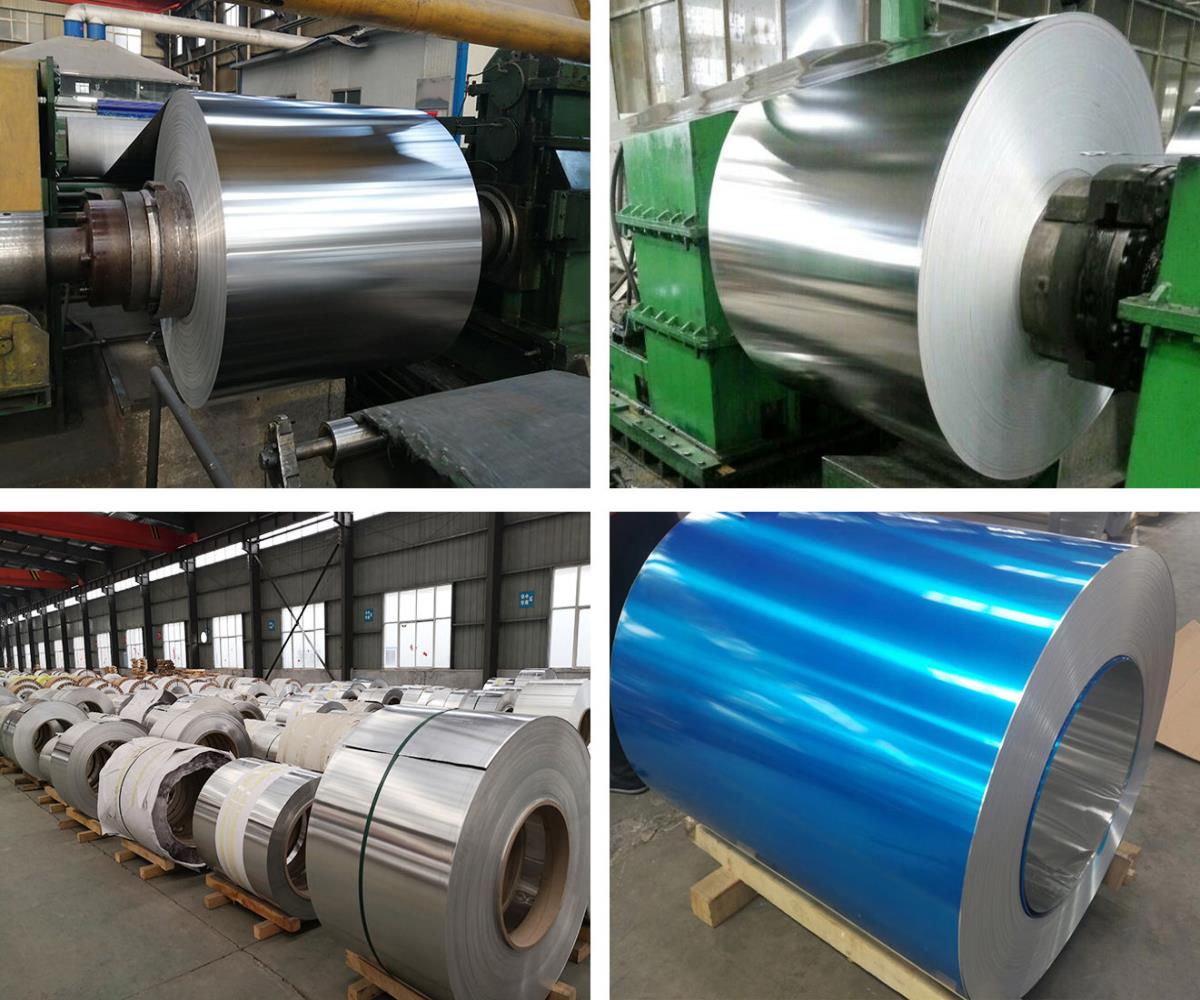

Aluminium Coil

By: Henan Hongchang Aluminum Co., Ltd.| Alloy | 1060, 1100, 3003, 3004, 3105, 5052, 8011, etc |

