Aluminium Plate 7075

By: Huizhou Qide Metal Material Co.Ltd| Price | Available on request |

| Category | Aerospace Defence Marine Plate |

| Manufacturer | NA ( Trader) |

| Min Order Quantity | 25.00 MT |

| Delivery Lead Time | As per Order |

| Place of Origin | China |

| Supply Ability | Customization on Requirement |

| Packaging Details | Standard Export Packing |

| Transportation Details | Road/Ship |

Description

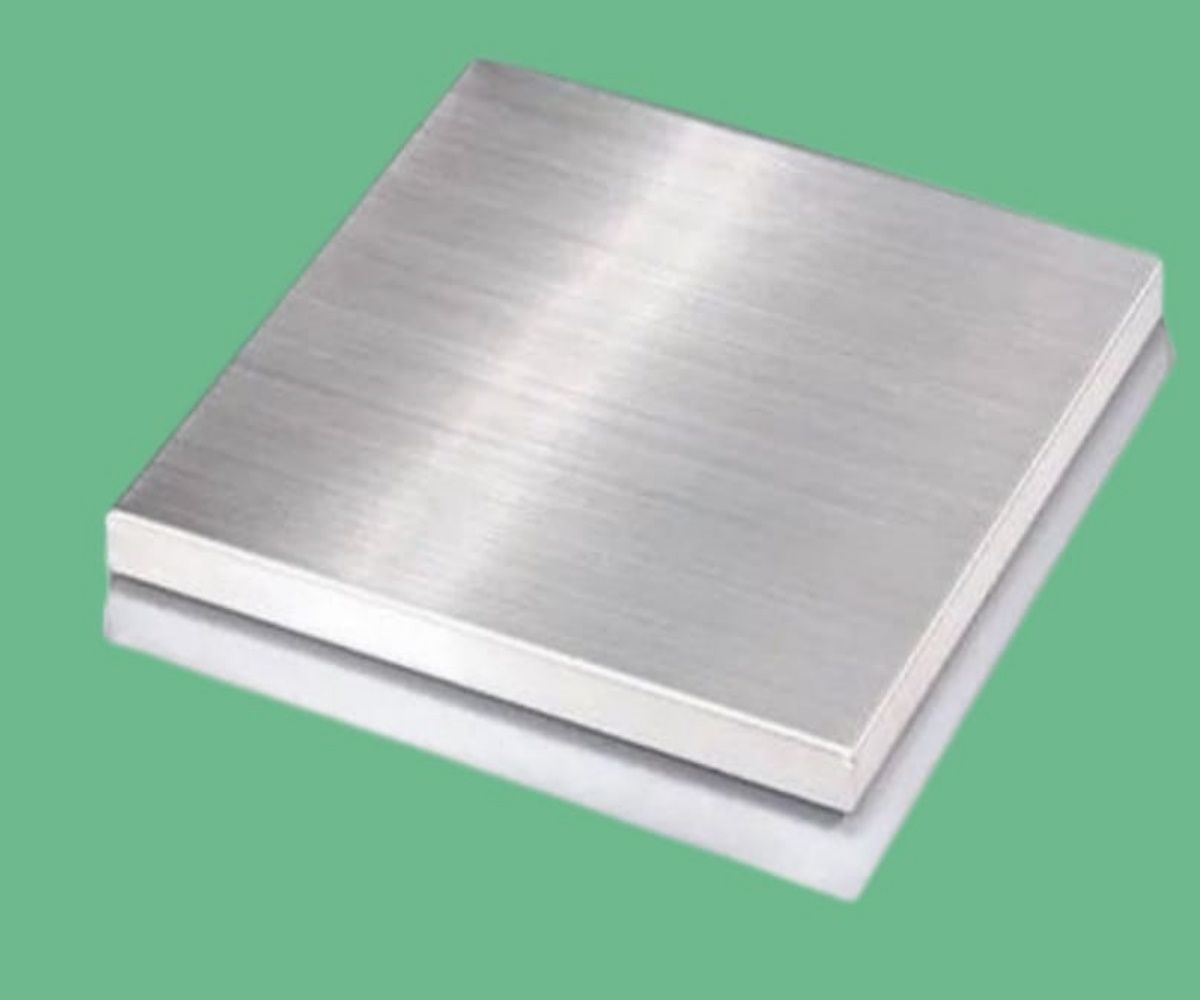

7075 aluminium plate is a cold-treated forged alloy with high strength, far superior to mild steel. 7075 is one of the strongest alloys commercially available. Normal corrosion resistance, good mechanical properties and anodic reaction. The finer grains provide better deep drilling performance, enhanced tool wear resistance and differentiated thread rolling.

7075 aviation aluminum features:

1. High strength heat treatable alloy.

2. Good mechanical properties.

3. Good usability.

4. Easy to process and good wear resistance.

5. Good corrosion resistance and oxidation resistance.

Corrosion resistance:

7075 aluminum plateHas moderate corrosion resistance. Compared with tempers T6 and T651 , T7351 and T73 have very good resistance to stress corrosion cracking. (Note: Direct contact with dissimilar metals can cause galvanic corrosion).

Oxidative:

using commercial oxidation methods,7075 aluminum plateThe anodic oxidation reaction grade is good. It can perform both hard oxidation and solid color coating oxidation.

Processability:

7075 aluminum plate excellent machinability when machining with single-point or multi-axis diamond tools on automatic lathes. A chip separator is recommended. The alloy is rated " B " in the Aluminum Institute's Machinability Grade Standard, produces curved or brittle chips, and has a good to excellent finish.

Other Products

You may be interested in

Post requirements