700mm UHP Graphite Electrode

By: Henan KFCC Carbon Co.Ltd| Price | Available on request |

| Category | Others |

| Manufacturer | NA (Trader) |

| Min Order Quantity | 10.00 MT |

| Delivery Lead Time | As per order |

| Place of Origin | China |

| Supply Ability | Customization as required |

| Packaging Details | Standard export packing |

| Transportation Details | Road / Ship |

Description

Graphite electrode is a major conduction material used in the electric smelting industry, which has the properties of superior electric conductivity, thermal conductivity, high mechanical strength, oxidation, and corrosion resistance in high temperatures.Graphite electrode is widely used in EAF (for smelting steel),submerged-arc furnace (for producing Ferro alloy, pure silicon, phosphor, matte, calcium carbide, etc.)and electric resistance furnace, (such as graphitization furnace producing graphite electrodes, glass--melting furnace, electric furnaces producing carborundum, etc.)

Electric furnace steelmaking is the use of graphite electrode into the furnace current, strong current in the electrode at the bottom of the gas arc discharge, the use of the heat generated by the arc to smelting. According to the capacity of electric furnace, different diameter graphite electrodes are used. In order to make continuous use of electrodes, electrodes are connected by electrode thread joints. The graphite electrode used in steelmaking accounts for about 70 ~ 80% of the total amount of graphite electrode.

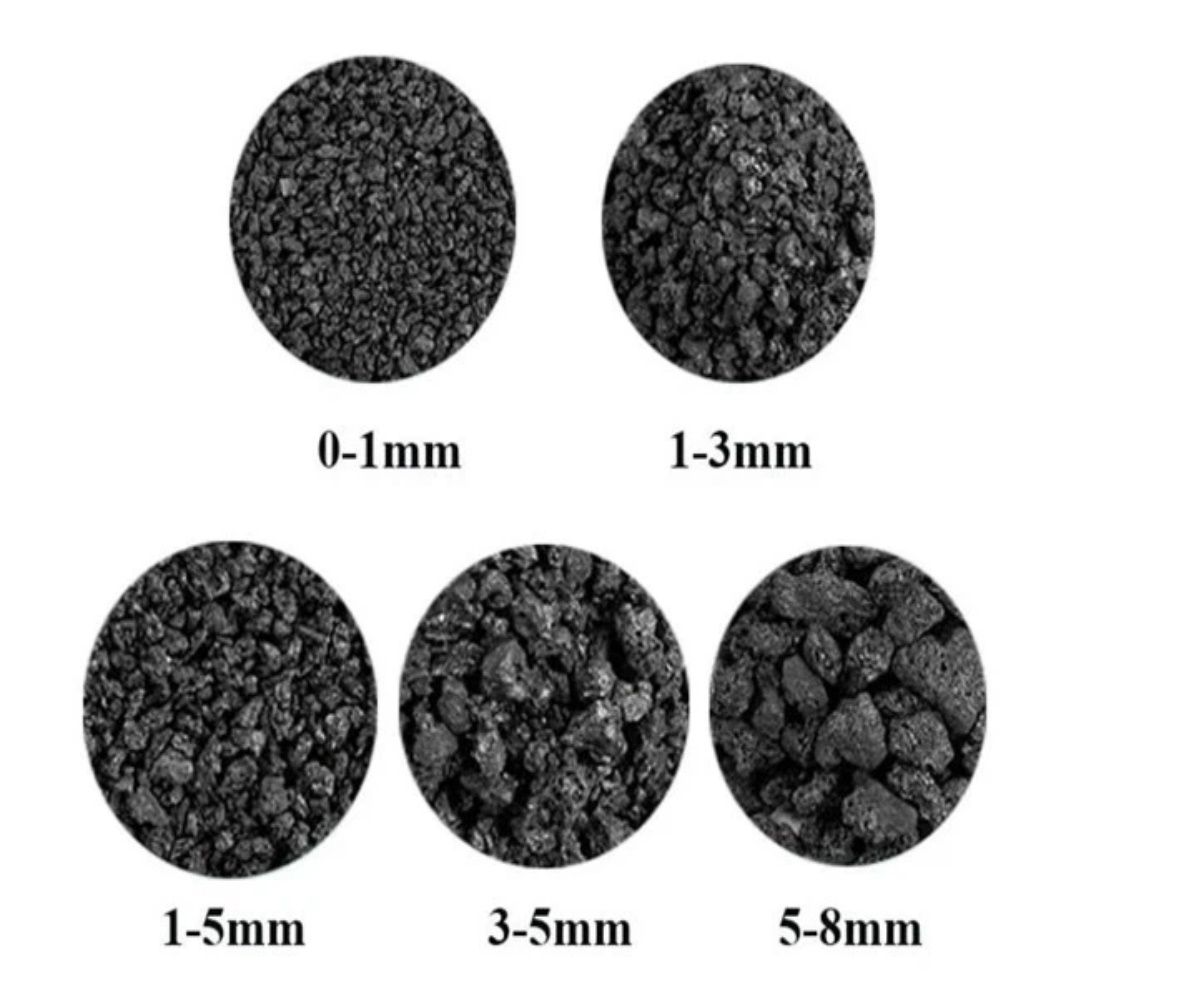

UHP graphite electrode is used for the recycling of steel in the electric arc furnace industry. Its main ingredient is high-value needle coke which is made from either petroleum or coal tar. Graphite electrodes are finished with a cylinder shape and machined with threaded areas at each end. In this way, the graphite electrodes can be assembled into an electrode column using.

UHP graphite electrode must be produced by high grade needle coke, and its gravitational heat treatment should be carried out in the inner series graphitization furnace. The graphitization temperature is up to 2800 ~ 3000°C, so the resistivity is lower, allowing a larger current density, the linear expansion coefficient is smaller, with excellent thermal shock resistance.

Calgon Carbon products include eleven categories and fifty-six varieties, mainly graphite electrodes, graphite anodes, carbon blocks, special carbon products, carbon fiber products, etc., which are widely used in metallurgy, chemical industry, machinery, electronics, medical and new materials. Products are exported to Europe, America, Southeast Asia, Africa, and 40 other countries and regions.

Other Products

Post requirements