plastic is imported from Germany. The thickness of the engineering plastic plate is 6mm, and the thickness of the sandwich is 120mm.

- The surface of the chamber is smooth and smooth, and the joint between the plates is filled with imported "Sika" non-silicon sealant, and there is no leakage of powder.

- Engineering plastic anti-static, not easy to absorb powder, powder change color operation is easy.

- The inlet and outlet of the powder booth is set with an ear canal, which can minimize the opening area of the dusting room while ensuring the smooth entry and exit of the workpiece, and the appearance is beautiful, and effectively prevent powder spillover.

- Quick-change explosion-proof solar lamps are installed at the powder coating booth roof and hand repair door to ensure adequate lighting in the duster room.

- All gas pipes are connected by quick joints, easy disassembly and assembly and fast color change speed.

Other Products

Post requirements