Aluminium Anodizing Services

By: MY GROUP ALÜMİNYUM| Price | Available on request |

| Category | Aluminium Surface Treatment Services |

| Manufacturer | NA (Service Provider) |

| Place of Origin | Turkey |

Description

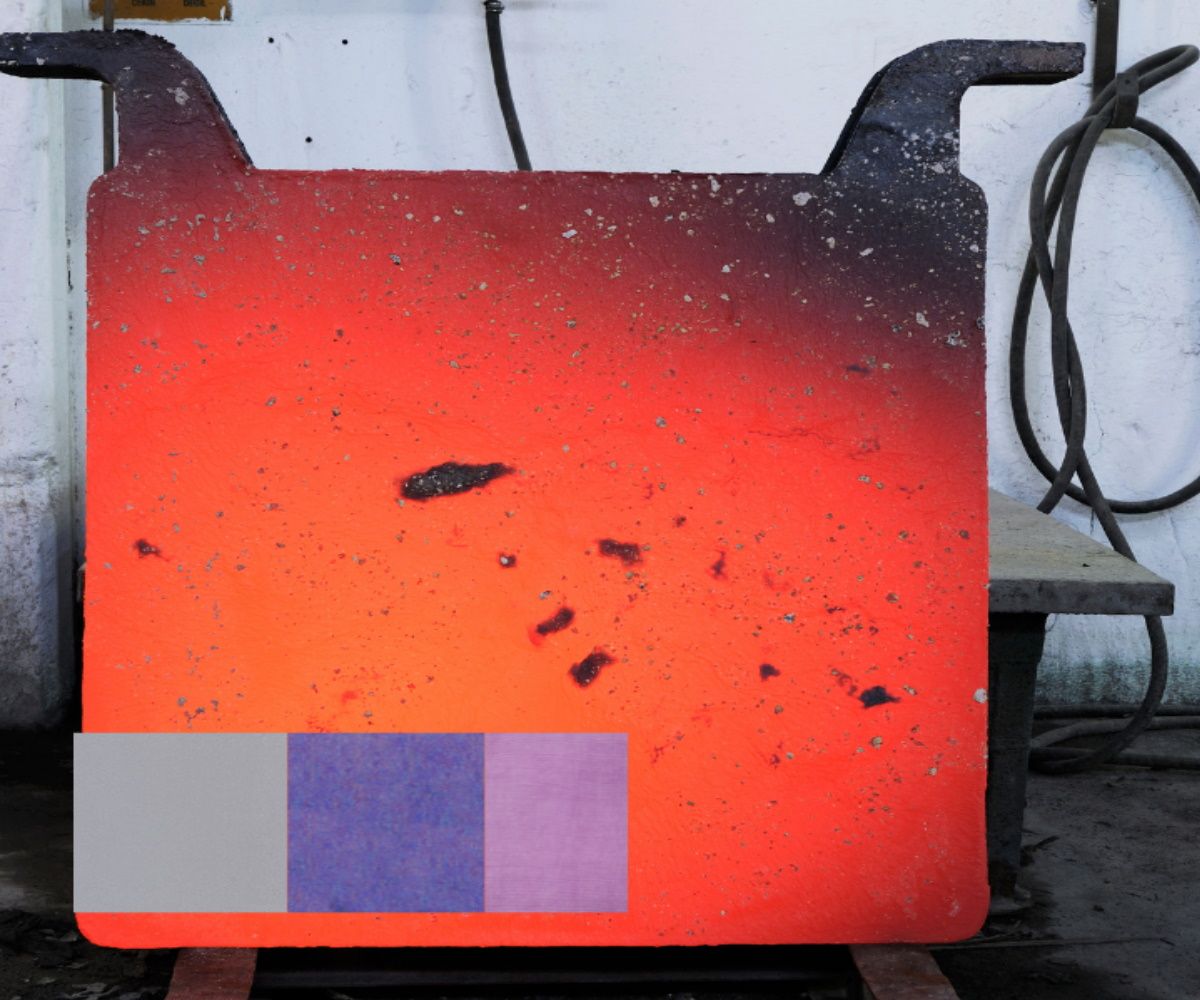

Aluminum profiles produced especially for architectural purposes must also present a good decorative appearance. This decorative appearance is achieved by anodic oxidation, that is, anodizing coating, which is a type of oxidation process. Normally, the thickness of the oxide layer formed on aluminum is between 1-2 microns, but with the process, this value increases to 10-25 microns, and in addition to the decorative appearance, the resistance of the material to corrosion is guaranteed. The process is simply performed by dipping the aluminum profile as an anode into an acidic electrolyte and passing direct current between the anode and cathode. The electrolyte dissolves with the reaction and forms as an oxide layer on the surface of the profile. The sulfuric acid direct current method is the most commonly applied anodizing coating technique. The surface treatments applied to the profile before coating determine the desired decorative appearance as matte or glossy.

It is also possible to color it according to the area of use or preference. The applied paint makes the material more durable. Anodizing, which is a completely recyclable application, does not harm the environment and does not lose its financial value even when it is scrap.