| Temper | H32 H34 H36 H42 H111 H112 H116, etc |

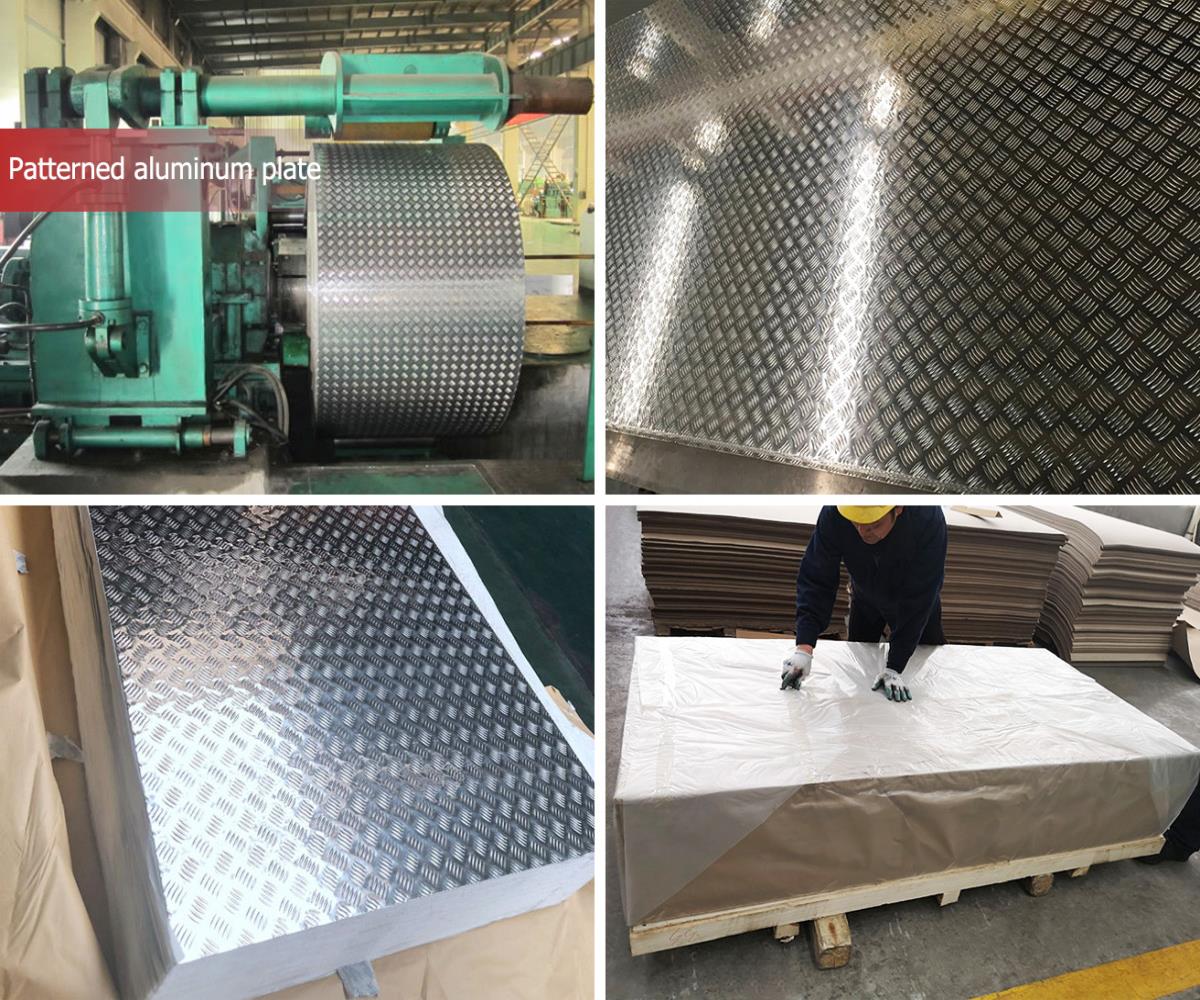

| Surface | Mill, Bright, Polished, Hairline, Embossed, Etching |

| Thickness | 0.15-4.0mm |

| Width | 20-2650mm |

| Length | C |

| Core Diameter | 505/508 |

| Category | Industrial Coil |

| Manufacturer | Henan Hongchang Aluminum Co., Ltd. |

| Min Order Quantity | 1.00 MT |

| Delivery Lead Time | 35 days |

| Price | 3105.00 |

| Place of Origin | Zhengzhou, China |

| Supply Ability | 200000 t/a |

| Packaging Details | Standard Export Wooden Box |

| Transportation Details | Sea / Air |

Description

Cold rolled aluminium coil usually refers to the cold rolled aluminium coil processed by the cold rolling process of cast rolled materials, which is usually called cast rolled aluminium coil. Cold rolling is a common metal processing process. It is to reduce the thickness of the material and improve its surface quality and mechanical properties by further processing at room temperature or slightly below room temperature after the metal is heated (usually hot rolled). As for the aluminium coil casting process, it may be relatively simple. Aluminium ingot---aluminium liquid---static furnace---cast rolled coil, which is a conventional processing process for raw materials.

