Aluminium Extrusion Services

By: MY GROUP ALÜMİNYUM| Price | Available on request |

| Category | Fabrication and Installation Services |

| Manufacturer | NA (Service Provider) |

| Place of Origin | Turkey |

Description

Aluminum extrusion is the definition of shaping material by forcing aluminum to flow through a hole shaped in a mold. The shape of the mold after extrusion is applied throughout the aluminum. Aluminum extrusion can basically be compared to squeezing a toothpaste tube and taking the shape of the cap hole with the resulting paste. Here, pre-heating the aluminum tickets during the extrusion process allows the aluminum to be shaped easily and the press pressure to be reduced.

What are the Stages of Aluminum Extrusion?

The use of aluminum profiles as raw materials in the process is defined as billet.

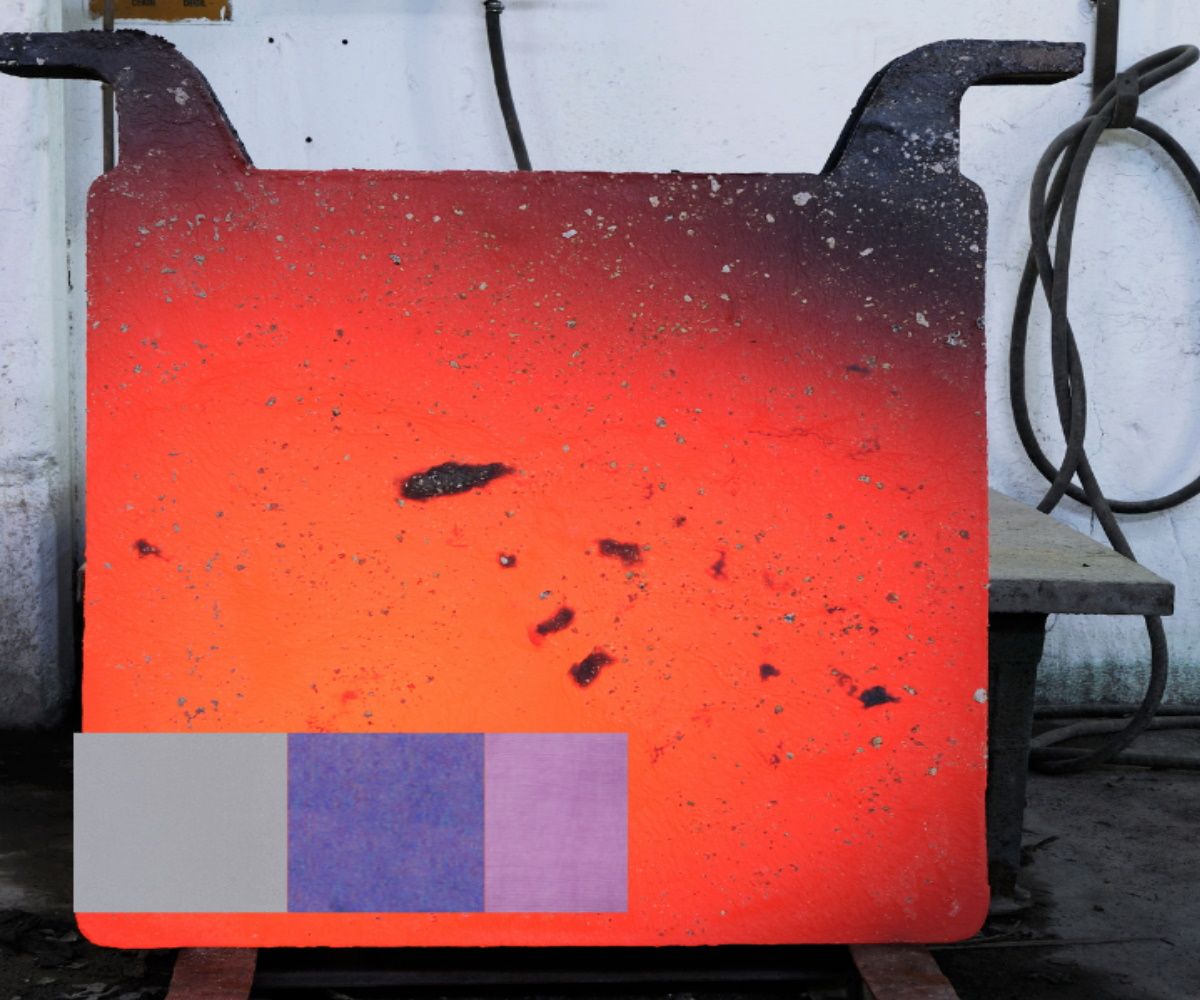

Aluminum billets are heated to 350 -500°C.

After the aluminum billet reaches the desired temperature, the lubricating material is transferred onto it as a thin film.

Due to the heat, the mold and the material are prevented from sticking to each other.

The bill is then transferred to the carrier.

While the aluminum billet billets are in full contact with the bearing walls, they are crushed by the opposite mold. The aluminum is pushed through the mold. Liquid nitrogen flows around the mold to cool the process. Nitrogen gas is also used instead of liquid nitrogen.

As a result of the pressure, the billet is squeezed out of the cavity of the aluminum mold. After the extrusion process, the temperature is measured instantly and noted.