Anodizing was first used on an industrial scale in 1923 to protect seaplane parts from corrosion. Oxalic acid anodizing was first patented in Japan in 1923 and was later widely used in Germany, especially in architectural applications.

The processes carried out in our anodizing facility are under the guarantee of the European QUALANOD specification and TSE, with features such as lifetime, UV resistance and color permanence.

Our production facility has the latest technology. In addition to our standard colors, optional color works are carried out in our pools.

Our company is sensitive to the environment and human health; Meets ROSH and REACH requirements.

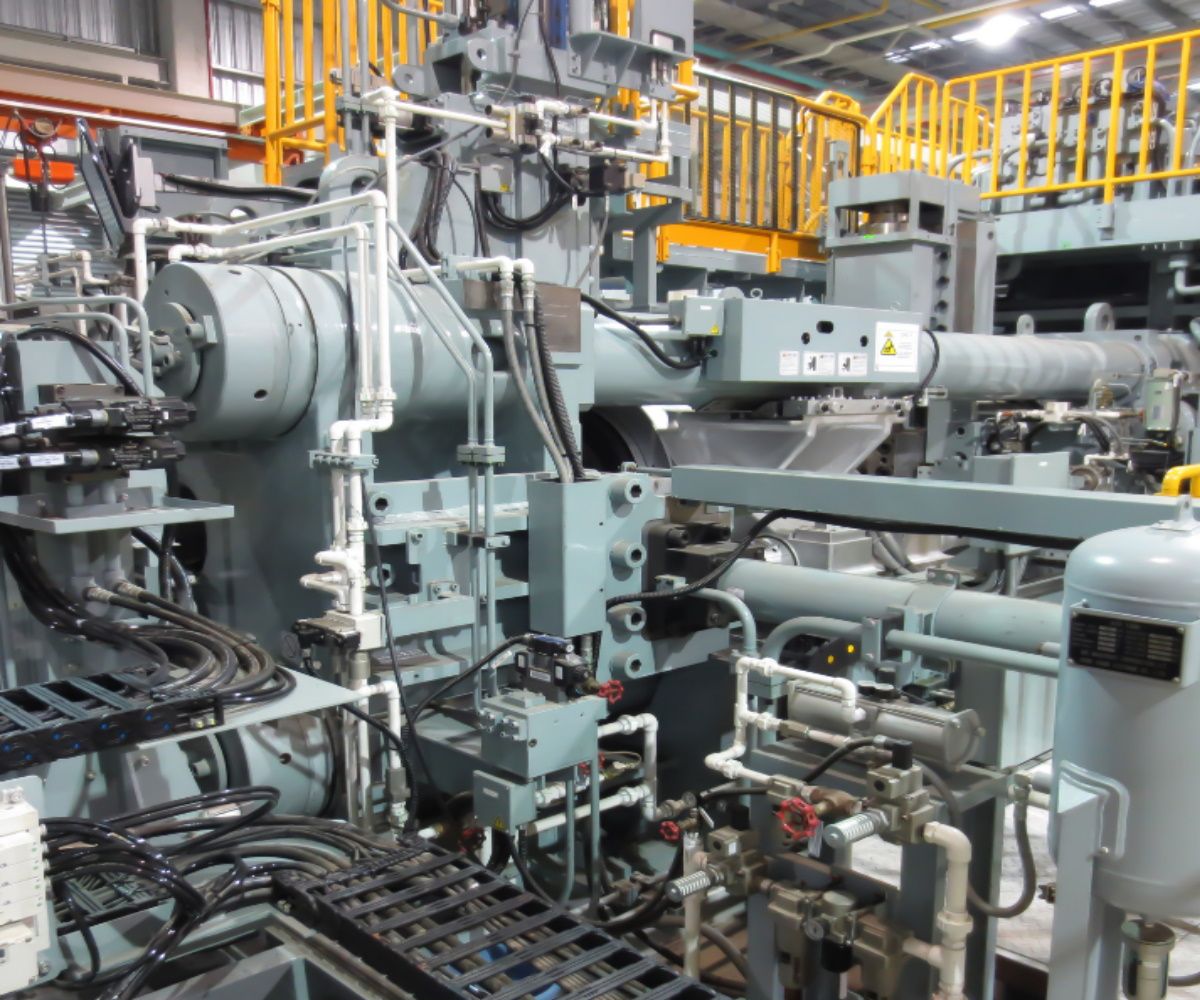

Special Anodizing Facility

The weight of aluminum profiles and parts is much less than stainless steel. In addition, processing effort and cost are more advantageous than stainless steel. Therefore; It is preferred to use special or hard anodized aluminum materials against corrosive liquids in many areas such as machine parts, defense industry, aviation and automotive.

In this facility; Hard and special anodizing processes can be performed in thicknesses between 5 µm and 80 µm, with hardness up to 400 HV and gloss values in the range of 500 - 1000 depending on demand.

Other Products

Post requirements