Cold-rolled aluminium coils are more inclined to non-heat treatment processes. For example, our common 1060 aluminium coils, 3003 aluminium plates, 3105 aluminum coils, 5052 aluminium plates, 1100 aluminium plates, etc. are all cold-rolled aluminium coils, which are suitable for simple stamping, but not suitable for large-scale finished product stamping. Therefore, the main application areas are currently mainly concentrated in building exterior walls, signs and signs, etc.

Features of Cold - Rolled Aluminium Coil:

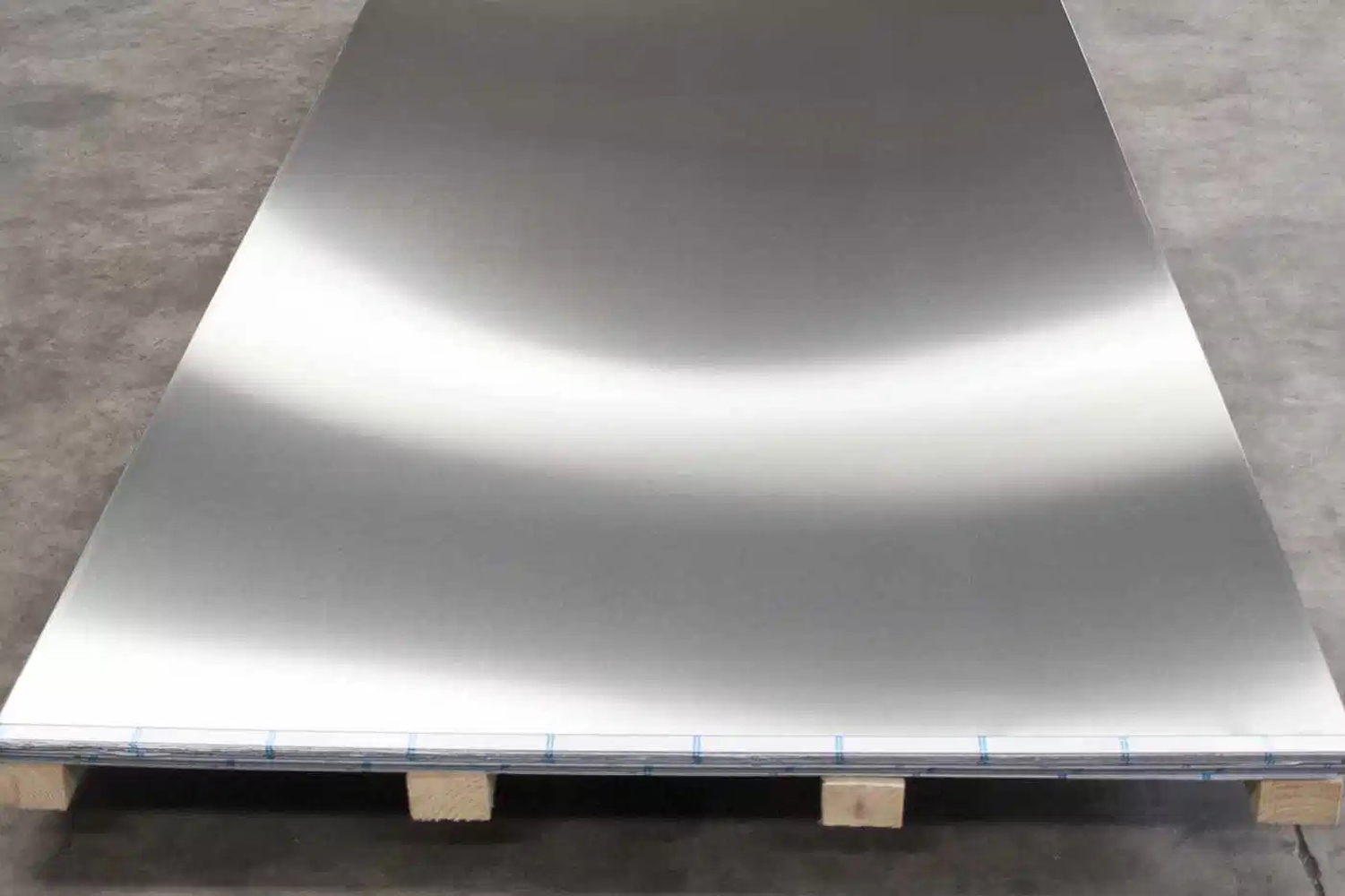

1. High surface finish: The cold rolling process can improve the surface quality of the aluminium coil, making it smooth and shiny.

