600mm HP Graphite Electrode

By: Henan KFCC Carbon Co.Ltd| Price | Available on request |

| Category | Others |

| Manufacturer | NA (Trader) |

| Min Order Quantity | 10.00 MT |

| Delivery Lead Time | As per order |

| Place of Origin | China |

| Supply Ability | Customization as required |

| Packaging Details | Standard export packing |

| Transportation Details | Road / Ship |

Description

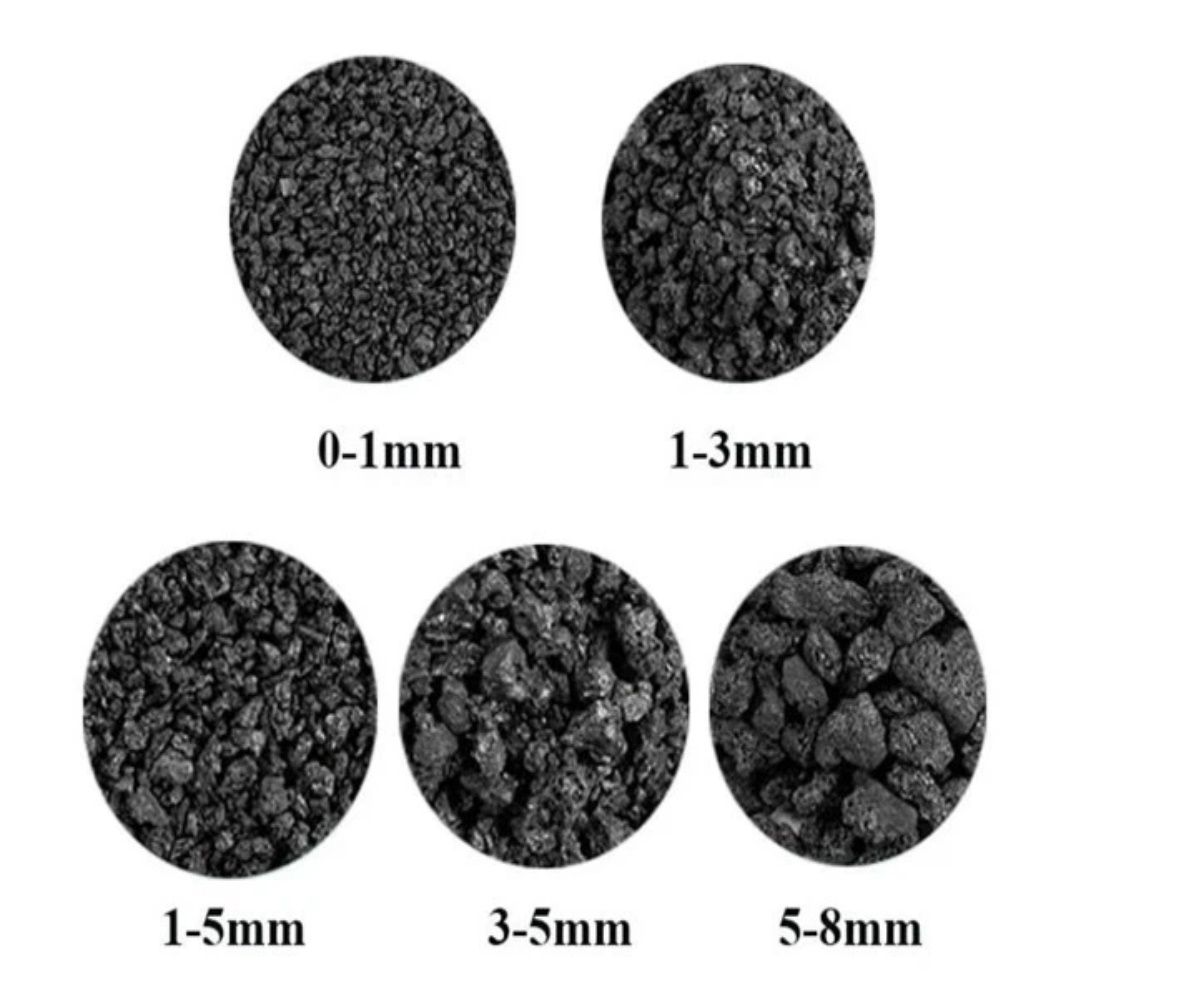

Calcined petroleum coke is widely used in various industries, so it must have a wide range of uses.

It can also be seen in many industries. The calcined petroleum coke can be used in graphite manufacturing, smelting and chemical industry according to its quality. Low sulfur, excellent coking coke, such as needle coke, is mainly used in the manufacture of high power graphite electrodes and some special carbon products; Needle coke is an important raw material for steel industry to develop new technology of electric furnace steelmaking. During the reaction, coke powder particles are continuously drawn from the reactor and into the coke burner. Some coke particles are burned with air and recirculated back into the reactor to provide the heat needed for the coking reaction, and excess coke powder particles are expelled from the system. Calcined petroleum coke is used in refining aluminum and making graphite. In addition, it is mainly used in the manufacture of carbon products, such as graphite electrodes and anode arcs, as well as steelmaking, non-ferrous metals and aluminum smelting. You can see it in all of these places. In addition, calcined petroleum coke can also be used as fuel, but when used as fuel, superfine grinding is required using a graded impact mill.

The graphite electrode production process can be divided into three kinds: pressure vibration method, numerical control automatic forming method and mechanical processing method. The main method used in the general die production in China is the mechanical processing method.

According to the national standard, graphite electrode can be divided into ordinary power graphite electrode, high power graphite electrode and ultra-high power graphite electrode.

1, ordinary power graphite electrode (RP), allowing the current density to be lower than 17A/cm2, raw materials are mainly petroleum coke, coal tar pitch, production cycle of about 45 days, mainly used to smelting ordinary steel, silicon and yellow phosphorus.

2, high power graphite electrode (HP), it allows the current density between 18~25A/cm2, raw material for petroleum coke, coal tar pitch, add needle coke, production cycle is about 60 days, mainly used for steelmaking.

3, ultra-high power graphite electrode (UHP), it allows the current density to be greater than 25A/cm2, raw materials including petroleum coke, needle coke, coal tar pitch, the needle coke content is greater than high power graphite electrode, production cycle is greater than 65 days, used for smelting fine steel, special steel.

Other Products

Post requirements