Automatic Aluminium Vertical Coated Powder Line

By: Foshan Meitu Machinery Equipment Co.,LTD| Price | Available on request |

| Category | Extrusion Finishing Equipment |

| Manufacturer | Foshan Meitu Machinery Equipment Co., Ltd. |

| Min Order Quantity | 1.00 Unit |

| Delivery Lead Time | As per order |

| Place of Origin | China |

| Supply Ability | Customization as required |

| Packaging Details | Standard export packing |

| Transportation Details | Road / Ship |

Description

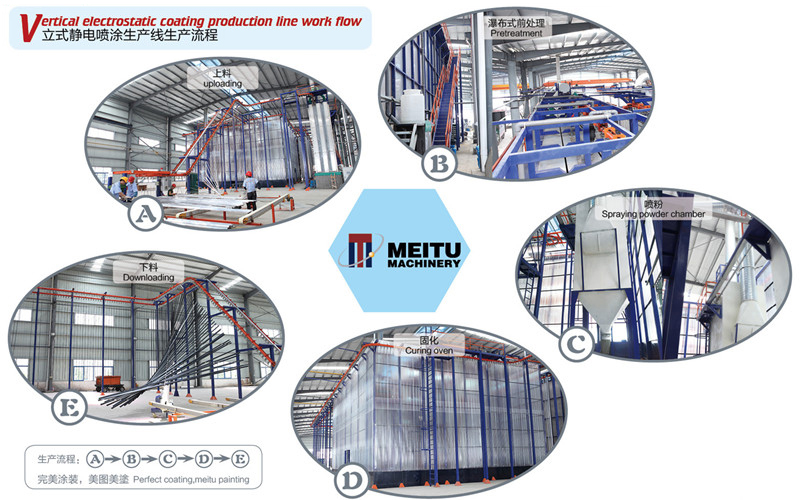

The aluminium coated powder plant working flow :

Loading -pretreatment - dripping- drying - curing oven- powder coating system- unloading- packing. The following picture shows that :

- Waterfall + spraying joint cleaning make better cleaning at pretreatment stage.

- Meitu patent technology "middle exhaust" to ensure that the recovery effect of powder booth reaches more than 97%,

- Clean quickly, save time and reduce cost.

Features and Advantage:

1) The conveying chain in the powder booth is shaped like "V", and the hanging device reversing mechanism is set at the middle point. When the workpiece goes through the hanging device reversing mechanism, the workpiece rotates smoothly 180°, and the workpiece does not collide with each other, so as to complete the spraying of the workpiece on both sides of the single powder room, saving manpower, material resources and financial resources.

2) The side plate of powder booth is made of PP board,use the latest technology and they are the first one to do this new booth in a powder coating vertical line field. When changing the color and cleaning the powder room, the air knife will automatically reciprocate the cleaning. The PP plate use the German brand Simonan. Can be better to anti-electronica.It is easier to clean.

3) Powder dusting room powder recovery using domestic innovative single pipe cyclone recovery design, the first level big cyclone recycling rate reach to 97%. The waste powder rate also decreased 5% than other suppliers.

4) Powder filtration recovery adopts filter element type filter two-stage recovery system, which is composed of 32 sets of filter elements.

Quality Compliance:

Council LVD directive 2014/35/EU

Full Automatic Coating powder Design Data :

|

Coating workpieces: |

window frame and other aluminum workpiece |

|

Maximum work piece size: |

250mm×100mm×L6500mm |

|

Standard weight: |

3.0KG /piece |

|

Energy source: |

gas |

|

Reference capacacity: |

1800T-2200T |

|

Standard chain speed: |

3.0m/min |

|

Deionized water flow: |

5m3 /h |

|

The space of work piece: |

66mm、100mm、133mm、200mm |

Other Products

Post requirements