2. High thickness accuracy: The thickness of the cold-rolled aluminum coil can be very precise, suitable for applications with strict thickness requirements.

3. Excellent mechanical properties: The cold rolling process can improve the strength and hardness of aluminium, especially in applications that require high strength.

4. Good processability: Due to its good strength and ductility, cold-rolled aluminium coils are easy to process in the future, such as shearing, stamping, stretching, etc.

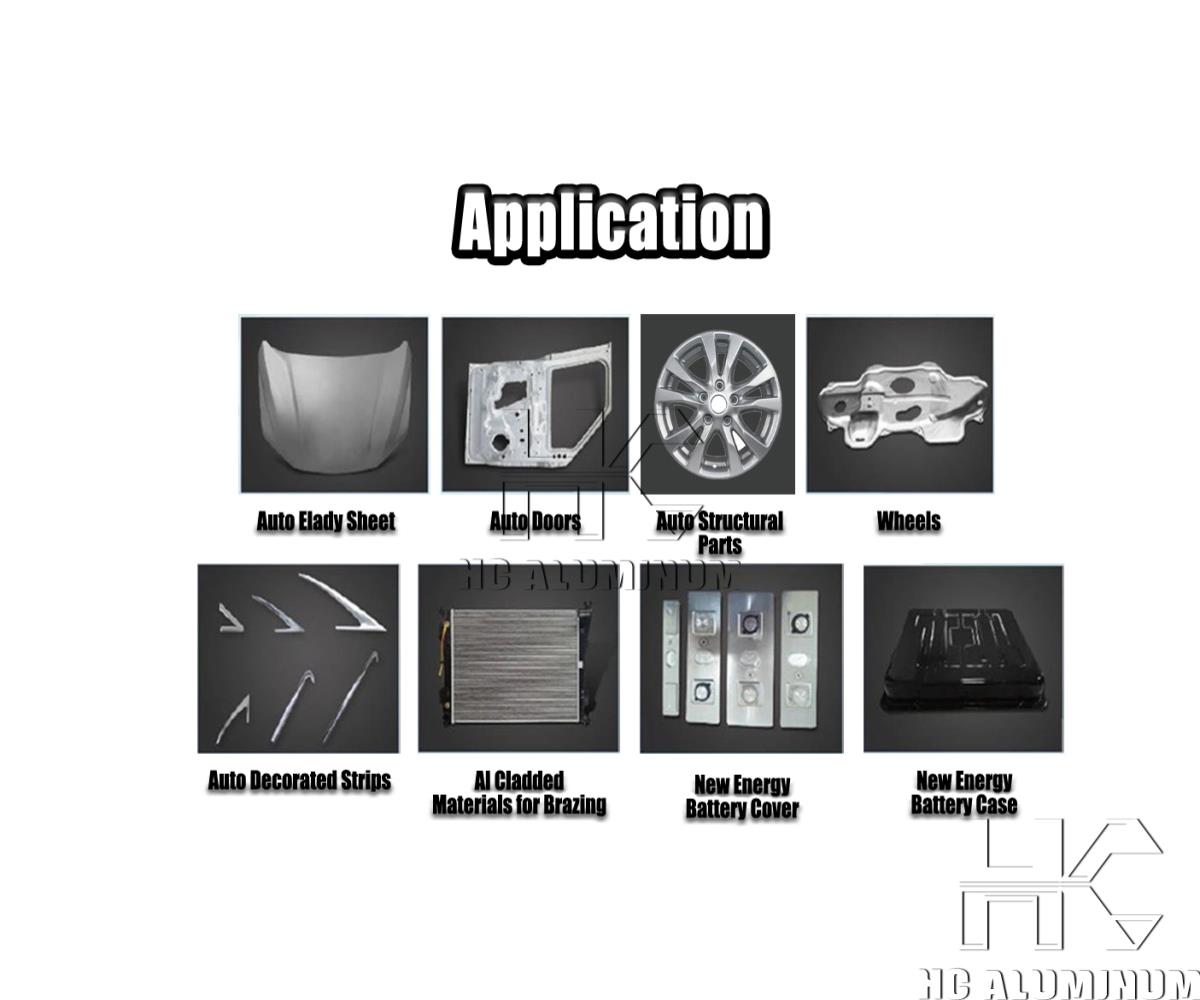

Application Areas:

- Building materials: used for building materials such as roofs, wall panels, curtain walls, etc