During extrusion, cooling is carried out through a series of fans as long as the extrusion outlet cooling table.

The oxidized part on the billet billet is discarded.

When the extrusion reaches the desired length, the aluminum extrusion profile is cut with the help of a saw. Transfer is provided on a metal cooling table.

Cooling is done. After the cooling process, aluminum hardening and alignment process is carried out.

Then, in the cutting saw, the extrusion is transferred to a stretched saw blade and cuts are made using certain lengths. The cutting tolerance on the saw is approximately 0.8 cm.

How to Extrude Aluminum Profile?

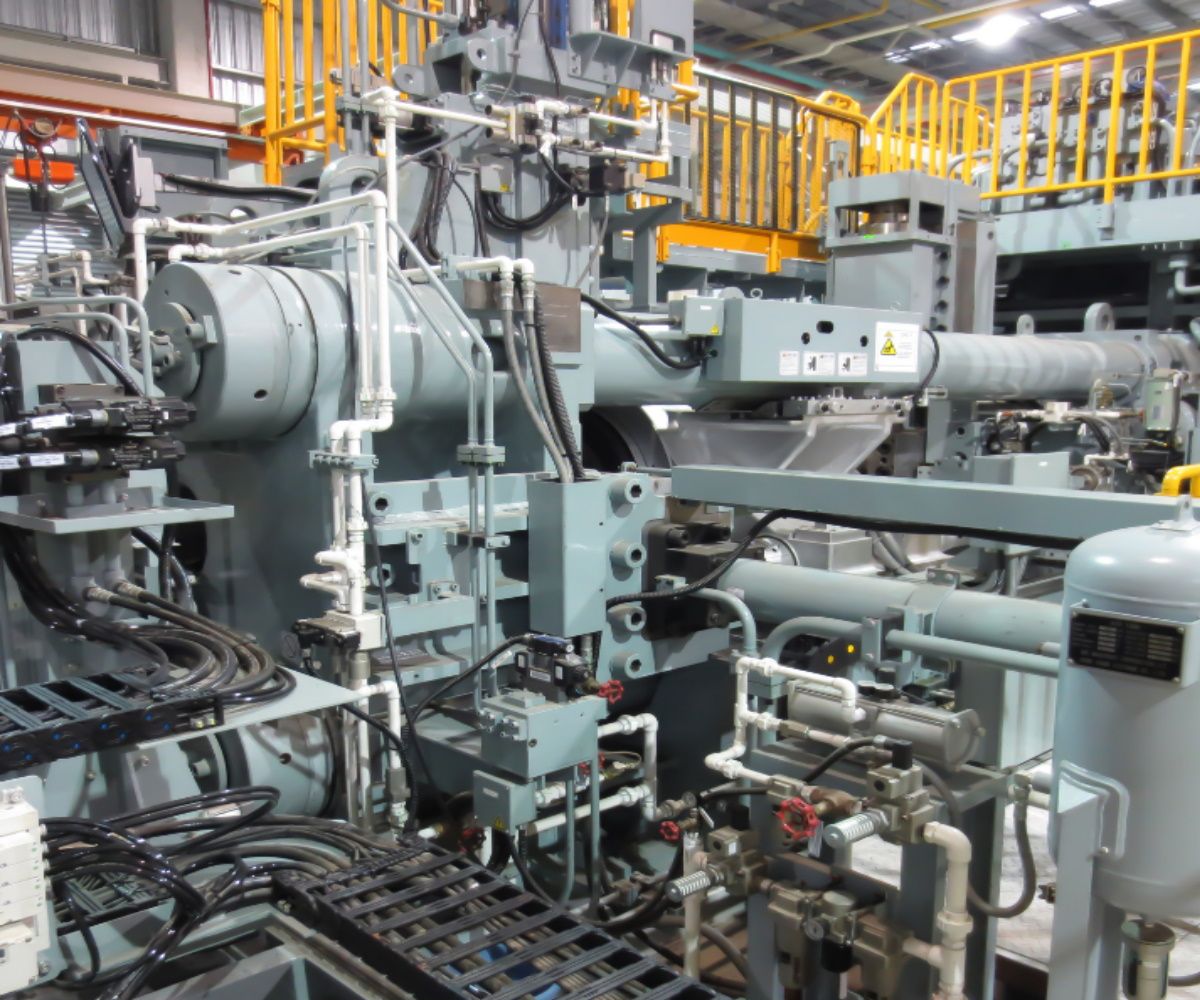

Aluminum profile extrusion is applied through aluminum extrusion presses. As the carrying capacity of the press increases, billet diameters also increase. Thus, maximum mold sizes are increased.

The first stage of the aluminum profile extrusion process is to obtain a mold, which is a piece of metal used to obtain the desired aluminum shape. After this process, the aluminum billet piece is heated and forced into the mold with the help of a steel piston. The extruded aluminum is then placed on a long table to be transported to the cooling area.

Aluminum extrusion process can be done cold and hot. This cooling process is carried out with water and air. After the cooling process, the roughly shaped aluminum extrusion profile is flattened. It is then placed in aging furnaces for heating and hardening.

Other Products

You may be interested in

Post requirements