- Automotive industry: body panels, auto parts, etc

- Electronic products: shells of mobile phones, laptops, etc

- Home appliance industry: shell materials for home appliances such as refrigerators and washing machines

- Packaging industry: such as beverage cans, food packaging, etc

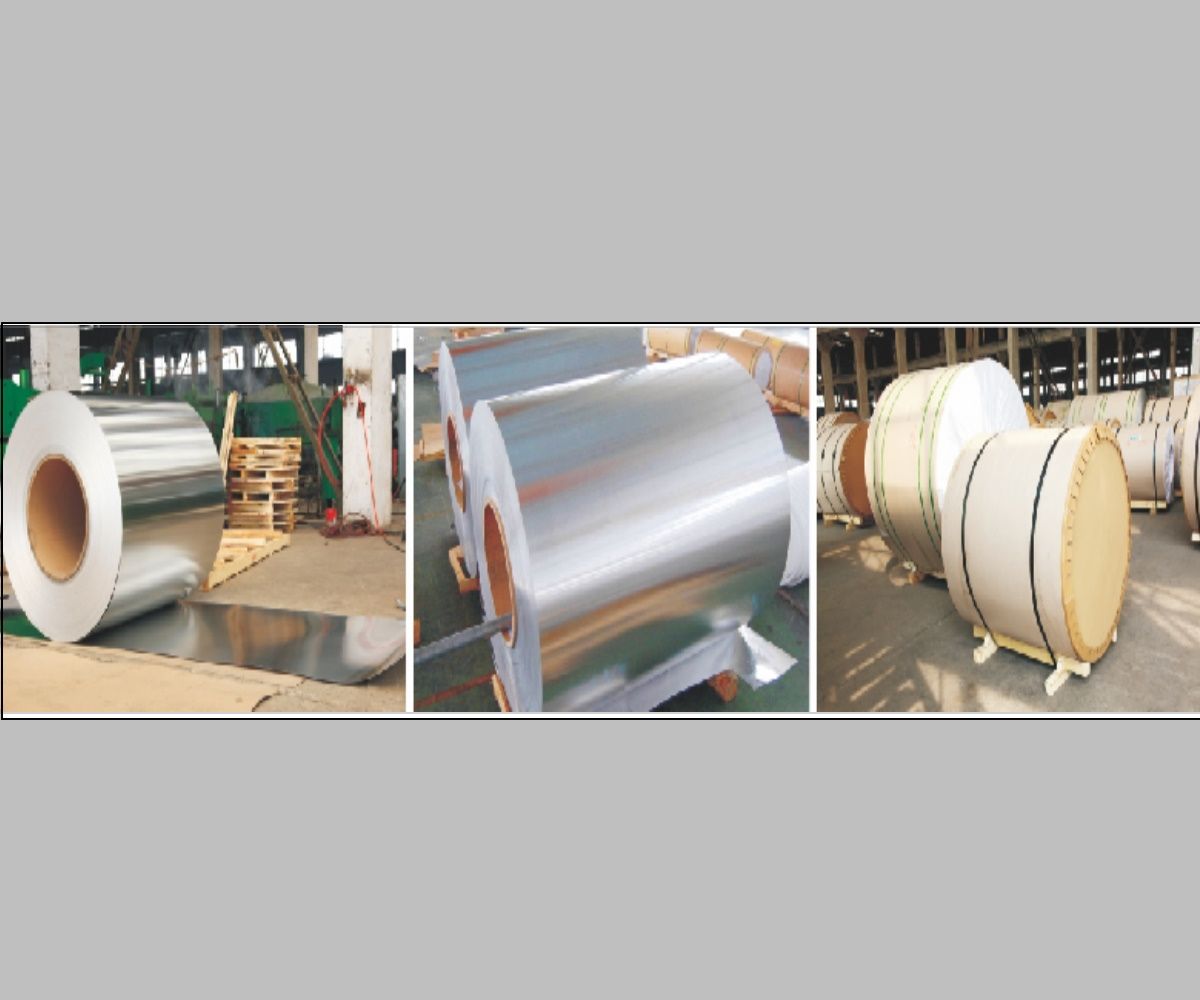

Packaging:

Export packaging of aluminium coils: Export packaging usually adopts the fumigation well frame method, which is fixed with steel belts on the outside. The aluminium coil has a double-layer moisture-proof rain cloth on the outside, and the inside is protected from moisture-proof agents. It adopts sealed packaging, which is suitable for sea transportation.

Other Products

You may be interested in

Post requirements